Supply Chain Restructuring in Reality

Times have changed and so has the supply chain. With the onset of COVID-19 and other macroeconomic factors, the pressure on the supply chain is greater than ever before. In these testing times, a major aspect that is being considered is supply chain restructuring. Rising freight costs, port congestions, container shortages, inflation, and other factors have forced most industries to revisit their supply chains and restructure them if required. In this regard, 2022 has become a pivotal year in which most companies have turned their focus to reliable means of procurement.

Globally, most manufacturers have reviewed China Plus One sourcing as a business strategy. In this article, we will discuss how efficient this strategy is and its limitations. Many manufacturers, having actively engaged with China for several years, may be at a critical juncture to reevaluate their supply chain and make the changes necessary to sustain in the market.

Many companies consider the current crisis as an opportunity to make their supply chains more reliable and resilient. They are prioritizing social and environmental performance during supplier engagement and supplier capacity building. In reality, the buyer–supplier relationship has changed, and it is crucial for them to work together and advance at scale and speed to achieve sustainable solutions and meet all targets in real time.

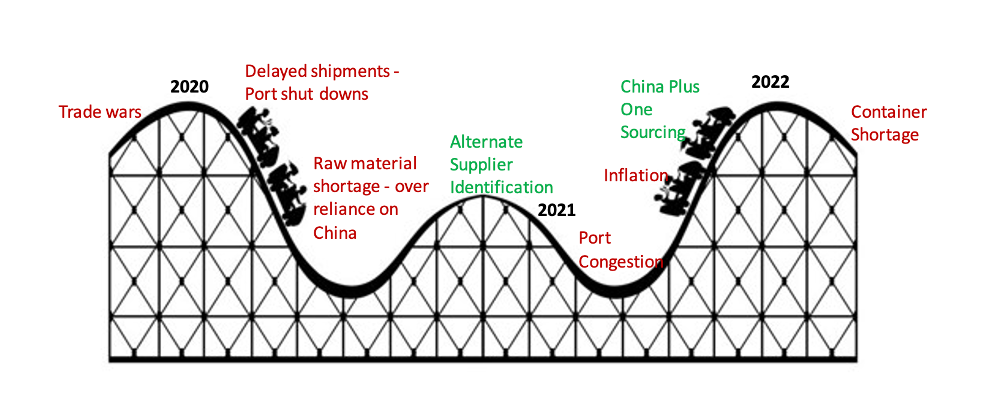

Supply Chain Roller Coaster

In recent decades, major advances have been made in fields such as technology and transportation. However, these advancements could not prevent the disruptions that occurred in supply chains between 2020 and 2022. The impact of trade wars and COVID-19 have triggered a series of events that are illustrated in the figure below. For supply chain professionals, the period was a roller coaster ride, as they were constantly faced with highs and lows in the market. Working with utmost caution was still not helpful as there was limited data beyond supplier or their supplier. Choke points could occur at any point in the supply chain.

From sourcing raw material to transporting finished products, balancing the risk and knowing where major risks lie is crucial in efficiently managing the supply chain.

China Plus One Strategy

China has been the manufacturing hub mainly due to low-cost labor. However, due to the current risk of supply assurance, companies are forced to look for alternative locations to China. However, this does not imply that they will cease operations in China entirely. The China Plus One approach has become popular among companies looking for another low-cost source as a backup. Other Southeast Asian countries, such as Vietnam, the Philippines, Thailand, and Singapore are under consideration as prime candidates for manufacturing. Here, we discuss the feasibility of various aspects of the China Plus One strategy adoption.

|

Feasible |

Not Feasible |

|

Moving to a network of trusted suppliers outside China will limit supply chain complications |

Moving all operations out of China is not feasible. The majority of operations may still continue to be in China |

|

May not be a victim of trade wars between China and the developed countries |

Certain raw material such as chemicals and active pharmaceutical ingredients cannot not be procured in large volumes from any country except China |

|

Near-shoring or reshoring can be an option when moving out of China |

Moving entire facilities to developed countries like the U.S. and Europe requires huge capital and long-term expenditure may also be high |

|

Overcome the effects of rising labor wages in China to some extent |

Finding low cost labor elsewhere is not possible. Although China has increased labor wages it is still on the lower side compared to wages in developed regions |

The China Plus One strategy is dependent on several factors, including identifying a country with adequately stable infrastructure and social and political environment, such as India, Vietnam, and Malaysia. It is a strategy that is expected to be in place for several years and may be a starting point for companies to build a more resilient supply chain.

Conclusion

In a globalized marketplace, focusing on reliability and sustainability is essential. Although this might come with higher rates, these factors must be incorporated for smooth functioning of business, especially during times of disruption.

-

Manufacturing should be distributed such that a company is not reliant on any one country for its products and can shift production should unexpected political, regulatory, weather, epidemic/pandemic, or other events occur in a particular region.

-

Apart from the supply chain constraints such as longer lead times and container shortages. China’s increasing labor cost, political tension, and aging workforce may be some of the other reasons to look for an alternative sourcing location.

-

Supply chain restructuring in reality is a tedious task which involves large amounts of data gathering, several important decisions, and expenditure in the millions. Therefore, it is wise to spend more time analyzing and implementing the right strategy that fits your business.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe