Effective governance structure can help foresee conflicts in buyer-supplier relationship

In collaboration with Rajeev Velusamy – Senior Research Analyst

In recent times, there were few notable disputes between buyers and suppliers:

1. An interiors supplier of General Motors filed for chapter 11 bankruptcy protection early in July, a move that had briefly threatened to shut down 19 GM assembly plants in North America. This issue was later resolved.

2. Volkswagen and two of its parts suppliers resolved a contract dispute that had hit output at more than half of the carmaker's German plants. Faced with billions of euros of costs from its emissions scandal, the company had previously indicated it would seek price cuts from its suppliers.

3. U.S. retail firm Target said it will end its business relationship with Welspun India, one of the world’s biggest textile manufacturers, after saying the supplier was sending low-quality bedsheets as premium Egyptian cotton. News reports have suggested that even Wal-Mart is evaluating its relationship with Welspun.

Such supply chain disruptions are not uncommon. In fact, as per a recent survey conducted by Zurich Re and Business Continuity Institute (BCI), almost three-quarters of respondents have reported at least one instance of supply chain disruption in the last 12 months.

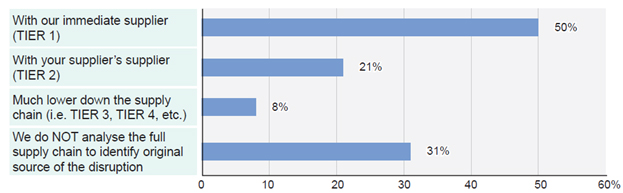

The survey also revealed lack of supply chain visibility with 31 percent not analyzing their supply chains at all:

Source: Zurich Re and BCI -- Supply Chain Resilience Report 2015

As per a global research study on supplier risk management, most of the organizations lack an effective governance structure in place. More than 65 percent of the participants mentioned that they have a formal methodology or framework to drive supplier risk management but it is not effective enough to offset supply chain risks.

An effective governance structure can help foresee supplier problems in advance; and a governance program must consider all possibilities of supply disruption, and have a formal structure in place with process owners to mitigate risks. This ensures quick recovery from the disruption and minimizes the impact.

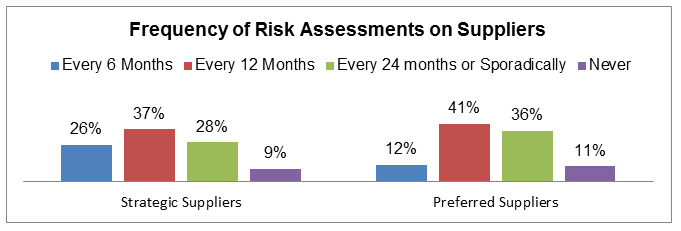

Based on the study done by APQC, below is the brief of how frequently organizations assess their strategic and preferred suppliers:

The study reveals that organizations are able to offset supply chain disruptions by frequently carrying out risk assessments on strategic and preferred suppliers.

In other words, a governance structure along with periodic risk assessments will act as an early warning system in predicting future issues.

As we have noted in our previous blog post, it is tough for procurement organizations to proactively prevent every incident of supply disruption. However, it will help if an effective governance structure is put in place.

Some of the best practices on effective governance structure are:

- Assigning functional head and process owners at regional level

- Review meeting at least twice a year to discuss the status of assigned tasks

- Review meeting at least twice a year to discuss about potential risks

- Clear escalation procedures to manage and resolve conflicts

- Periodic training and drills for employees involved in risk management process

- Frequent assessment of supplier performance and re-examining supplier segmentation on a constant basis

|

Benefits |

Challenges |

|

Multi-tier Supplier Transparency

|

|

|

Need for data assimilation and analysis

|

|

|

Tracking supply chain risk rigorously

|

|

|

Effective Governance Structure

|

|

Governance framework has to be well-defined to facilitate flow of communication between suppliers and procurement teams.

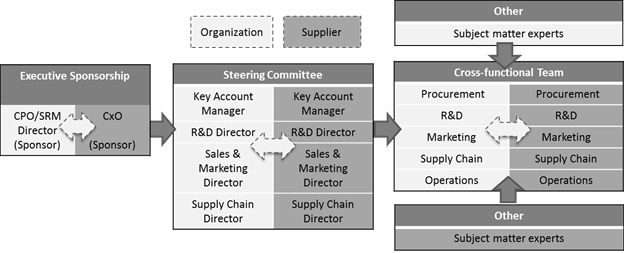

A governance structure needs to have the following elements:

- Dedicated steering committee, executive sponsors and stakeholders from both business division and supplier

- Description of roles and responsibilities along with the reporting structure in the organizational chart

- Indication of required FTE

Finally, a flexible joint balanced scorecard that includes KPIs for both supplier as well as organizational performance is needed to effectively measure the progress of SRM program.

Stakeholders, cross-functional teams and supplier representatives should be trained on evaluating performances in order to avoid errors in the assessment.

Also, KPIs included in the balanced scorecard has to be both qualitative and quantitative such as cost, quality, delivery, support and so on.

As we have said in our previous post, business relationship between buyers and suppliers will occasionally break down. However, the key lies in foreseeing such breakdowns in advance so as to prevent major disruptions.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe