Fermentation-derived vanillin could be a sustainable natural alternative to synthetic vanillin

Abstract:

The perception of the growing population to live a healthy lifestyle is on the rise. In that context, the new structure of labeling called “Clean Label” is taking on the food industry. These labels are made easy to read and highlight any ingredient that is derived from artificial source, making it easy for consumers to make “healthy” purchase of their daily groceries. While striking a balance between health and flavor is where food companies aim to shine at, it is quite difficult due to technical limitations. One of the most commonly used taste enhancer and a classic flavor is Vanillin (Flavor compound of Vanilla) which is used on an extensive list of food categories such as beverages, chocolates and confectioneries. While just 0.5 percent of the vanillin produced is derived from natural vanilla pods, the remaining 99.5 percent of the global vanillin is made from artificial sources such as fossil fuel and lignin. With increase in demand for natural flavors and Vanilla, it is essential to identify an alternative method to manufacture vanilla that can be classified “natural”.

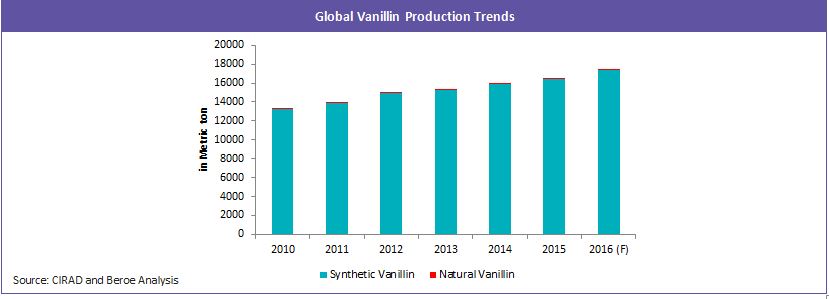

Key Highlights: The demand for vanilla is increasing every year at around 3-5 percent CAGR due to increase in new food products. The global vanilla market is composed of 99.5 percent synthetic vanillin and 0.5 percent natural vanilla (FAOSTAT). The acceptance of synthetic vanilla derived from crude oil and wood pulp is severely under contemplation by consumers due to the possible negative health effects from consuming it. Furthermore, the feedstock of these synthetic vanillin is neither sustainable nor is the natural vanilla bean market improving due to low yield, intense manual labor, long processing time, etc. Fermentation derived vanillin is expected to be the next best thing which could replace synthetic vanillin due to its sustainability and its flexibility to be termed as natural.

Importance of finding a sustainable vanilla alternative:

- While the global population is shifting their preference towards wholesome ingredients due to increased awareness on healthy lifestyle, it becomes increasingly challenging for food companies to satisfy this from their procurement point of view. This demand by the public has led to a new classification in food labeling termed as “clean label”. This means that the label on the food container should disclose the ingredients highlighting the artificial ingredients, if any. This makes it easy for customers to make their purchase decisions.

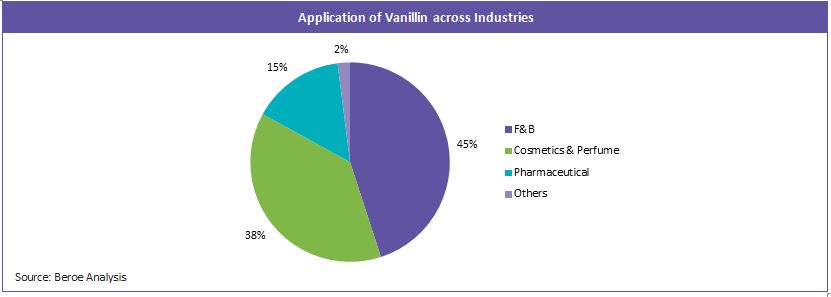

- Flavors and fragrances have been increasingly evolving over time. However, specifically Vanilla has been the most used and preferred flavor across all categories in food. Having said that, 99.5 percent of vanilla flavoring used currently are made from fossil fuel or wood pulp. While it is hard to believe that such complex flavor is extracted from crude oil and wood and is not sustainable on a longer run, the downside is that it cannot be claimed as a natural flavor. Synthetic vanillin, priced around $10 – $20/Kg, is cheaper and more concentrated; even a very small volume is enough to flavor a batch.

- The rest 0.5 percent of vanillin is processed by cultivating vanilla pods. While vanilla pods set the benchmark flavor for vanilla, producing them is expensive, labor intensive, time consuming and is easily affected by changing weather conditions. The yield of vanillin extracted from vanilla pods is extremely low; it takes 500 Kg of vanilla pods to obtain 1 Kg of vanillin. Naturally, vanilla pods are odor neutral as they have glucoside in an inactivated form and the vanillin is freed through curing the beans for roughly around 6-12 months. Given the tedious and lengthy process involved in its extraction, natural vanilla is the 2nd most expensive spice in the world with prices ranging from $1500 – $2500/Kg.

- Manufacturing vanillin through fermentation has been discovered and commercialized by Solvay (previously called Rhodia) and Evolva in association with IFF (International Fragrance and Flavors). Solvay in association with Givaudan use rice bran as a feedstock and convert it into Ferulic acid which is then fermented using unmodified yeast to produce Vanillin. Evolva and IFF follow similar concept of fermentation but use sugar with brewer’s yeast. Vanillin produced by both these methods can be labeled as natural vanilla flavor. According to food regulation US FDA 21CFR101.22 and Europe 1334/2008, food products that are produced through microbial fermentation can be labeled “natural”.

- The raw materials for producing natural vanillin from the two mentioned methods are rice bran, sugar and brewer’s yeast. Rice and Sugar are major commodities, brewer’s yeast is the by-product of beer making and currently is available in abundance; it is being researched for improved applications across different categories. With the feedstock forecasted to be at good volume in the near future, it is safe to say that the sustainability is very good for vanillin.

- Having noticed the shift in buying preference of consumers, Nestle had already informed their customers that they will change to naturally flavored vanilla in around 250 of their products.

Conclusion:

It is evident that consumers want natural ingredients in their food and are ready to shell out extra cash for it. However, the yield of natural vanillin from vanilla beans is extremely low when compared to other options and the processing time is also longer. Also the cost of natural vanillin is high at around $1500 – $2000 for a kilogram. Considering these parameters, it is quite evident that a natural vanillin substitute is essential. While fermentation-derived vanillin is available, it is early to comment on its market position compared to synthetic or natural vanillin. It is suitable for food manufacturers, it is sustainable, can be labeled natural, reasonably priced and it can effectively replace synthetic vanillin in terms of volume. Considering the current market, it is safe to say that fermentation-derived vanillin has the upper hand in replacing synthetic vanillin. However, its flavor is no match for vanillin derived from vanilla beans.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe