Technology Trends in Pharmaceutical Manufacturing

As pharma companies are moving more towards digitization and innovation to optimize the supply chain, there has been advancement in drug product manufacturing. The aim of this article is to have a summary on technology trends and how it’s impacting the overall industry. The below mentioned drug development and formulation technologies are currently growing at high growth rate aiming to improve the patient adherence. External manufacturers have been investing in these areas to improve on the capacity and lead time. Pharma companies are favoring those CMOs who have the CM equipment (continuous flow reactor etc.), facilities and labor force for cost effective drugs manufacturing,

- Continuos Manufacturing Technology

Continuous manufacturing is still a new technology in pharmaceutical industry. This is due to the increasing demand for complex and innovative therapies and rising competition among big pharma companies to ensure cost savings and fast approval of drugs. Continuous manufacturing of pharmaceutical finished products is in commercial operations and there have been small molecule products approved in the US and Europe. In APAC, it is still a nascent stage and very few suppliers are currently using this method.

US and Europe contribute to 80% of suppliers in terms of count. APAC does not have many suppliers in continuous manufacturing. Recently many companies have done investments in order to install this technology and expand their capacity and capabilities

Some of the major potential advantages:

- Lower cost

-

Reduced labor

-

Reduced waste

-

Shorter development times

-

Reduced utilities costs

CM facility is 70% smaller than the batch production facility. The reduced size of equipment

-

Increased quality

-

Reduced scale-up issues

-

Flexibility of batch size

-

Smaller product footprint

-

More efficient use of equipment

-

Possibility of real-time release, assuming adequate process controls are in place

-

Less product at risk at any one time

-

Ease of automation

-

Enclosed process

- Reduced operator exposure

Disadvantages include

- More difficult changeover between products

-

Smaller equipment which may need to be disassembled for cleaning

-

One CM line may only be suitable for a restricted number of products

-

Capital investment required

-

Source: Expert inputs

More than 60% companies are offering this technology for API. However, for drug product number of companies are low.

Overall, with the integration of CM, 70% of highest volume products using CM within eight years, increase the yield by 33% by reducing waste and reduce the manufacturing and testing cycle time.

2. Artificial Intelligence

AI is being used for drug discovery and aid the process of molecule synthesizing. Currently, this technology is being leveraged by many big pharma companies.

Example: Exscientia AI, a leader in AI-powered drug development helps in the drug development for CNS treatment. It claims that AI-based process can reduce the time spent in drug discovery from 4.5 years to as little as 12 months, and reduces discovery costs by 80%.

Examples of AI Companies partnered with big pharma companies

|

Pfizer |

AZ |

Novartis |

Bayer |

GSK |

|

Insilico Medicine |

Berg |

Microsoft |

Exscientia |

Exscientia |

|

Atomwise |

Benevolent AI |

Dyno |

Cyclica |

InveniAI |

|

Cytoreason |

Deepmatter |

Mila |

Atomwise |

Cloud Pharmaceuticals |

|

IBM Watson |

Eko |

Intel |

Genpact |

Insilico Medicine |

|

Concerto |

Microsoft |

IBM |

Sensyne Health |

|

|

Complexica |

Tencent |

Tencent |

|

|

|

Sidekick |

RenalytixAI |

Benevolent AI |

|

Source: Netscribes.com

Apart from the above major AI suppliers, there are many start-ups in this space. AI space market is fragment one if startups are being considered. Medical imaging & Diagnostics is one of the AI-powered solutions which is highly fragmented and matured classifications with many start-ups. Most of these companies use deep learning techniques to analyse the data extracted from radiology images.USA (51%) dominates globally in terms of number of AI Start-ups followed by Europe (33%) and Asia. Drug discovery and development attracts more funding from investors.

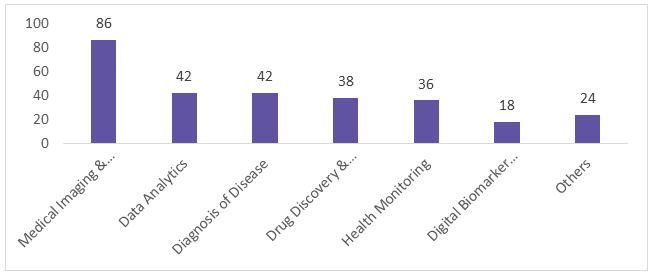

Below is the snapshot of number of AI based start up companies in different segments of health care.

Source: Beroe Analysis

3. Automation & Digitization

AI and smart technology provide end-to-end product visibility (eg.track and trace) in the supply chain. Automation helps in reducing costs, and providing strong and cost-effective supply chains.

Big pharma companies are joining each other for the use of smart technology in the supply chain. Real time supply chain monitoring, stock in levels, inventory and logistics are some of the advantages of automation.

Example: Pfizer is using a form of automation known as Flexible API Supply Technologies (FAST) to develop its active pharmaceutical ingredients (APIs). It has helped reduce the production-to-market timeline.

In addition to automation, big pharma companies have begun digital transformation ranging from R&D efforts to next-generation customer interaction. Companies like Pfizer, Novartis, Sanofi have already been taking steps in terms of digitial innovation. This is also aiding them in curbing clinical trial data privacy issues, and also take a stand against counterfeit drugs (block chain technology). According to study by PwC, through digitization, downtime in pharma plants can be reduced by 30-40%. 3D printing can make a decentralized production coat efficient even at low volumes.

With the support of digitization, CMOs are able to do remote tracing of production and delivery to increase the visibility in the production process.

Conclusion

Big pharma companies and large CMOs to gain competitive advantages are adopting these trends in their supply chain, though its complex task involving risk factors. Two major trends can be concluded as artificial intelligence and use of continuous technology in drug manufacturing. Despite the challenges associated with the adoption of new technologies, market growth rate is expected to be more than 20%. Suppliers will slowly move toward these technologies to over exceed the expectations of their client.

References

https://www.netscribes.com/pharma-trends-2021/

https://www.rootsanalysis.com/reports/view_document/continuous-manufacturing/308.html

https://www.pharmexec.com/view/technology-driving-the-pharma-industry-in-more-ways-than-you-think

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe