CATEGORY

Injection Molding Services

Injection molding machine is used for fabricating items from plastic trinkets and toys to automotive body parts, cell phone cases, water bottles, and containers.

Beroe LiVE.Ai™

AI-powered self-service platform for all your sourcing decision needs across 1,200+ categories like Injection Molding Services.

Market Data, Sourcing & Supplier Intelligence, and Price & Cost Benchmarking.

Schedule a DemoThe World’s first Digital Market Analyst

Abi, the AI-powered digital assistant brings together data, insights, and intelligence for faster answers to sourcing questions

Abi is now supercharged with GPT4 AI engine. Enjoy the ease of ChatGPT, now on Abi

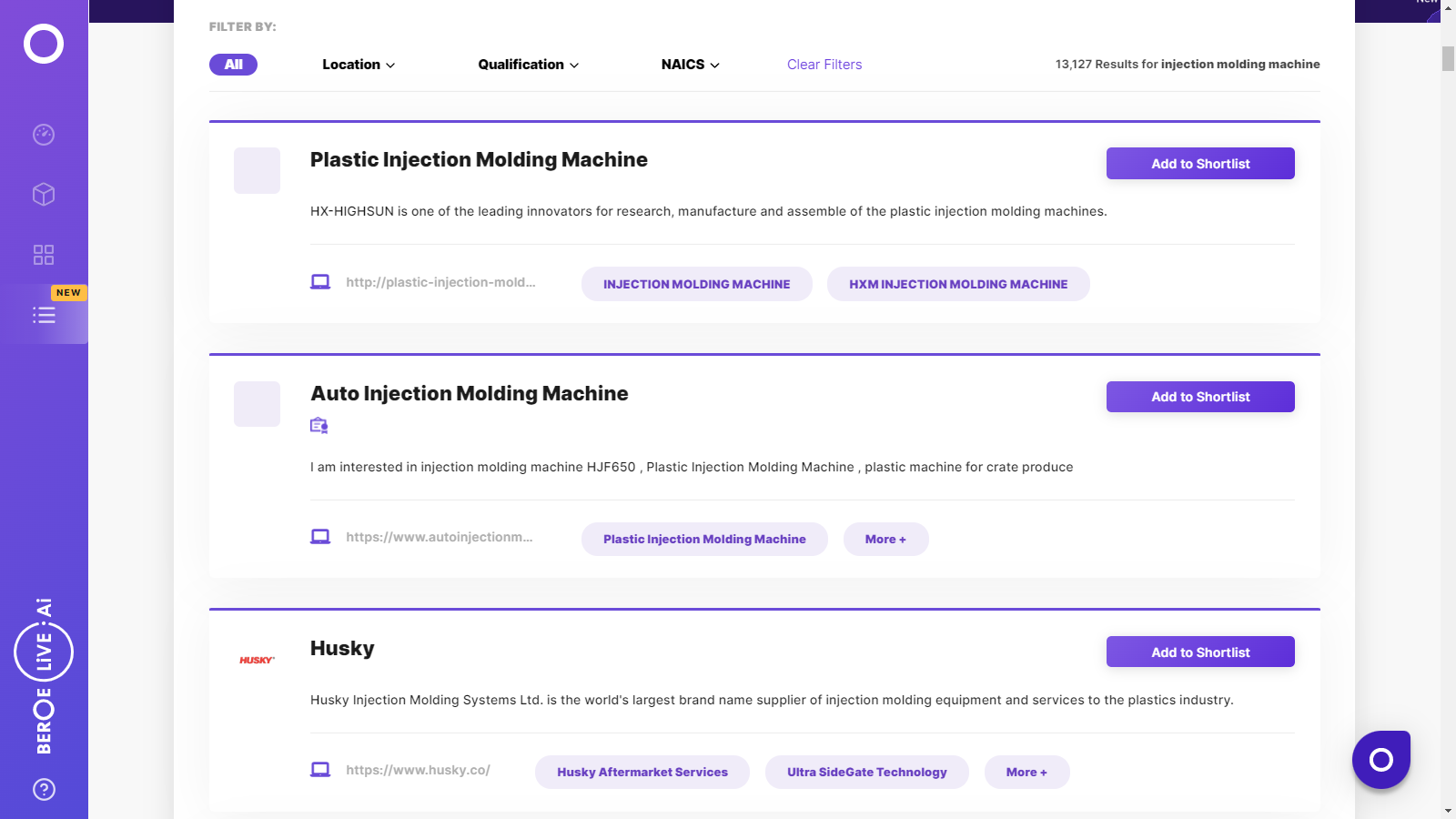

Injection Molding Services Suppliers

Find the right-fit injection molding services supplier for your specific business needs and filter by location, industry, category, revenue, certifications, and more on Beroe LiVE.Ai™.

Schedule a Demo

Use the Injection Molding Services market, supplier and price information for category strategy creation and Quaterly Business Reviews (QRBs)

Schedule a DemoInjection Molding Services market report transcript

Injection Molding Services Global Market Outlook

-

The APAC accounts for a dominant share of approx. 40 percent, supported by the strong demand from varied end-use markets, low-cost labor availability, and abundant supply of raw materials, etc.

-

Though the manufacturing activity has resumed during the COVID-19 scenario, concerns surrounding third wave of infections are posing a threat to the industry

-

The global injection molding market is highly fragmented, and hence, the buyer power is high. Due to volatile raw material prices, the suppliers also have high bargaining power

Impact of COVID-19 on Injection Molding Services Industry

-

Amid the COVID-19 pandemic, majorly suppliers are currently operating at capacities on par with the OEM demand requirements. Demand from key end-use segments such as packaging, automobile, electrical/electronics, etc., have relatively increased during Q2 2021 and are further improving during Q3 2021, thereby showing no significant gap between supply–demand and price of the product.

-

Globally, supply–demand gap is balanced in Q2 2021, as contract manufacturers are operating at capacities on par with OEM’s demand requirements. The demand from end-use industries, such as packaging, automotive, electronics, healthcare, etc., have relatively increased during Q2 2021, however, there are no significant supply constraints witnessed in the market.

Global Injection Molding Services Market: Drivers and Constraints

Industry Drivers

-

End Use Demand: Increasing adoption of plastic components by industries, such as automotive, electronics, healthcare, etc., is expected to support the demand for injection molded components and encourage innovation, in terms of materials, technologies, etc.

-

Emerging Economies: Buyers interest are shifting gears in looking for sourcing from low-cost regions, such as Eastern Europe, Mexico, South East Asia, etc., thereby driving the market in emerging economies

-

Eco-friendly and Recycled Feedstock: Bio resins, environmental friendly raw materials, and recycled raw materials provide thrust to drive the market, amidst environmental impact

Constraints

-

Economic Downtrend: Scheduled production cuts across OEMs, owing to COVID-19 pandemic, coupled with ongoing semiconductor chip shortage, have resulted in economic uncertainties across the globe, thereby leading to a downtrend in injection molding market growth

-

Raw Material Price Fluctuations: Suppliers are susceptible to commodity price fluctuations (especially for high mix, low volume industries), against which they cannot hedge, due to their relatively lower volumes of raw material purchase. These are expected to impact supplier margins and final price of product

-

Environmental Impact: Stringent policies imposed by various government to avoid usage of plastic would certainly create strain in the industry’s growth

Interesting Reads:

Discover the world of market intelligence and how it can elevate your business strategies.

Learn more about how market intelligence can enable informed decision-making, help identify growth opportunities, manage risks, and shape your business's strategic direction.

Get Ahead with AI-Enabled Market Insights Schedule a Demo Now