Opportunities and Challenges in Sourcing Molds for Packaging Plastics

Abstract

Rigid packaging products such as caps and bottles are manufactured using injection and blow mold technologies, respectively. Mold sourcing is a complicated process since it is a one-time decision in the lifespan of a mold. Improper mold sourcing and maintenance strategy could lead to losses when the mold fails to last. Both injection and blow molds are classified as Tier 1, Tier 2, and Tier 3 based on cavity and complexity of the mold. The right sourcing option for the right mold tier optimizes mold sourcing and provides cost-saving without compromising on quality. The ideal mold sourcing option also helps to optimize mold maintenance cost involved. This article intends to address the various sourcing strategies available for sourcing low-cost injection and blow molds, for caps and bottles in Europe, along with precautionary measures to be taken for low-cost mold sourcing.

Mold Market Overview

The market for injection and blow molds for caps and bottles was valued at $41 billion in 2017. Europe is the supply hub for technologically advanced molds. The use of high-end technology tends to increase the mold quality and also its price. The mold market in Europe is fragmented by the presence of global and regional players. The strategic sourcing of molds in the region can provide buyers quality molds for reduced prices.

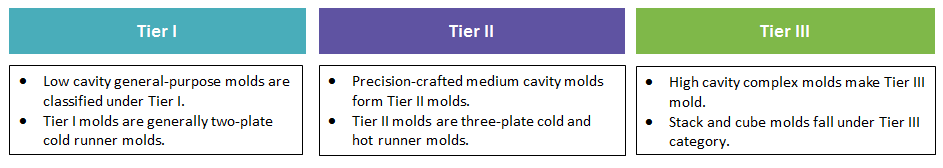

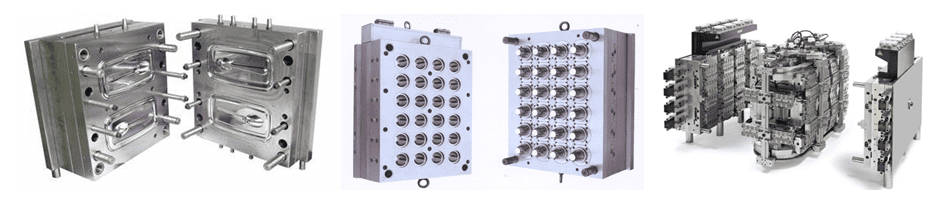

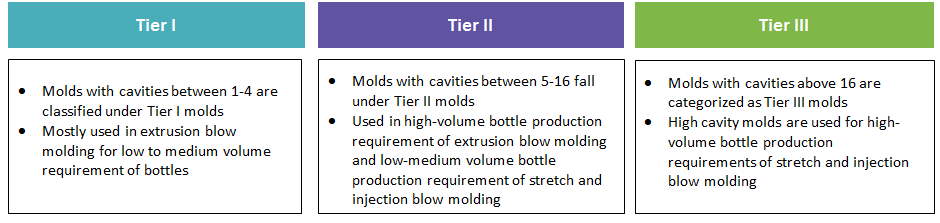

Blow molds are generally classified into three tiers based on the cavity and complexity of the mold. The different mold tiers and its low sourcing strategies are addressed further in this article.

Injection Mold Types

Blow Mold Types

Choice of Mold Material

The choice of mold material depends upon the complexity of mold design, number of cavities, and the required lifespan of the mold. Generally, molds are made of high-grade steel and aluminum. Molds made of high-grade steel tend to last longer than aluminum ones.

Low-Cost Sourcing Strategies of Injection Molds

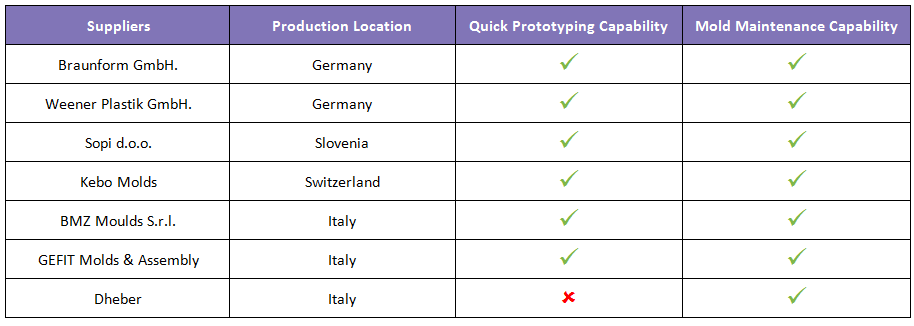

Strategy 1: Sourcing of Tier I and Tier II Injection Molds from Regional Suppliers

European regional players from Germany and Italy are equipped with the technologies capable of manufacturing Type I and Type II injection molds. This avoids the dependence of the buyer on a single/global supplier for sourcing Tier I and Tier II molds.

Engaging with regional suppliers for low-cavity molds provides the buyer with higher negotiation power and lowers cost. Regional suppliers are also capable of providing quick prototyping of molds and engage in mold maintenance services.

Some of the potential European regional suppliers capable of producing Tier I and Tier II injection molds are as follows.

Strategy 2: Sourcing of Tier III Injection molds via Central Sourcing

- High-cavity complex molds are generally sourced from global players, who tend to have higher negotiation power considering the supply tightness in high-grade steel— the raw material of major molds.

- A few of the European buyers have executed central sourcing of Tier III molds from large mold manufacturers to decrease the high supplier power. Brands, such as Reckitt Benckiser, Unilever, etc., centrally source a major portion their Type III mold requirements from large global manufacturers, such as Husky, Plastisud, Zahoransky, etc.

- Central sourcing not only provides increased buyer power, but also blanket maintenance contracts that could help control maintenance costs, provide better warranty coverage, reduce mold downtime, and improve spare parts availability. Central sourcing of injection molds can be adopted by other European buyers to take advantage of central sourcing.

Strategy 3: Sourcing Injection Mold from Integrated Converters

- The first two strategies will help in direct sourcing of molds from mold manufacturers. There is an alternate way of sourcing molds from suppliers whose core business is not mold manufacturing.

- Global caps and bottle manufacturer Weener Plastiks, headquartered in the Netherlands, is backward-integrated to mold manufacturing. UK headquartered Global Closure Systems, the manufacturer of caps and closures, also manufactures caps and closures molds. There are a few other integrated converters who are involved in mold manufacturing.

- Sourcing of molds from integrated converters will help buyers to avoid the upfront mold cost, which gets absorbed into the product price. The mold maintenance cost can also be shifted to the product price on request.

Strategy 4: Sourcing Blow Mold from Mold Manufacturers with Additional Plants in Low-cost Countries

- European mold manufacturers, such as Foboha, Zahoransky, Ermo group, Bericap, Pernoud Moulds, S.r.o, Agilys Industrial holdings have additional production plants in low-cost countries like China, India, etc. Engaging with these suppliers will help buyers to take advantage of low-cost labor and other production features of the region into the mold cost.

Low Cost Sourcing Strategies of Blow Molds:

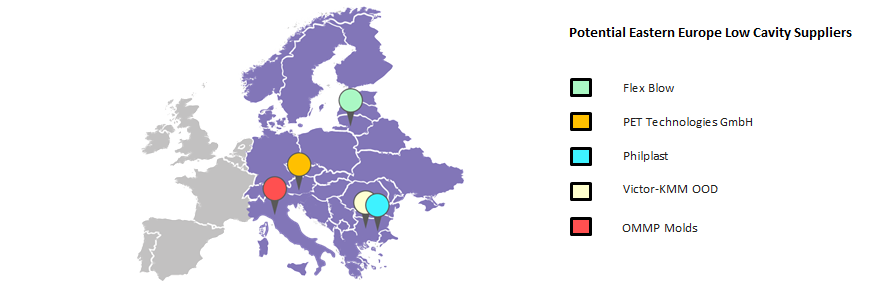

Strategy 1: Sourcing of Low Cavity Blow Molds from Eastern Europe Suppliers

Low cavity molds are mostly used in the extrusion blow molding process. Manufacturing of blow mold is less complicated than injection mold. This makes the cost of blow mold nearly three times lower than that of injection mold. Hence, the suppliers from Eastern Europe are equipped with low cavity blow manufacturing technology.

Sourcing low cavity molds from the Eastern Europe suppliers would give buyers the opportunity to take advantage of the low labor cost in the Eastern Europe Countries. Eastern Europe suppliers, on average, are capable of producing 20-40 molds per annum, hence, sourcing molds from low-volume suppliers of Eastern Europe, bestows buyers with higher buyer power achieved through high volume purchase.

Strategy 2: Combined Sourcing of High Cavity Blow Molds from Large Suppliers

- High cavity blow molds are used in stretch and injection blow molding processes. High-cavity blow molds are generally sourced from large suppliers equipped with the technologies to produce molds for stretch and injection blow molding. Large buyers can combine their mold requirements across different production locations and source it from a few global players.

- Combined sourcing of blow molds leads to greater volume of purchases. The increased volume purchases can lead to high buyer power and blanket maintenance contracts through central sourcing of injection molds.

Strategy 3: Sourcing Injection Mold from Integrated Converters

- Blow molds can also be sourced from integrated bottle converters like sourcing injection molds from integrated caps and closure converters.

- Sourcing blow molds from integrated converters will provide buyers with similar advantage like that of injection mold sourcing from integrated converters—avoidance of upfront mold sourcing cost, which gets absorbed into the product price along with the mold maintenance cost.

Strategy 4: Sourcing Blow Mold from Mold Manufacturers with Additional Plants in Low-cost Countries

- Sourcing blow molds from suppliers with additional production facilities in low-cost countries of Eastern Europe, China, India, and other countries will provide buyers with quality molds.

- Low production cost of the mold in low-cost region also gets transferred to the buyer as reduced mold prices.

|

Conclusion

Choice low-cost mold sourcing strategy depends on the end use requirement of the mold. The execution of low-cost sourcing strategy according to the mold tier type will provide buyers with increased buyer power and provide blanket maintenance contracts that will help the mold to last longer.

The use of proper mold maintenance cycle can also make the mold last longer. Mold maintenance cycle industry norms are mentioned as follows.

|

Mold Type |

Injection Mold |

Blow Mold |

|

Tier I |

< 100,000 runs |

60,000 – 80,000 runs |

|

Tier II |

500,000 – 1,000,000 runs |

300,000 – 500,000 runs |

|

Tier III |

>1,000,000 runs |

> 500,000 runs |

Implementation of low-cost mold sourcing strategy, along with precautionary steps and practice of mold maintenance cycle in accordance with industry norms will provide buyers with low-cost quality molds that last longer than expected.

References

https://www.unitedgs.com/resources/five-things-know-your-next-injection-mold/

Recommended Reads:

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe