Energy audit helps reduce costs

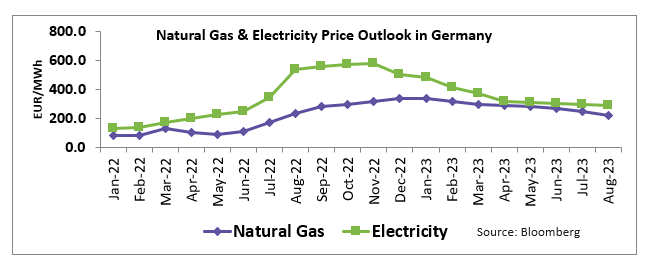

Increase in energy costs in Europe

The energy costs in Europe have been increasing to record level highs amid the ongoing Russia–Ukraine conflict. The reduced supply of gas to Germany via Nord Stream has raised multiple alarms across Europe, and most countries are prepared to reduce demand. The supply of gas through the Nord Stream 1 pipeline is highly uncertain and can increase the supply risk across Europe. Russia has announced a three-day shutdown of the NS 1 pipeline, citing maintenance issues and also declared that it would indefinitely hold gas flows through the pipeline, citing sanctions imposed by Western countries on Russia. This is expected to increase the uncertainty of gas supply across the region and its availability during the winter months. To mitigate this, the European Union Council has asked member states to reduce each individual country’s gas demand by 15 percent. Although this can offset the impact of Russia stopping the gas supply in Europe to an extent, companies still have to worry about the high energy costs that are expected to prevail in the next 3–6 months. The increased prices of natural gas act as a catalyst for the increase in electricity prices, which are already high enough to meet the cooling demand in Europe with heat wave conditions. Energy prices in Europe increased once again in August 2022 after the Russian gas giant Gazprom announced that it would turn off gas for three days in the first week of September, citing maintenance issues. The supply of gas from Russia is highly volatile and uncertain, and it is the main driving force of energy commodities in Germany as well as the rest of Europe.

Need for energy audit:

With many companies suffering from increasing energy costs, the need for energy efficiency has increased in an unprecedented manner in Europe for both its nations as a whole and individual companies as well. The countries are expected to develop a road map to reduce gas consumption by 15 percent and present a strategy to the EU council. If Russia stops the gas flows through the Nord Stream 1 pipeline, then Europe is expected to face a shortage of 45 billion cubic meters of gas, which is 15 percent of its demand, and hence, the council wants the member states to reduce the demand of each country by 15 percent2. In addition, increased energy efficiency would help companies to increase their profitability and become energy resilient during these tough situations and energy crises in Europe. The energy-saving measures suggested by energy consultants can not only reduce energy consumption but also increase the overall productivity of the process, thereby reducing the specific energy consumption of the product/service of the company.

In any industry, energy, labor, and materials are the three main operating costs. Of these, energy is by far the only component that can be optimized by any industry or commercial building. Hence, energy efficiency and energy audits are of great importance to maximize the profitability of the company and reduce energy costs. Energy audits are conducted by third-party vendors who have certified energy auditors to understand the processes of various industries and identify energy-saving opportunities.

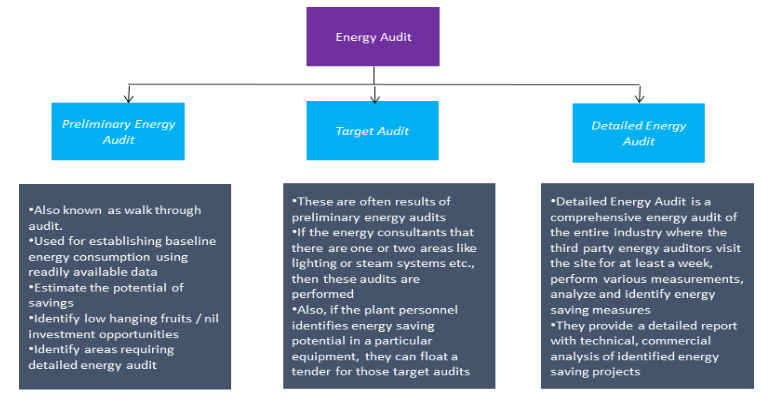

Energy audit methodology3:

Energy audit is a technical study conducted by multidisciplinary engineers, such as electrical, mechanical, and process engineers, to reduce the overall energy consumption in various industrial sectors, including commercial buildings, metals, power, cement, Pharma, and manufacturing units. An energy audit can be defined as the “monitoring, verification, and analysis of use of energy and submission of a technical report containing energy-saving opportunities identified during the study period along with the cost–benefit analysis and action plan to reduce energy consumption”.

The type of energy audit depends on the type of industry, depth of audit required by the client, and magnitude of cost reduction required.

Role of plant personnel during an energy audit:

-

First, it is very important for any industry to have a dedicated energy manager who takes care of daily energy reporting and energy efficiency issues.

-

The appointed energy manager is expected to be a single point of contact for a third-party energy-auditing company.

-

The energy manager of the plant shall coordinate with the individual department heads and the energy audit company to facilitate ease in carrying out measurements and helping the audit company to understand the process.

-

The industry carrying out an energy audit shall run at almost full load capacity during the study of the detailed energy audit period, as the equipment is expected to have correct efficiencies only under these conditions.

-

Cooperate with the audit company team in performing various measurements.

-

Facilitate periodic meetings with department heads and audit teams on energy-saving opportunities.

Role of the energy audit team during the audit:

-

First, it is very important for an energy audit team to have an industry expert therein, such that the expert has in-depth process knowledge of the industry.

-

It is good to have a team of certified energy auditors with rich experience.

-

Perform all the necessary measurements with accuracy.

-

Have day-to-day meetings with the concerned department to discuss daily findings.

-

Prepare a final presentation and present all energy-saving opportunities on the final day of the energy audit.

Role of the energy audit team after the audit:

-

The energy audit team shall prepare a detailed energy audit report on the findings relating to energy-saving opportunities.

-

The report shall have a technical analysis of the identified projects and approximate calculations of energy cost savings and investment required for the projects (if any).

-

The audit team shall support the plant team during the implementation of projects on technicalities

-

Sometimes, the audit team is expected to help the plant team with various suppliers that can provide energy-efficient projects identified during the audit period.

Conclusion:

Attaining energy efficiency in any process industry or a commercial building is a continuous process, and the best in-class companies reduce energy consumption through the advisory of in-house energy efficiency teams and third-party energy consultants. The industry that has performed an energy audit is expected to prioritize the identified energy-saving projects, such that they implement nil investment projects first, followed by low investment projects, and then high investment projects. The identified investment energy-efficiency projects can be installed by energy service companies (ESCO) through their energy performance contracts. These contracts eliminate the capital risks associated with capital-intensive projects on customers. Customers can pay the ESCO through energy cost savings achieved on a monthly basis.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe