Adopting construction equipment telematics enables effective asset utilization

Abstract

Despite the introduction of telematics in 2000, its concept and implied benefits were relatively less familiar among construction equipment fleets, with market penetration at less than 30 percent in 2016. Despite low penetration, the North American construction equipment telematics has proved successful and efficient in improving productivity and reduced operating costs for construction equipment users.

The construction equipment market is composed of numerous fleet operators. Despite their awareness on telematics, they are reluctant to integrate the technology into their business processes because of the complex features, high price points, and non-user-friendliness. Thus, considering the budgetary concerns of the customers, vendors can address this market challenge and offer an affordable telematics system, with the best return on investment (ROI). This in turn enhances customer value, induces competition and allows construction firms to cut operating costs.

This article highlights how equipment manufacturers, operators can make over their businesses and stand out from their rivals by sensibly adopting telematics and other disruptive technologies.

Introduction

Telematics systems merge GPS technology, on-board diagnostics and sensors to monitor, maintain a record and report data via cellular networks on the performance of construction equipment.

Construction telematics outlook

In recent years, the construction industry has been among the most passionate adopters of innovative technology. This is partially due to the 2008 economic crisis when construction firms were under pressure to adjust to the changing economic situation by improving their efficiency. GPS telematics systems provide appropriate data on the condition, performance and position of assets in the field. Telematics in the building industry falls into two categories – on-road and off-road; the benefits the technology provides vary drastically between the two categories.

On-road construction telematics

The construction industry makes ample use of on-road vehicles, and GPS telematics has been broadly adopted for use with these fleets. However, the use of on-road construction telematics systems can be broken down into two sub-categories – the movement of people and the movement of materials. This ensures human resources are in the correct place at exact time, so that team members are in place to finish the work when it needs to be completed. Site reporting is a key attribute offered by telematics, by providing managers up to date information with which members of the team are on site. By facilitating the movement of materials, telematics makes it easier for construction teams to progress according to their designed schedule. Further improvement to competence is facilitated by an improved route plan and fuel expenses.

Off-road construction telematics

Telematics is also used to track the site and performance of plant equipment for utilization and maintenance. Hence, this helps construction firms to slice hire costs. Off- road construction telematics track hours of use, location of equipment, and also report on whether that equipment is being utilized across various sites.

Demand for construction telematics

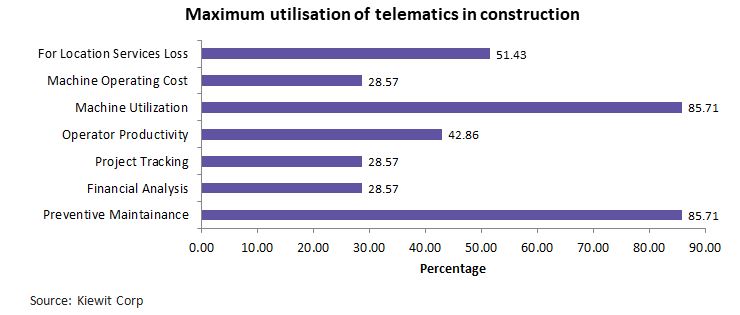

Integration of telematics devices in vehicles, with standardization and addition of telematics data across various business functions creates a transformation in the field of construction equipment telematics. Perhaps more than any other business, the construction industry is set to harvest benefits of the seismic shift taking place in construction equipment telematics. Construction equipment presently accounts for 62.4 percent of the market share of OHVs, a market that furthermore included farming and mining vehicles in 2016. Adoption of telematics in the building industry is advanced due to pent up demand from construction equipment rental companies. Preventive Maintenance and Machine Utilization account for 85 percent of the major use in the construction industry.

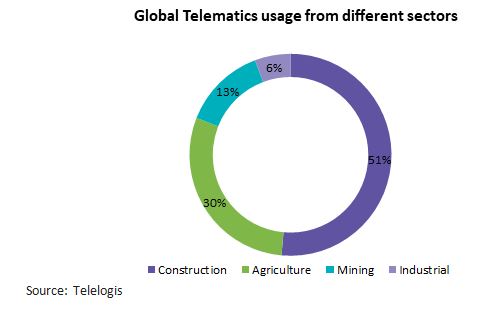

The construction and industrial segments held the major market shares in the off-highway vehicle (OHV) telematics market in 2016. Demand from the construction and industrial segments will continue to rise significantly, with the construction equipment rental market expected to grow from 13 to 15 percent over the next five years.

Construction dominates off-highway vehicles telematics market. Growth of the worldwide OHV telematics market is primarily driven by increasing adoption of telematics technologies across all industries such as construction, agriculture and mining equipment.

Impact of construction telematics on contractors

To achieve better equipment fleets and cut overheads, contractors are progressively using telematics technology, which blends on-board instrumentation and Internet computing. The downturn has forced firms to do more with less, driving innovation to remain competitive. Telematics has become a digital-age toolbox for succeeding in today's tight economy.

Utilizing the equipment right: When requests come in for more trucks on a particular project, there is no need for engaging too many trucks on the same project. Impact: Construction telematics paves way to identify the utilization of the equipment and find ways to reuse the equipment effectively without affecting the schedule.

Reduce fuel consumption: Fuel is the second largest cost for a construction fleet. Since vehicles make regular trips back and forth, the fuel is burned inefficiently. Impact: Telematics enables construction managers to track the vehicular movement and understand where idling happens so that they can take corrective measures to improve efficiency.

Save on Capex: Contractors can sell or add value to their old equipment as technology meets innovation. Impact: Contractors can get the best resale value for their used vehicles by providing their maintenance history through widespread automated record via telematics solution.

Boost security and eliminate theft: Unauthorized use of equipment can cause damage and loss. Impact: Telematics supports in tracking the location of an asset – even when the equipment is turned off. Impact: Geofences can be established to receive alerts in case of any movement of the asset beyond its perimeter such as a job site.

Conclusion

With adoption rates still comparatively less, contractors now take the initiative to stay ahead of the competition to enjoy a wealth of benefits and cost savings which will permit them to run their business better and smarter. Sustained investment in technologies that decrease downtime, facilitate planning and drive up competence will therefore be crucial to the construction industry. This is why construction telematics is likely to play a progressively significant role in the building industry over the next few years. Telematics help contractors understand the actual equipment repair costs and also makes it easier for them to invest in the upkeep of their machineries.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe