Changing Scenario in Customization Fulfillment and Copackaging Industry—How Brand Owners Should Plan Their Future Strategy

Abstract

Introduction

In today’s competitive consumer market, every brand owner focuses on efficiency and effectiveness. Therefore, ‘contract packaging’ is inevitably one of the most discussed options. Why is this so? This is because from cost savings on equipment and facilities to marketing specialty customization and packaging, contract packaging can cost less and deliver more in many businesses.

Today’s global Fortune 500 companies are moving towards automation because they foresee a major increase in labor costs due to labor shortage and lack of technical expertise. This trend will have an impact on brand owners in terms of strategies, engagement, and pricing models adopted with their copacking and customization fulfillment vendors.

Contract Packaging Value Chain

|

Level of Integration |

Value Added Service |

Source: Supplier interaction.

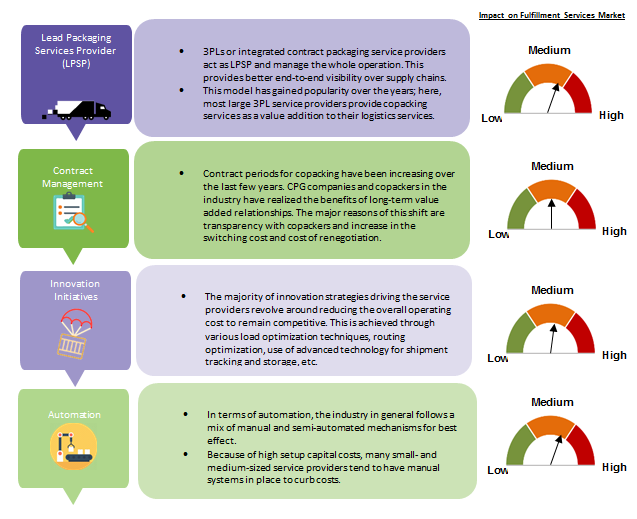

Trends Observed in Copackaging

Increasing switching costs and complexity in copacking processes have led to brand owners seeking long-term relationships with their suppliers. This would aid brand owners in implementing sustainability initiatives in their operations.

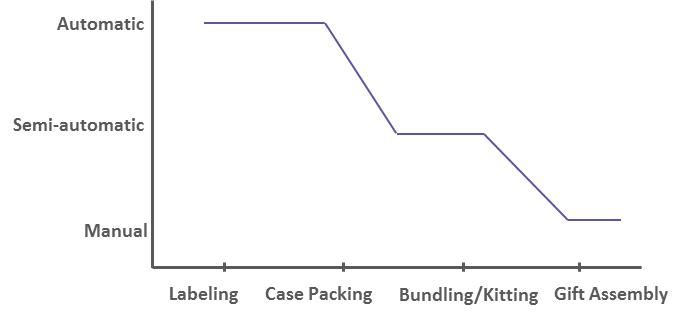

Automation Trends Driving the Copackaging Industry

Most of the copacking lines employ semiautomatic mechanisms. Collaborative robots have started gaining importance and are performing copacking operations alongside human workers.

Current Automation Levels—Contract Packing

Source: Supplier interaction, American Pharmaceutical Review, DHL, Beroe Analysis.

|

Supplier |

Technology |

Description |

Image |

|

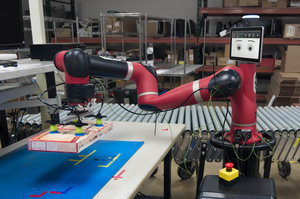

DHL |

Warehouse robots |

DHL is currently testing two collaborative robots (Baxter and Sawyer) in its warehouses to perform copacking and value-added tasks, including assembly, kitting, packaging, and pre-retail services. |

|

|

The adoption levels are low to medium as far as the collaborative robots are concerned. Small suppliers might find it challenging to use this technology owing to the higher costs involved. |

|

'Collaborative robots have enabled us to improve the layout and flow of each packing task, increasing the amount that colleagues can process. In some cases the integration of robots into our production lines has increased productivity by up to 15 percent, meaning we can manage more for our customers in a shorter time period.’ Simon Woodward, Director of copacking and production logistics |

Source: Supplier interaction, American Pharmaceutical Review, DHL, Beroe

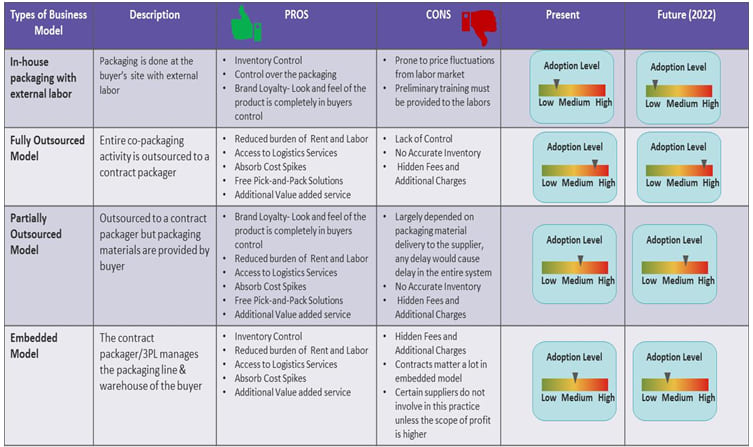

Business Engagement Models and Adoption Trends

Source: Beroe Analysis, Fulfillment Companies

Outsourcing Strategy

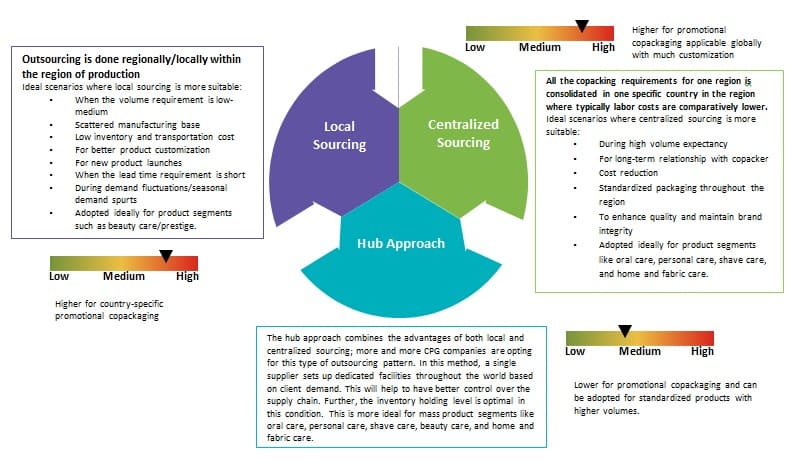

The adoption rate varies according to the buyer’s order requirement and scope of the market. For country-specific promotional copackaging, local sourcing is the preferable model adopted by buyers. For promotional copackaging at the global level with higher volumes, a centralized approach is preferable.

Major Industry Best Practices—Copackaging

Payment Models to Consider

|

Pricing Models |

Price Component |

Adoption Rates |

Customization Complexity |

Impact on Service Delivery |

|

Cost-plus/Open Book Pricing |

Direct + indirect + fixed costs + mutually agreed margin

|

High during seasonal promotional copackaging activities |

Medium to high |

|

|

Fixed Price/ |

Fixed fee (flat fee per unit of work including supplier margin)

|

High for standard copackaging products

|

Low/Standard |

|

Conclusion

Brand owners can focus on engaging highly integrated suppliers and the use of automation in the copacking process. This will help in reducing the overall cost.

To look out for—Labor constitutes a major portion of fulfillment services costs. Any change in the labor market will have a direct impact on this cost. This dependency on labor has to be reduced. This is a major reason for the increased demand and investment for new automation in fulfillment services. Therefore, brand owners should keep tabs on upcoming automation technologies and implement them on the basis of feasibility and requirement.

In Terms of Sourcing:

- Local Sourcing—This is suitable for brand owners with regular and specific packaging requirements. It will enable them to have better control over factors such as customization and lead time.

- Global Sourcing—This is suitable for higher volumes destined for global locations with no much customization.

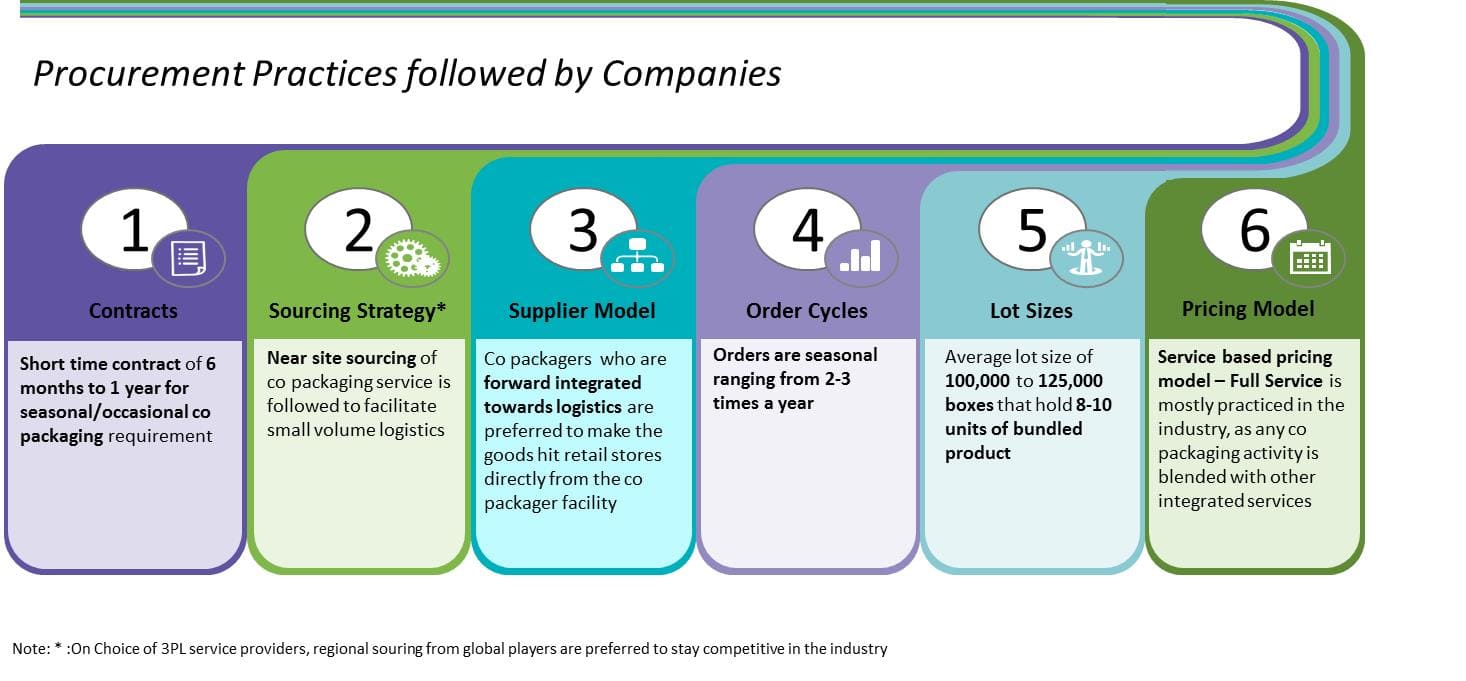

Now, in terms of engaging suppliers, brand owners can adopt a fully outsourced model; that is, they can engage a contract packager with forward integration to logistics. Integrating secondary packaging with distribution can reduce the combined warehousing, packaging, and freight costs by approx. 30 percent.

Lastly, not to forget the payment models currently in use, brand owners can opt for the cost-plus model for promotional packaging when customization is fluctuating and does not follow a standard pattern. The fixed price model can be adopted when customization is standardized and required throughout the year.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe