Shifting to outsourcing model will benefit control tower services

Abstract

Control tower solution is highly adopted across the globe to bring supply chain visibility and to benefit with reduced operational cost. Most of the industries adopt two types of models – insourcing and outsourcing. Insourcing model is adapted by engaging with supply chain visibility solution providers capable of providing IT integration (for example, Amber Road, E2Open, Informore, etc.) by implementing software integrations such as SaaS and Cloud-based solution in their own premises. Outsourcing is another commonly followed model which requires engaging with the 4PLs with the capability of offering end-to-end supply chain visibility platform (for example, DHL, Damco, Kuehne + Nagel, etc.)

Industries face challenges in the insourced model while setting up control towers across various geographies. These include maintenance of the installation and training the employees for adapting the model. Lack of strategy and ideology in the process makes the effort and investment unexploited. In outsourced model, engaging with 4PLs and supply chain orchestrators helps in creating more visibility with the help of technological advancements and skilled workers. 4PLs with technological expertise act as an interface between the 3PL and the buyer. This improves the visibility in the complete supply chain management.

| Buyers with higher shipment volume >5,000 containers/per month prefer to engage with 4PL service providers such as DHL, Damco, and Kuehne + Nagel, with dedicated FTE to attain higher cost benefit by focusing on strategic solutions |

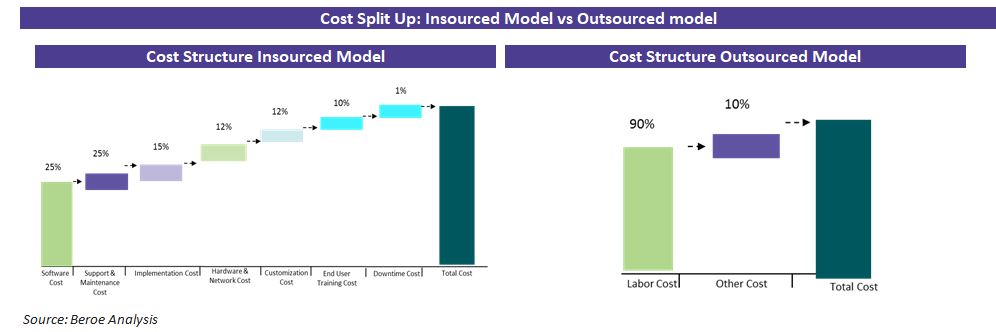

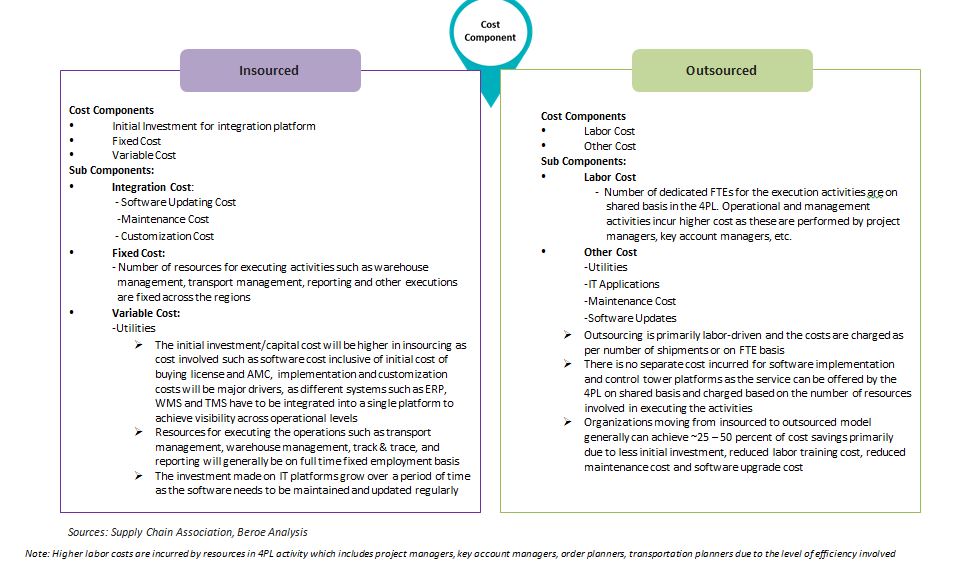

Cost benefits in moving from insourced to outsourced model

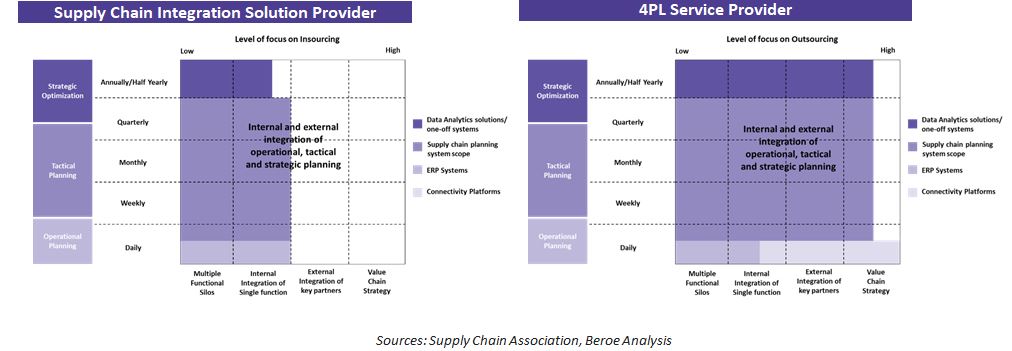

In traditional insourced practice, a centralized hub provides visibility by integrating IT platforms on a local to global level to gain full coverage on the functional scope.

In outsourced model along with functional integration of IT platforms, there is more focus on planning, future impact, visibility and strategic solutions such as structural designing.

Depending on the shipment volume, industries prefer to insource or outsource the supply chain functions. In general, industries with volume greater than 5,000 containers per month tend to outsource operations to a 3PL or a 4PL such as DHL and Damco. In case the volume is lower, companies go for supply chain solution providers such as Amber Road and Informore to integrate the IT platforms within their organizations.

Type of Control Tower Service Providers

In Sourced Model: End-to-End Supply Chain Visibility Solution Provider

Suppliers such as Amber Road, Informore, and E2Open provide visibility by connecting all the IT platforms within the organization as a single IT solution either through horizontal or vertical collaboration for analysis and reporting.

Outsourced Model: SCOs and LLPs

Supply Chain Orchestrators: SCOs do not offer any direct logistics services (freight forwarding, customs brokerage, contract logistics, and trucking, etc.) to the buyer, rather they help the buyer in terms of coordinating and managing their 3PL supply base by acting as an interface between the 3PLs and the buyer.

Lead Logistics Providers: LLP directly engages with the buyer and provides all the execution activities, including logistics services and management services.

Control tower visibility parameters considered in moving from insource to outsource

Industries outsource or insource their supply chain management functions to achieve higher efficiency in operational and strategic management by focusing on more visibility.

|

Operational |

|

|

Tactical |

|

|

Strategic |

|

Case Study

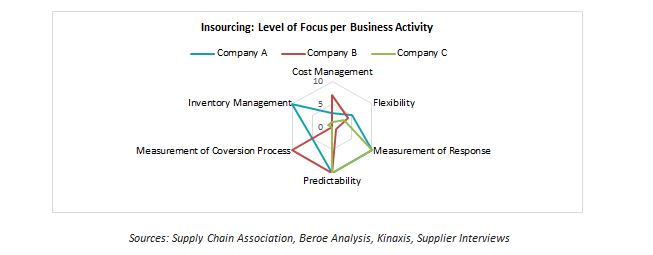

Description: Organizations with different verticals such as telecommunications, electronics and logistics engage with end-to end supply chain solution providers for integrating their IT platforms.

Industries engaging with Supply Chain Solution Providers (IT Integration Suppliers)

|

Company |

Company A |

Company B |

Company C |

|

Industry |

Telecommunication |

Electronics |

Logistics |

|

The Company’s Demand Market |

Global Market |

Global Market |

Global Market |

|

IT Integration Platform |

Cloud-based Integration |

Hybrid Integration |

On-Premise |

|

KPIs Implemented - Tactical Management |

Inventory management

delivery

Performance (CLIP)

Performance (RLIP) |

End-to-end performance

|

Communication Performance

Productivity

|

|

KPIs Implemented -Operational Management |

Operations

|

Service Operations

|

Shipment / delivery performance

(carriers and customers) |

|

Strategic Management |

NA |

NA |

NA |

Collaboration within the operational units such as manufacturing, inbound/outbound transportation, warehouse and inventory management can be achieved in the insourced model. However, complete focus on the entire supply chain functions cannot be achieved in the insourced model compared to outsourced model.

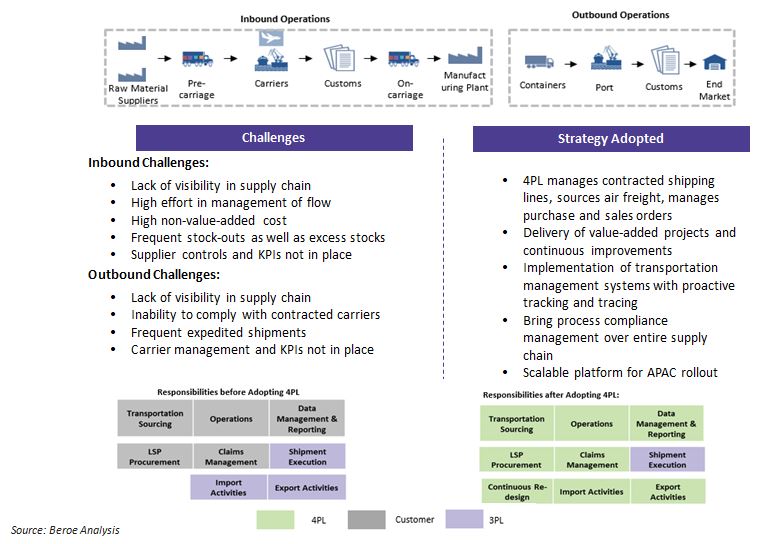

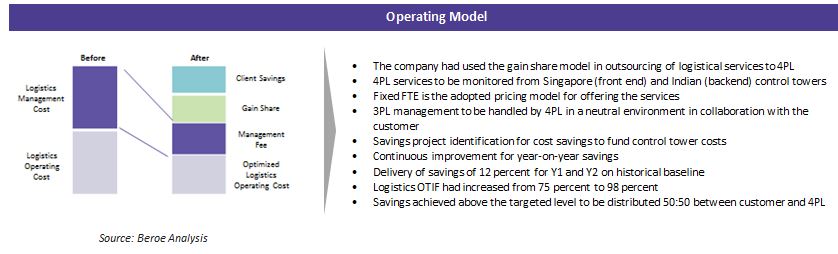

Case study: Agricultural goods company adopting 4PL across APAC

Description: This case represents the 4PL (SCO model) strategy adopted by a global industrial leader in the agricultural goods sector. The company has eight factories in APAC, with their flow of goods, including raw materials and finished goods, across 70 lanes, 28 shipping lines, and 15 freight forwarders (including sea, air, and road). It had challenges such as less control and less visibility on the cost with its current system of operating with 3PL across APAC.

Conclusion

Which industries can outsource supply chain operations?

Industries such as food and beverage, chemicals, beauty and cosmetics, personal products, retail and e-commerce, pharmaceutical, hi-tech, banking and financial, and automotive can practice outsourcing. However, volume is the key factor to be considered while choosing a 4PL service provider. If the volume is greater than 5,000 containers/month, industries can negotiate better in gaining cost benefits.

What are the major cost benefits in outsourcing over insourcing practice?

Organizations moving from insourced to outsourced model generally can achieve ~25 – 50 percent of cost savings primarily due to less initial investment, reduced labor training cost, reduced maintenance cost and software upgrade cost.

How does outsourcing benefit procurement organizations?

For industries with higher volume, insourcing can only provide limited visibility in operational and tactical level within the organizational functions. However, outsourcing to a leading 4PL service provider can be beneficial in terms of availability of high quality manpower to supervise vendors and ensure continuous process improvements by focusing more on strategic level operations on achieving end-to-end supply chain visibility.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe