CATEGORY

Industrial Washing Machines for Pharmaceutical Applications

Industrial washers used to be durable and efficient and capable of providing the right finish. Unlike domestic washing machines, heavy duty Industrial washing machine incorporate sophisticated programs, CNC controlled to obtain repeatability of the washing effects.

Beroe LiVE.Ai™

AI-powered self-service platform for all your sourcing decision needs across 1,200+ categories like Industrial Washing Machines for Pharmaceutical Applications.

Market Data, Sourcing & Supplier Intelligence, and Price & Cost Benchmarking.

Schedule a DemoThe World’s first Digital Market Analyst

Abi, the AI-powered digital assistant brings together data, insights, and intelligence for faster answers to sourcing questions

Abi is now supercharged with GPT4 AI engine. Enjoy the ease of ChatGPT, now on Abi

Industrial Washing Machines for Pharmaceutical Applications Suppliers

Find the right-fit industrial washing machines for pharmaceutical applications supplier for your specific business needs and filter by location, industry, category, revenue, certifications, and more on Beroe LiVE.Ai™.

Schedule a Demo

Use the Industrial Washing Machines for Pharmaceutical Applications market, supplier and price information for category strategy creation and Quaterly Business Reviews (QRBs)

Schedule a DemoIndustrial Washing Machines for Pharmaceutical Applications market report transcript

Global Market Outlook on Industrial Washing Machines for Pharmaceutical Applications

- Steam heating and electrical heating washers are the most commonly used washers in the pharmaceutical industry

- The heating system is mainly used for heating water to near boiling point to achieve thermal dis-infection and also to heat the air to dry the load at the end of the wash cycle

Steam Heating

- Fast thermal exchange capacity

- Lower energy consumption

- Shorter cycle time

- Fast removal of residues

- Efficacy of the washing system on both cleaning of chemical soils and reduction of the microbial charge

- Achieve higher bio-burden log reductions

Suppliers: Steris Corporation, Fedegari Group, IWT, Belimed, Girton

Electrical Heating

- Longer cycle time

- Lower performance

- Higher energy consumption

Suppliers: Steris Corporation, IWT, Belimed, Girton

Technology Innovations

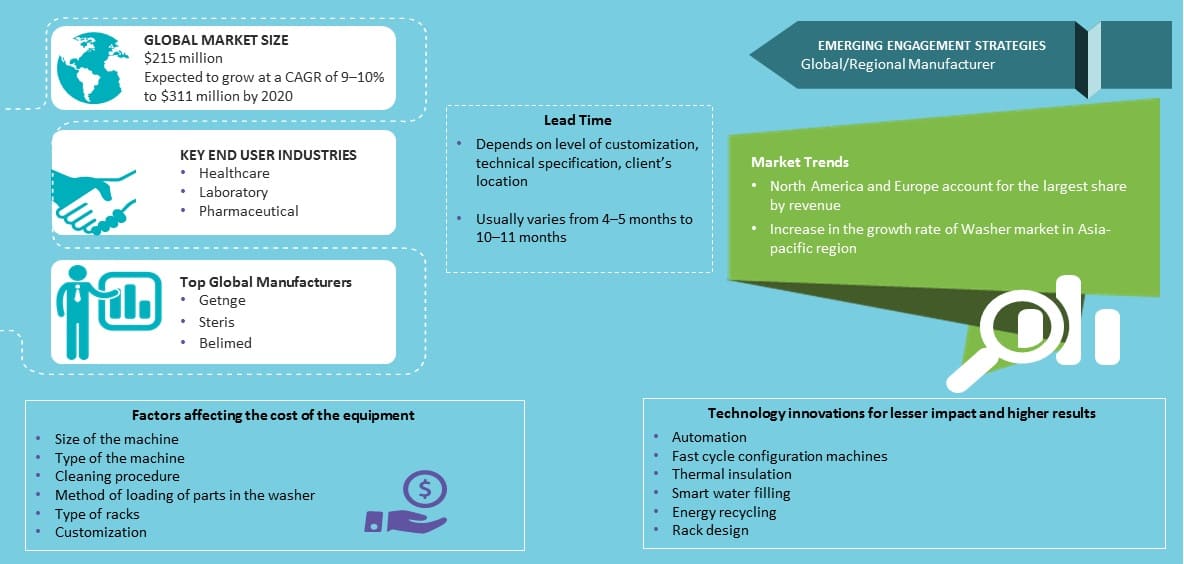

Due to higher demand for lesser footprint washing machines, the suppliers are including green engineering for washer design, so as to achieve lower impact, improved resource efficiency, and higher results

Turbo Drying System

- This system controls drying air inlet for a HEPA filtered hot air recirculation inside washing chamber

- The air circulation creates high turbulence air flow inside the chamber, leading to reduction in drying times

- The system facilitates the total elimination of water both inside and outside of the instruments

- Supplier: Steelco

Fast Cycle Configuration Machine

- Performs a complete and validated instrument washing, disinfection, and drying cycle in 30 minutes

- It has a big capacity pre-heating tanks connected to the chamber, which helps in cycle reduction

- The water recirculation tank recycles the disinfection water into next washing cycle, which helps in reduction of energy and water consumption

- Supplier: Steelco (DS 800, DS1000)

Thermal Insulation

- The wash chamber is insulated with thick fiberglass insulation with a vapor-barrier covering top, door, and bottom of chamber to minimize noise and heat loss, leading to reduction in electricity consumption

- Supplier: Steris (Reliance 680 PG)

Smart Water Filling

- Continuous adjustment of usage of water per phase depending on the load

- The washer is engineered to dose detergent as a function of how much water is present, so as to achieve the correct concentration

- Less load leads to less amount of water and detergent, resulting in reduction of water and detergent consumption

- Supplier: Belimed (WD230, WD250)

Rack Design

Rack Design has a major role on the effectiveness of water distribution throughout the chamber and the cleaning ability of the washer:

- Retained water volume inside the rack- lesser retain of water leads to reduction of volume of water per phase

- Rack capacity- greater rack capacity enables more trays to be processed per load, which leads to reduction in number of times the washer has to run, resulting in reduction of operation costs

- Supplier: Belimed (Eco series racks) (It has 10% lower internal volume compared to the traditional ones)

Energy Recycling

Recycle of heat energy generated from the previous drying cycle:

- The heat energy generated from the previous cycle is used to heat the incoming water entering the chamber for the next phase. Hence, less energy would be used for heating the water for the next phase

- The cold incoming water would act as a condenser for the hot air coming out from the chamber, leading to removal of moisture from the air, prior to entering the exhaust system.

- Supplier: Belimed

Supply Market Outlook

Industrial Washer Supplier Perspective

Market Outlook

- The market for disinfectors is expected to grow at a CAGR of 10.2% 2014–2020 to reach an estimated value of $3,116.5 million in 2020. The washers market is expected to reach about $215 million in 2017

- Hospitals and clinical segment is expected to achieve the highest growth rate during this period, due to the increased number of hospitals with rising number of surgeries

- North America and Europe market account for the largest share by revenue, and it is mainly due to the large number of disinfectors manufacturers in these regions. A significant growth has been seen in the Asia-pacific region because of rising incidences of diseases, coupled with an increase in population

Supplier

- The major players in these market are: Steris, Getinge, Belimed, Steelco, etc.

- Due to stricter rules and regulations, the global players are investing a lot on technological innovations for reducing impact on the environment and increasing efficiency

- Due to huge competition, the suppliers are increasing their service portfolio. For example: Extended warranty, replacement of parts, preventative maintenance agreements, etc.

Engagement Trends

Preference given to global players compared to local ones because of the following:

- Product quality

- Product compliance with latest rules and regulations

- Maintenance services

- High level of customization for different applications

Interesting Reads:

Discover the world of market intelligence and how it can elevate your business strategies.

Learn more about how market intelligence can enable informed decision-making, help identify growth opportunities, manage risks, and shape your business's strategic direction.

Get Ahead with AI-Enabled Market Insights Schedule a Demo Now