CATEGORY

Warehousing Sourcing Best Practices Turkey

Beroe LiVE.Ai™

AI-powered self-service platform for all your sourcing decision needs across 1,200+ categories like Warehousing Sourcing Best Practices Turkey.

Market Data, Sourcing & Supplier Intelligence, and Price & Cost Benchmarking.

Schedule a DemoThe World’s first Digital Market Analyst

Abi, the AI-powered digital assistant brings together data, insights, and intelligence for faster answers to sourcing questions

Abi is now supercharged with GPT4 AI engine. Enjoy the ease of ChatGPT, now on Abi

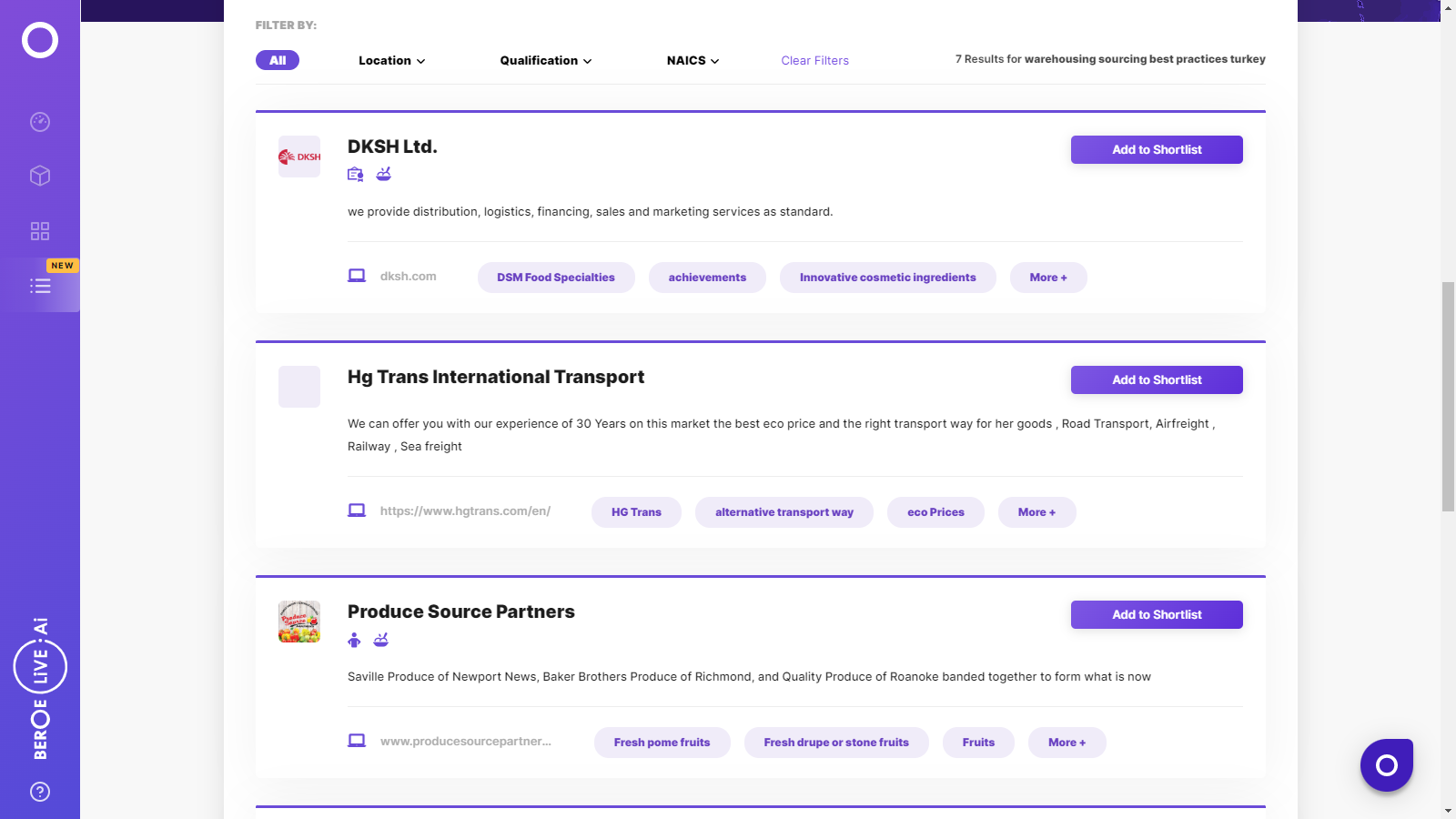

Warehousing Sourcing Best Practices Turkey Suppliers

Find the right-fit warehousing sourcing best practices turkey supplier for your specific business needs and filter by location, industry, category, revenue, certifications, and more on Beroe LiVE.Ai™.

Schedule a Demo

Use the Warehousing Sourcing Best Practices Turkey market, supplier and price information for category strategy creation and Quaterly Business Reviews (QRBs)

Schedule a DemoWarehousing Sourcing Best Practices Turkey market report transcript

Regional Market Outlook on Warehousing Sourcing Best Practices

Warehousing buyers predominantly own/lease the facility in case of bigger and long-term operations, whereas operations usually of less complexity and volume are usually outsourced.

Closed Book Contracts with Activity-based Unit Pricing Mechanism

- Highly adopted to standardized operations and suitable for completely outsourced warehouse sourcing model

- Risk is completely owned by 3PL and hence, 3PL expects higher profit margin

- Activity-based unit rates are fixed based on order profile and volume assumptions

Open Book Cost Plus Management Fee Pricing Mechanism

- Highly adopted in case of outsourcing only the operations to 3PL, while the facility is still owned/leased by the buyer

- Risk is completely owned by the buyer and hence, 3PL expects low margin of 6–8 percent

- To overcome the high risk and 3PL spirit, buyers offset the risk using gain share programs

How does buyers and 3PL manage the labor cost increase for warehousing services?

Both buyers and 3PLs adopt combination of process improvement methods, automation technologies, and contract negotiation techniques in order to keep in check the labor cost involved in warehousing operations.

Turkey Logistics Market Overview

The 3PL market is expected to grow by approx.3 percent to reach TRY 40.9 billion in 2018, where the demand is driven by the 3PL companies expansion and consumer goods industry.

- Turkey 3PL market is estimated to be around TRY 39 billion in 2017 and is expected to grow at a CAGR ~3 percent over the next two years

- The 3PL market is primarily driven by the automobile sector and major leasing activities by 3PLs, retails and e-commerce companies. Local firms, such as Ekol, Mars, Omsan, and Netlog, dominate the market, due to the growing demand for their services from retailers

- The Turkey contract logistics market is estimated to be around TRY 13 billion in 2017 and is expected to grow at a CAGR of 4.8 percent over the next two years

- The logistics market is primarily driven by automotive, iron and steel industry and also from retail business

Outlook on Key Cost Drivers for 3PL

Labor Cost

- Wage rate in Turkey for logistics sector has increased by 10–15 percentage in 2017

- This is predominantly due to inflation and increased demand in locations, like Istanbul, Kocaeli, for skilled labor in the supply chain and freight forwarding industry

Depreciation for Plant and Equipment

- In recent times, major logistics players in Turkey have increasingly invested in new locations and equipment, hence it would be reflect as higher depreciation cost in the operating expense

Software and other Intangible Assets

- Capital expenditure on technological investment has increased, gradual raise in upgraded technology matching shippers demand and solving the increased supply chain complexity are the primary drivers of technological investment

Utility Cost

- Utility is one of cost drivers, where industrial consumers paid average 25.4 kurus per kWh electricity, which is approx. 1 percent increase compared to 2016

- With increasing inflation, demand from the logistics and retail business, the utility cost is likely to increase by 2 percent in 2018

Rentals for Occupancy

- In 2016–2017, rentals rate has increased by 2 percent annually in major locations, like Istanbul and Kocaeli

- With supply, demand remaining stable and with increasing take up transactions, the rental rates are likely to decrease in 2018

Warehouse Sourcing Practices – FMCG Industry

Major FMCG companies in Turkey adopt ‘owned/leased facility and outsourced operations' and ‘complete outsource to 3PL' sourcing strategies for the warehousing operations in Turkey.

FMCG companies adopt following sourcing models in Turkey:

- Client owned/leased facility and outsourced operations

- Complete outsourced to 3PL

This decision is effected by multiple factors, such as land prices for the given region, initial investment/already existing facility, available space for investment, 3PL service provider agreements for coverage.

Methodology Adopted to Manage the Labor Cost Increase

Both buyers and 3PLs adopt combination of process improvement methods, automation technologies, and contract negotiation techniques in order to keep in check the labor cost involved in warehousing operations.

Process Improvement:

Time, energy, opportunity cost, and space impact the overall labor costs in warehousing. Adopting process improvement programs can mitigate and reduce these costs by avoiding higher picking time, unnecessary repetitive movements, rework, and returns

Methodology

- Continuous improvement projects

- Performance for performance

- Other productivity measures

Technology Investment

Buyers and 3PLs invest in technology to integrate with the warehousing operations in order to increase the visibility, leading to higher efficiencies and correspondingly lower variable costs.

Methodology

-

Software

- Voice recognition

-

LMS

-

Automation equipment

- AGV/Robots

- ASRS

- Conveyor belts

Contract Negotiation - SLA

3PL suppliers tend to increase the price, due to inflation on labor (or any other cost driver) throughout the contract period. To avoid this type of increase, buyers can introduce certain clauses and techniques to reduce the labor cost and align in line with inflation increase.

Methodology

- Gain sharing

- Performance-based incentive

Process Improvements Programs

The industry should engage and assess supplier for continuous improvement programs during supplier evaluation process and mandate suppliers to include success case studies related to continuous improvement programs during evaluation.

Continuous Improvement Programs

As a process improvement program, 3PLs adopt continuous improvement projects, such Kaizen, Lean, TQM, Six Sigma, Lean Six Sigma in order to mitigate the overall cost increase in warehousing operations

Reason for adopting these practices in Turkey

These systems are implemented with purposes, such as workflow simplification, increased productivity, cost (direct and indirect) reduction, HSE benefits (due to simplified environment), and risk mitigation.

Pay for Performance and Other Productivity Measures

- Performance-based compensation program

- Activity-based engineered standards

- Demand-driven workforce flexibility

Above are the major process improvement programs adopted by 3PL's to mitigate cost increase

Reason for adopting these practices in Turkey

- Main purpose is to increase the labor efficiency, productivity, and less turnover, due to employee satisfaction and ownership

- Incentive pay (or pay-for-performance) type of improvement generally require LMS (either software or in a basic format)

Interesting Reads:

Discover the world of market intelligence and how it can elevate your business strategies.

Learn more about how market intelligence can enable informed decision-making, help identify growth opportunities, manage risks, and shape your business's strategic direction.

Get Ahead with AI-Enabled Market Insights Schedule a Demo Now