Collective intelligence enables sustainability in procurement and profitability for corporates

Abstract:

Sustainability is considered as a common goal by many major companies to ensure that they create a profitable and more sustainable environment within the limited resources available. Embedding sustainability all through the integral parts of the supply chain is considered vital for chemical industries, as compared to other industries; because the impact of chemicals on environment is high. Population growth, diminishing resources and rising consumption have been identified as critical problems which modern sustainable sourcing should tackle. This article would address key areas such as the need for sustainable sourcing and how it can be adopted by chemical companies.

What does sustainable sourcing exactly mean?

According to principles of public procurement, sustainable procurement is a purchasing and investment process that takes into account the economic, environmental and social impact of the entity’s spending. Sustainable procurement allows organizations to meet their need for goods, services, construction work and utilities in a way that achieves value for money on a whole-life basis in terms of generating benefits to the organization. Additionally, it also benefits the society and the economy, while remaining within the carrying capacity of the environment.

Need for sustainable sourcing?

With the onset of increasing global emphasis on efficient management of natural resources, maintaining a lower ecological footprint in all areas of industry has become vital. This is mainly due to the climatic changes and social problems, which we often face around the globe. The starting point to embed sustainability in whole product cycle starts with the procurement. For sustainable sourcing of materials, the future of procurement is going to focus on addressing the following:

Case: AkzoNobel

AkzoNobel focused on spending significant time and money in identifying and managing areas which will provide long-term and sustainable opportunities for the business. AkzoNobel was successful in devising the strategy, which focused on working closely with suppliers on the sustainability front enabling them to arrive at “eco-premium” solutions. Also the kind of opportunities that AkzoNobel has opened for itself has proved to be a long term resource in terms of both secured sustainable supply and innovation in their supply chain.

AkzoNobel continuously improvised the process by incorporating a strong sustainability component throughout the entire value chain, from driving R&D, identifying the market potential, improving the production process, and sales and marketing.

The economic realization of these sustainable procurement practices led to a fifth of AkzoNobel’s revenue to come from products which are more eco-efficient than the products manufactured by their rivals.

Leaner and fit sustainability models

Though the importance of sustainability is gaining visibility than ever before, the biggest question among the CPOs and category managers is how to adopt such practices without taking a hit on operating and net profit. There are different views in implementing these processes; certain organizations view it as an extra burden to their balance sheet, whereas others view it as a competitive advantage.

Sustainability may be a competitive factor or differentiator at present; however increased consumer awareness and pressure from environmental policies will make such practices mandatory within the next decade. Hence organizations which lag behind in sustainable procurement efforts may lose their shine in the coming years.

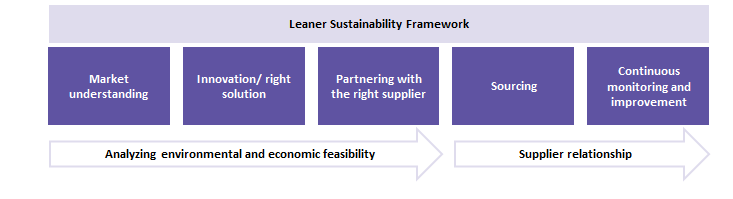

Analyzing the value chain completely and identifying the opportunities for adopting sustainable sourcing is crucial, it would help organizations in finding economical solutions. Although there are various sustainability models, leaner and simpler models are considered effective in sustainable procurement phase.

Understanding the market enables an organization to realize its potential to reap benefits at present and in the long term. Secondly, devising a right solution ensures the product and process coexist on the sustainability lines. Third phase would be identifying right suppliers and performing audits to ensure whether they adhere to the standards. These audits are generally costlier and most often organizations end up without finding right suppliers. Fourth Step would to be to enter into sourcing contracts with selected suppliers. Final stage is where the continuous monitoring and process improvement is done.

Supplier evaluation - critical piece of the puzzle

Finding a right supplier who could comply with the sustainability practices is as important as setting the policy itself. Suppliers will face the real difficulties in implementing these strategies, and it often affects the buyer in terms of inconsistent supply and increased cost of ownership. This again brings us to the importance of maintaining a leaner and fit sustainability framework.

Three qualitative factors are crucial for any buyer-supplier relationship to be successful in the chemical industry procurement.

Synergy: Choosing a supplier with same or positive caliber is vital for sustainable sourcing to be effective. This will create the right synergy between the buyer and supplier, which will help them develop the process better.

Akzonobel still retains the world leader position even after adopting sustainable sourcing, mainly because of the right synergy and transparency between Akzonobel and its supplier. Sharing of information about the process and output should be made mandatory in the contract agreement before moving ahead with the supplier.

Benchmarking: Benchmarking in terms of improvement, sustainability certifications and periodical targets should be included as key parameters in assessment of the supplier.

Geography: Most of the negative impacts and damage to society and environment happens during transit and warehousing. For example, during the Tianjin blasts in China, the impact on people and environment was severe due to the large quantities of toxic chemicals that were stored. Companies had to compromise on good will and incur more cost to repair the damage.

Process Improvement: Working closely with the supplier is as important as choosing the supplier. Assessing whether the supplier can adopt to the technical know-how, which the buyer provides, or by an external consultant.

Case: Evaluating supplier for sustainable sourcing of sodium cyanide

Sodium cyanide, a leaching element used in gold mining, is an important spend for gold mining companies. Although sodium cyanide is hazardous, it can be treated with a certain process and its dangerous impact can be nullified over a period of time. However, mercury, also hazardous, cannot be treated by any process. It was for this reason that the gold mining companies in the world decided to stop using mercury in the process of gold leaching. Now the challenge is to find a supplier who can adhere to the regulations of processing the chemical.

Let us now perform the evaluation to select a sodium cyanide supplier:

|

Capabilities of supplier, management effectiveness and ability to adopt sustainability practices |

Proximity to supply location |

Environmental and industry standards certification. In this case, the supplier should comply with international cyanide codes and should be a member of the same |

Technical know-how to dispose waste and working together. Whether waste management is in place to dispose cyanide waste. |

|

Synergy |

Geography |

Benchmarking |

Process Improvement |

Cost of implementation is generally very high in the process, which offsets the cost benefits, which could be realized by adopting sustainable sourcing. This is one of the main reasons why organizations hesitate to switch.

Cost of implementation and operating margin

From the procurement perspective, maintaining operating margins at desired levels is another key parameter which category managers are concerned about. At every level of value chain, ensuring that the cost optimization is done is the key in maintaining overall operating margin.

For example, BASF analyzed their chemical supply chain and categorized it into four segments. These four segments are divided based on aspects such as difficulty in implementation and feasibility in implementing sustainable sourcing without affecting the operating margin. This classification provides companies a clear focus on feasible things on which they can invest and reap the benefits. The companies can also use expertise for the more challenging categories. Thus, achieving material cost savings cannot be done with one-shot strategy. It needs multiple strategies for working with suppliers to identify areas which can be optimized; the actual benefits will eventually follow.

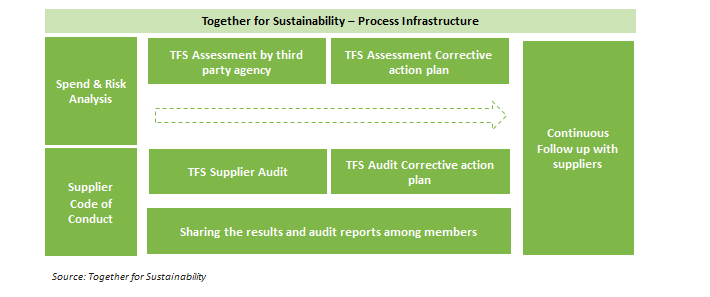

Collective intelligence approach to optimize adoption

Collective intelligence towards sustainability has already started to prove beneficial with the initiative, “Together for Sustainability”(TFS). CPOs of six global chemical majors -- BASF, Bayer, Evonik, Henkel, Solvay and Lanxess -- formed the initiative to understand the impact that chemical supply chains bring on to the environment. The objective of TFS is to bring in transparency in sustainable practices, and perform supplier and regional sustainability audits together. This is to reduce the cost of adopting sustainability and continuously architect a solution which is cost effective.

TFS embarks on the need to incorporate sustainability in procurement evaluation. As a result of its resounding success, many more chemical giants such as Akzonobel, Arkema, Clariant, Covesto, DSM, Eastman, IFF, Merck, Syngenta and Wacker became members of TFS.

Chemical majors joining hands to reduce the cost involved and devising practical action plans is a healthy sign in the industry. A chemical company, which wants to follow sustainable practices, can join initiatives such as TFS on an annual fee basis. Also, chemical producers can jointly conduct sustainability audits.

Collective approach becomes beneficial and economical when companies need to perform supplier evaluation in highly segmented markets such as China, LATAM and other emerging economies. Suppliers in these regions generally lack the expertise to execute sustainable practices. However, they still have the potential to serve as a best-cost sustainable supply partner.

Hence, integrating sustainability in procurement strategy has become equally important as the profit itself. Setting sourcing strategies specifically to each category and spend pool with focus on use of sustainability certified raw materials would be the first step at the sourcing level. Sharing the cost incurred as per region or industry, consolidating volumes and maintaining transparency in sharing the knowledge could be the possible future of sustainable sourcing.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe