Growth Opportunities and Implications of Robotics in Construction

Abstract

Robotics used in building construction sites can reduce construction time and increase safety by replacing humans in dangerous operations. Construction robots are well-defined as field robots and operate in dynamic environments. Robotics have become common in many industrial and production operations because they have proven to be extra robust, safe, proficient, precise, and dynamic. There are specific areas of application in which robots could be of assistance in the industry. The feasibility of using robots in building construction depends on comparison of robotic versus labor-intensive performance of appropriate building tasks. This paper presents the growth opportunities of robotics in construction by savings in human labor and its impact on costs.

| Key Highlights |

|

Introduction

Replacing human labor with robots at construction sites is gathering pace and is expected to be a future trend. While there may be some attrition in this trend, the most probable scenario is that robots will be used alongside human workers to enhance their work, keep them safer, and improve productivity. The current capabilities of existing robots coupled with a growing labor shortage will undoubtedly lead to robots handling some of the more unskilled repetitive tasks, leaving human employees to focus on other aspects of their jobs. There are a few diverse types of construction robots that are poised to enter the construction industry on a mass scale. First is a 3D-printing robot that can form large buildings on request. A portable robotic arm controls a 3D-printer, and with a set of preprogrammed commands, this system 3D prints a complete structurally-safe building.

This technology is also beginning to be used for construction of bridges, with the first ever 3D printed bridge recently being constructed in the Netherlands. This duo of 3D printing and industrial robots is some of the most trending automation technology in the construction industry. There are construction robots for brick-laying and masonry, and robots have also been used to lay an entire street in one go. These types of robots improve the speed and quality of building work. There are several other types of construction robots, such as remote controlled or autonomous vehicles, but the few cited above are the most used in current construction locations and may be the most impactful. As a highly labor-intensive manual industry, construction robots will have a major advantage in the construction industry.

As construction companies look to program more and more tasks for the sake of proficiency and productivity, demand for construction robots will steadily increase.

Innovation of Robotics in Construction

In recent decades, robotic technology has developed significantly. This slow but continuous development has allowed robots to start penetrate a number of diverse domains of human activity. Construction is undoubtedly one of the areas that has begun to embrace robotic tools. The use of robots can be a huge game-changer for the industry given the fact that robots can be programmed to perform a plethora of tasks.

Exoskeletons for Construction Workers

Exoskeletons can be tremendously valuable for construction workers. They can decrease injuries on construction sites and allow workforces to do their job more quickly and proficiently. Exoskeletons help a lot in suitably balancing the lifted mass and contributing to great strength when using heavy tools.

3D Printing Robots

Another type of robot that can have a significant influence on the construction industry is 3D printing robots. The recent example of the 3D printed bridge in Amsterdam stated above surely is impressive. Some of the biggest advantages of a 3D printing robot are the extraordinary precision during the construction process and the capability to put together new and exciting types of architectural structures. On top of that, the time needed for project close-out can be notably reduced.

Demolition Robots

Demolition robots are an additional type of construction robot that can be used in mainstream applications. While such robots are easier to deploy than demolition crews, they are far safer and inexpensive when it comes to demolishing concrete and structural components of a structure at the end of its lifecycle.

Self-Driving Vehicles

Vehicles that are capable of moving independently are now part of the building process in mining-related tasks. Self-driving trucks can offer significant value as they can increase on-site productivity and diminish cost. Safety is also an added advantage as this kind of machinery can operate autonomously in highly dangerous areas or regions (e.g., mines).

Evaluating Where to Invest in Robotics on the Basis of Value and Maturity

Incorporating robotics technologies into the enterprise and then running day-to-day actions will require entirely new skill sets. Today, construction companies have civil engineers, architects, supervisors, foremen, laborers, and mechanics. But moving forward, the need for data scientists, analysts, and software engineers is increasing. Not only are these skills different, they are rare and in demand by many companies in many different industries. This will create the need for construction companies to progress new employee value propositions, make tactical acquisitions, and enter into partnerships and joint ventures.

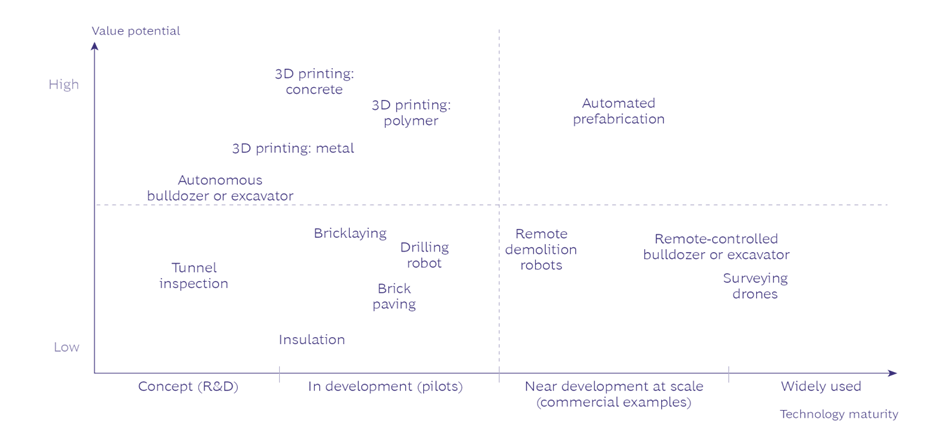

New players from technology and neighboring industries are inward-looking towards the market and pushing the limitations of traditional construction processes. Given the very tangible risk of falling behind, companies need to pursue pilot schemes to experiment with innovative robotics applications and capitalize on scaling up solutions. Construction companies do not have the luxury of waiting five years to see which technologies pan out. By that time, the first movers will have marched in and captured the benefits while those that took a wait-and-see approach could find themselves at a competitive disadvantage for years. Ideally, companies will implement a portfolio management approach for investments in robotic applications.

Advancements in robotics technologies indicate seismic change in the construction and property development industry. Companies need to start planning now, putting the right digital abilities in place, creating strategic bets, positioning the culture toward experimentation, and recognizing partners to create an integrated business model. The first early adopters stand to advance important cost and competitive advantages. The laggards will find themselves trying to catch up with early adopters for years.

Benefits of Construction Robotics

Introducing robotics into the construction process has a variety of potential benefits.

Cost Reduction

One of the biggest advantages to construction firms is cost reduction. Construction robots can execute certain tasks with superior speed, accuracy, and efficiency compared to humans, and so repetitive, laborious tasks can be completed faster, more easily, and with fewer mistakes. Reducing the time taken helps keep assignments on track, while higher accuracy means projects are more likely to remain low-priced since less time is consumed having to fix glitches or errors. While construction robots do require up-front capital as well as maintenance, they do not need wages or breaks, and their speed and precision saves money in the long term.

Waste Reduction

Construction firms are progressively moving toward lean practices, and a key factor is reducing waste. In construction, waste consists of both defective and overproduced parts and materials, as well as misused time and work due to underutilized workers or errors during construction. Construction robots reduce waste, increase efficiency, and save time and money through ensuring accuracy and exactness, as well as more uptime than a project that relies mainly on human labor.

Increased Worker Safety

As construction robots are becoming common, the role of human labor in construction projects is changing. Rather than undertaking unsafe, unpleasant, or highly repetitive tasks themselves, human workers instead manage robots that perform such tasks. Construction robots can handle dangerous materials more safely and can be placed into situations that are too dangerous for humans. There is also a smaller amount risk of injury to workers, either from performing a detailed, dangerous task or repetitive tasks.

Increased Speed

This increased accuracy and efficiency, pooled with a construction robot’s ability to perform tasks carefully and without breaks, means that construction projects that use robots can be finished extremely quickly. Construction robots have built entire houses in just two days.

Conclusion

The construction industry is one of the least automated industries that feature manual-intensive labor as a main source of yield. Whether it is greenfield commercial construction, renovation, or demolition, robots do not yet play a significant role in any step of a building’s lifecycle. However, there are numerous new robots under development and in the early stages of deployment that could change this. As a highly un-automated industry, construction is poised for a robot technology revolution

Construction companies have not generally been at the forefront of innovation, but new and approaching advances in robotics, such as the increasing capability to work in undeveloped, unstructured work sites and interact with human workfellows, along with a persistent drop in costs promise to change that and profoundly disrupt the competitive landscape.

References

https://pdfs.semanticscholar.org/1f9c/b09c36c15d38605184d17f720e277e0693f0.pdf

http://www.constructionworld.org/6-ways-robotics-transforming-construction-industry/

https://www.robots.com/articles/innovations-in-construction-robots

https://www.constructconnect.com/blog/construction-technology/robots-coming-construction-site/

https://www.robotics.org/blog-article.cfm/Construction-Robots-Will-Change-the-Industry-Forever/93

https://esub.com/how-robots-are-changing-construction/

https://www.cbc.ca/news/technology/construction-robotics-3d-printing-mit-technology-1.4086174

https://blog.robotiq.com/how-robotics-could-change-the-future-of-construction

https://online.jefferson.edu/construction-management/construction-robotics-changing-industry/

https://www.bcg.com/en-in/publications/2018/robotics-property-development-building.aspx

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe