Evolving Supply Chains in Developing Economies and the Resultant Impact

With the rapid pace of globalization, the significance of supply chain management has increased manifold. The vast diversity in economics, legislations, regulations, and standards lead to difficulties in managing supply chains. Participation in these supply chains, fueled by low value-added manufacturing activities have contributed to high rates of economic growth in many developing countries in LATAM, the Caribbean, and Asia Pacific regions.

The performance of supply chains is driven by various stakeholders like, manufacturers, logistics service providers, and technology suppliers. The interconnectivity between these stakeholders at various levels of the supply chain includes in-sourcing, outsourcing, off-shoring, product customization, and so on. In order to move up the value chain, it is imperative that developing countries focus on acquiring state-of-the-art technologies while building human capital.

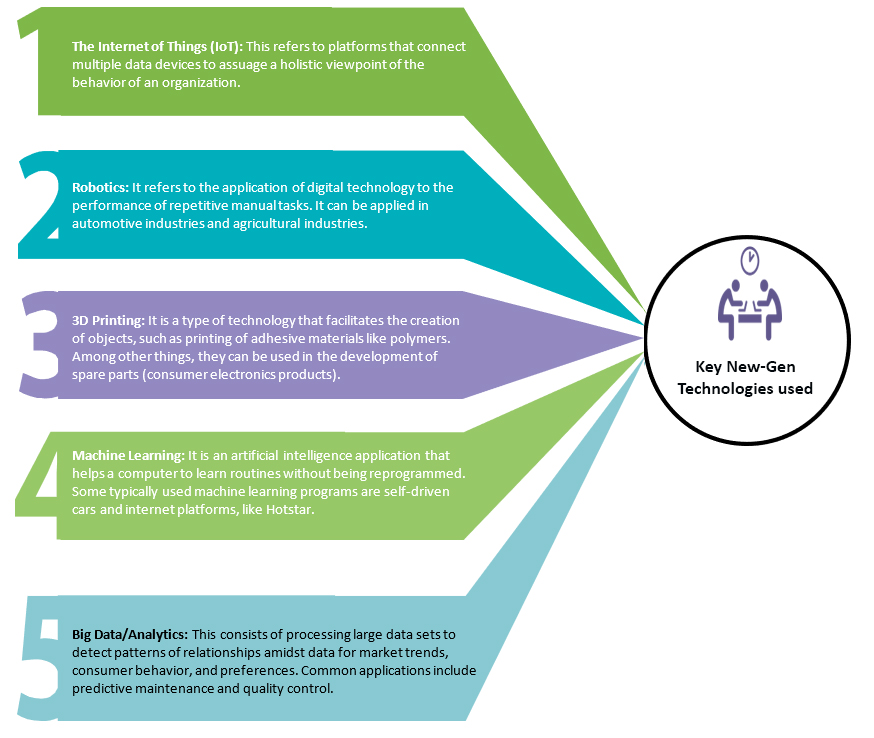

A high level of visibility is required across different levels of the supply chain for effective performance. To achieve this, an efficient mechanism that integrates coordination among the different supply chain stakeholders and accurate sharing of data across the supply chain is required. New-gen technologies, such as Internet of Things, advanced robotics, 3D printing, machine learning, and artificial intelligence can take supply chain performance, coordination, and visibility to new levels.

New Technologies in New-Gen Supply Chains

New-gen technologies can lead to enhanced visibility, better inventory control, fewer barriers, and more efficient utilization of resources. Some of these technologies are:

Barriers and Risks to Supply Chains

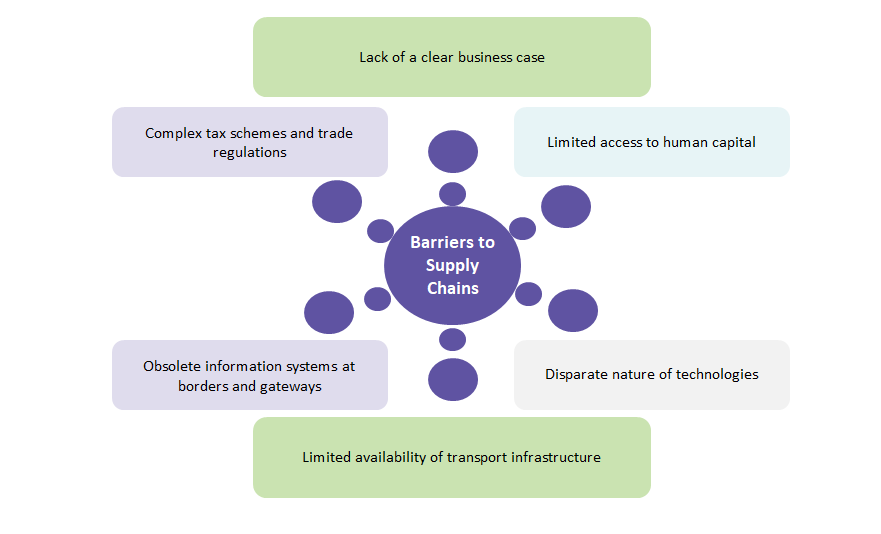

Some of the typical barriers and risks to the supply chain are:

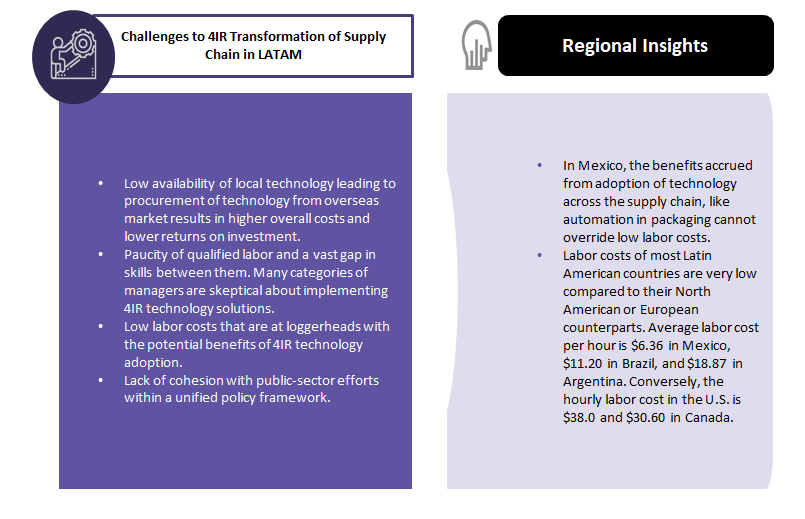

However, just digitizing the inefficient business processes will not be of any help. The internal business process has to be transformed so that it is in sync with state-of-the-art digital technologies. SMEs also face difficulties, such as limited technology availability as IT solutions focus primarily on large manufacturers’ needs, lack of adequate resources like human capital and internal resources, and inadequate finance in adopting these technologies.

Current state of supply chains in developing economies

State of Supply Chains in Latin American region

Evolution is at a rudimentary stage

-

The 4IR Transformation of the supply chain is still at a rudimentary stage in the Latin American and Caribbean regions. MNCs and large “multilatinas” have a higher level of implementation compared to the other enterprises.

-

A survey conducted by the National Confederation of Industries of Brazil in 2017 indicates a deep understanding of Industry 4.0, including the 4IR transformation of the supply chain. 4IR technologies are expected to improve relationships with suppliers using real-time monitoring of orders and logistics via web services.

Automotive supply chain leading the way

-

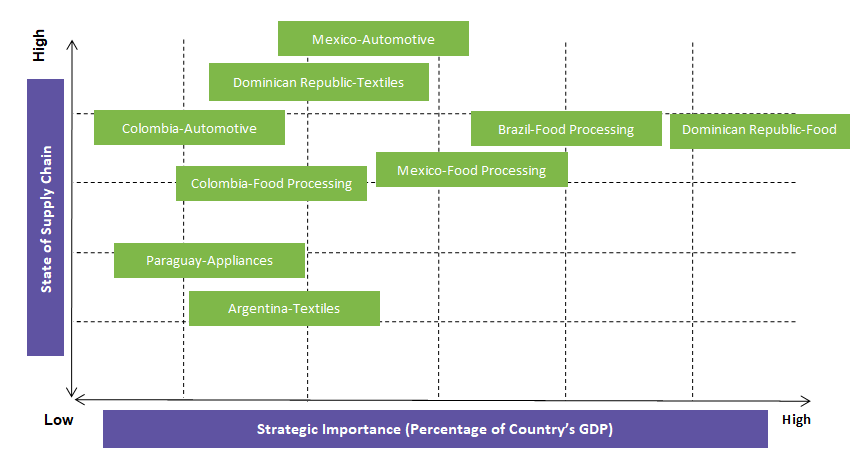

The automotive supply chain in Latin American countries is the industry leader when it comes to streamlining or transformation of supply chains. Mexico leads the way (due to its geographic proximity to the U.S. original equipment manufacturers), followed by Brazil, Argentina (low-scale implementation due to adverse economic context), and Colombia (owing to the country’s smaller market size).

-

The textile supply chain is at the bottom among all the industries in the supply chain transformation process. However, Mexico and the Dominican Republic lead owing to the economic importance of the “maquiladora” sector14 in both the countries.

Current state of supply chain in developing economies (By Industry)

Upgrading of supply chains

Developing countries perform low-value, low skilled labor-intensive tasks owing to an optimum supply of unskilled labor.

Many developed countries have a comparative advantage, which is often man-made.

For example, the UK had a comparative advantage in textile manufacturing in the post-Industrial Revolution period, which later shifted to the south of U.S. and is now possessed by China and other low-wage developing economies.

Beginning in the 1970s, several renowned firms in Japan offshored their unskilled labor-intensive manufacturing tasks to South Korea, Chinese Taipei, Hong Kong, and Singapore. Consequently, these countries entered the global supply chains by specializing in component manufacturing and product assembly. With the growth in this industrialization phase, these countries started manufacturing sophisticated intermediate units, which they earlier imported from developed countries. Later, they expanded into the distribution and design of goods, hence, upgrading their supply chain structures even more.

The rapid advancement of technology further helped many developing economies (earlier) to upgrade their supply chains. The offshoring of a firm’s technical knowhow in foreign countries through establishment of subsidiaries also helped in further upgrading supply chains. So, it can be inferred that investment in human capital and the consequent ability to integrate technology into their systems has contributed significantly towards the upgrading of supply chains of several countries.

Transfer of technology and the aforementioned processes helped developing countries, like South Korea, Hong Kong, Singapore, and Chinese Taipei upgrade their supply chains significantly. The transition of developing countries into becoming significant contributors of value-added tasks could lead to a better balance in power between the developing and developed economies.

Best practices that can be incorporated to enhance supply chains in developing economies

Learnings from other companies

- Lessons should be learned from industry leaders. First, a holistic approach to the 4IR transformation structure should be built. Second, a clear roadmap should be decided. Third, companies should not hesitate to experiment and seek joint implementation opportunities.

Overcoming region-specific barriers

- Some region-specific barriers, like low labor costs and limited availability of technology must be overcome. This can be proactively enhanced through collaboration with universities and research institutions. A prime example is the Industrial Value Chain initiative in Japan.

Lending support to the SME sector

- Many governments of developing economies are framing programs to upgrade the technology infrastructure of SMEs. For example, the digital economy projects for SMEs established by the Ministry of Industry, Commerce and SMEs of the Dominican Republic and the National Institute of Industrial Technology in Argentina. However, governments should also emphasize the deployment of technology sectors aimed at providing training for SMEs to support 4IR transformation.

Facilitating supply chain enablers

- Many governments of developing countries are trying to upgrade their transportation and gateway infrastructures and the technology capability of customs agencies. Governments could think of creating a position, like a Chief Technology Officer who will help to enhance awareness towards 4IR transformation needs.

Integration of infrastructure frameworks

- Different infrastructure frameworks need to be integrated within the broad ambit of national infrastructure. For example, Germany’s 2030 Federal Transport Infrastructure Plan and Maritime Agenda 2025 that established an integration between logistics and digitization.

Establishing a coordination mechanism

- The government, private sector, and civil society should endeavor to build a coordination mechanism to accelerate the pace of the 4IR transformation.

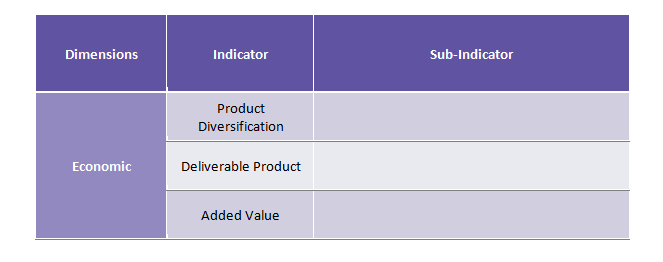

Parameters for building a Sustainability Assessment Model

Sustainability Assessment Model

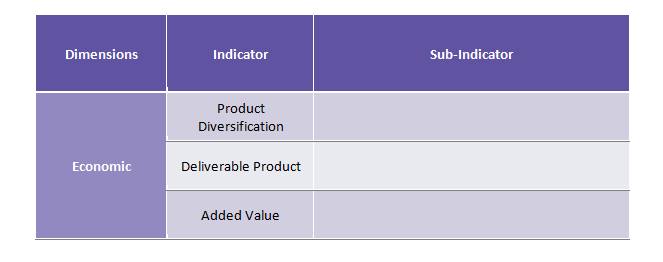

- A sustainability index can be developed from a similar one used for a manufacturing facility. The three components of the vector are: economic, environmental, and social performance of the facility.

- It is further broken down into a set of indicators and sub-indicators. All indicators and sub-indicators are dimensionless and extend from 0 to 1. The indicators and sub-indicators are added up to arrive at a single index (SI).

Conclusion

New–gen technologies, like Internet of Things, robotics, and 3D printing have gone a long way in transforming supply chains, as seen from the enhanced, streamlined, and lean supply chains in most of the developed countries. However, their adoption is still at a rudimentary stage in most of the developing nations across the LATAM and Caribbean regions. Though the supply chains of certain industries, like automotives has managed to successfully integrate the 4IR technology into its structure and transform its supply chain, other industries still lag. It is imperative that the government, private sector. and the civil society closely collaborate to develop a system that can successfully facilitate the integration of technology to upgrade their supply chains.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe