CATEGORY

3D Printing Services

The 3D printing process builds a three-dimensional object from a computer-aided design (CAD) model, usually by successively adding material layer by layer.

Beroe LiVE.Ai™

AI-powered self-service platform for all your sourcing decision needs across 1,200+ categories like 3D Printing Services.

Market Data, Sourcing & Supplier Intelligence, and Price & Cost Benchmarking.

Schedule a Demo3D Printing Services Industry Benchmarks

Savings Achieved

(in %)

The average annual savings achieved in 3D Printing Services category is 10.30%

Payment Terms

(in days)

The industry average payment terms in 3D Printing Services category for the current quarter is 105.0 days

Compare your category performance against peers and industry benchmarks across 20+ parameters on Beroe LiVE.Ai™

Category Strategy and Flexibility

Engagement Model

Supply Assurance

Sourcing Process

Supplier Type

Pricing Model

Contract Length

SLAs/KPIs

Lead Time

Supplier Diversity

Targeted Savings

Risk Mitigation

Financial Risk

Sanctions

AMEs

Geopolitical Risk

Cost Optimization

Price per Unit Competitiveness

Specification Leanness

Minimum Order Quality

Payment Terms

Inventory Control

The World’s first Digital Market Analyst

Abi, the AI-powered digital assistant brings together data, insights, and intelligence for faster answers to sourcing questions

Abi is now supercharged with GPT4 AI engine. Enjoy the ease of ChatGPT, now on Abi

3D Printing Services Suppliers

Find the right-fit 3d printing services supplier for your specific business needs and filter by location, industry, category, revenue, certifications, and more on Beroe LiVE.Ai™.

Schedule a Demo

Use the 3D Printing Services market, supplier and price information for category strategy creation and Quaterly Business Reviews (QRBs)

Schedule a Demo3D Printing Services market frequently asked questions

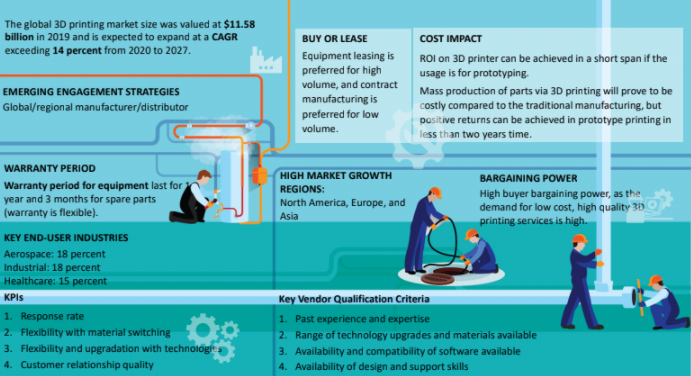

The aerospace, defense, and construction industries are the early adopters of 3D printing technology and are growing at an average CAGR of 15-25 percent. Fashion and energy are among the emerging industries that adopted the technology and are growing at an average CAGR of 15-25 percent. As per Beroe's 3D printing market trends and analysis reports, the mass customization offered by 3DP has been the predominant growth-driver for the fashion and energy industries.

3D printers are used in limited quantities for rapid prototyping and direct part manufacturing in the consumer electronics, medical devices, and aerospace sectors. They are also used to make functional and presentation models, pattern making on casting, and preparing new designs.

The supply market in the global 3D printing market is categorized into four types ' 3D printer manufacturers ' companies that supply 3D printers and associated maintenance services 3D manufacturing systems and service providers ' offer 3D systems as well as printing services Service providers ' only offer printing services CAD, 3D modeling, and design platforms providers ' These companies offer tools, software packages, which help in creating, editing, and sharing CAD files

The industries that have been adopting 3DP and contributing to the market growth are aerospace, defense, industrial construction, jewelry and fashion industries, automotive industry, etc.

3D Printing Services market report transcript

Global Market Outlook on 3D Printing Services

- Increasing investment in advanced manufacturing technologies, growing automotive industry, presence of major players, and a stable economy are propelling the additive manufacturing market revenue in North America.

- The highest demand in Europe comes from small and medium-sized businesses (SMB) that require high-speed, reliable, and low-cost prototypes.

- Strong demand for 3D printing hardware in China, the government promotion of new-age technologies in manufacturing, and rising demand for customized products are key driving factors in Asia.

- The significant reduction in manufacturing cost will help push the 3D printing market even further, thereby allowing 3D printing services to take place on a global scale.

3D Printing Market Analysis: Drivers and Constraints

Drivers

Relative design freedom

-

“Complexity is free”

-

Ability to design forms and structures not possible with traditional techniques

-

Ability to produce more efficient forms for injection molding

-

Ability to reduce the number of assembled parts in a finished item

-

Use of digital warehousing

Faster design cycles and shorter lead times

- Shorter cycle time from design through market test and redesign

Mass customization

-

Cost of producing 100 designs of an item in the same material is practically the same as producing one design 100 times

-

Reduction of inventory holdings

Increased supply chain resilience

- Ability to redirect supply from one site to another, virtually “at the click of a button”

Improved sustainability

- Reduction in waste during parts manufacture and the use of recyclable materials improve green credentials

Constraints

-

Limitation on the system throughput

-

Shorter range of material than traditional manufacturing

-

Different 3D printing technologies require different materials

-

Restriction of number of materials in a single print

-

Specialist skills required for design

-

Requirement for post-processing

-

Cost of materials

-

Production volumes are lower than injection molding

-

Consistency of production quality

3DP Major Technology Overview

FDM

- Use of a thin, plastic-based filament, which is heated and extruded through a print head.

- FDM is also known as material extrusion or FFF or PJP.

- It is the least expensive technology.

SLA

- Building object layers from a liquid polymer resin using ultraviolet light to cure or harden the material.

- SLA is also known as vat polymerization, vat photopolymerization.

- It was invented first.

SLS

- Uses a laser to form three-dimensional shapes from a powder material (including metal, ceramic, and plastic).

- LS is also known as powder bed fusion and EBM.

- It is the most expensive technology.

Supply Market Overview

The supply market in the 3DP industry is of four types:

- 3D printer manufacturers: Company, which supplies 3D printers and associated maintenance services. These companies do not offer outsourcing printing services

- 3D manufacturing systems and service providers: These companies offer printing services along with the 3D systems.

- Service providers: These suppliers offer only printing services, i.e., contract manufacturers.

- CAD, 3D modeling, and design platforms providers: These companies offer tools, software packages, which help in creating, editing, and sharing CAD files.

Supply Outlook

65 percent of the supply market for manufacturing industrial 3D printing systems is taken by the US

The European manufacturers accounted for 15 percent of all industrial 3DP systems

Asia is the third largest manufacturer; Israel, China, and Japan are the leading producers 3DP systems

Demand Outlook

Due to COVID-19, the healthcare industry demand for more clinical products and equipment in market

3D printing, which is a quick solution for faster production of high-volume clinical products and equipment spare parts, demand of 3D printing has been on rise

Why Should You Buy This Report?

This report on the 3D printing services market contains:

- A meticulous overview of the general market outlook

- Porter’s Five Forces analysis of the 3D printing industry trends, drivers, and restraints

- Comprehensive segmentation of the market and a fragmented assessment of each category and sub-category

- Extensive analysis of the regional and competitive dynamics driving the 3D printing market over the forecast period.

Interesting Reads:

Discover the world of market intelligence and how it can elevate your business strategies.

Learn more about how market intelligence can enable informed decision-making, help identify growth opportunities, manage risks, and shape your business's strategic direction.

Get Ahead with AI-Enabled Market Insights Schedule a Demo Now