Carbon Capture Storage– Constructing A Technological Environment

Abstract

The global construction industry is expected to grow by an average of around 4–5 percent between 2016 and 2019, with the US, China, and India expected to hold approximately 50 percent of the share, worth $8.9 trillion, in incremental construction spent over the next 15 years. The power and industrial construction sector contributes to 10-15 percent of the industry in various countries, such as the U.S., the UK, China, etc. and is a key driver for economic growth. Hence, these industries are also the largest waste generators in the world. Waste management and sustainability are challenges currently faced by the construction industry globally. Several initiatives, such as LEED certification, BREEAM – NL, Construction Products Regulation, etc. have been implemented to address these issues. ’Carbon Capture Storage’ is one such initiative that has gained traction globally.

This concept has been successfully implemented in various regions across sectors in the Engineering & Construction industry. The European Union, the U.S., and various other countries have been actively involved in this green initiative by signing the ’Paris Agreement’. The target set for this proposal is that by 2050, the global temperature increase will be controlled to below 2 degrees Celsius above pre-industrial levels, and additional efforts will be made to increase the limit to 1.5 degrees Celsius.

| Key Highlights |

|

Introduction

- Climate change has been an ongoing topic for discussion for decades. However, the Intergovernmental Panel on Climate Change (IPCC) has found that the carbon dioxide emission levels should be reduced by 50-85 percent globally by 2050. According to the International Energy Agency (IEA), the demand for energy is expected to increase by 45 percent globally by 2030. To sustain the demand, fossil fuels are increasingly used in developing countries. Further, an increasing number of industrial facilities in the chemical, steel, and cement sectors will lead to higher carbon dioxide emissions. This can be significantly reduced by adopting the ’Carbon Capture Storage’ concept that decarbonizes energy and reduces carbon emissions in industrial facilities.

- Measures are being taken by the governments of all countries to address these issues. The Paris Agreement has been signed by 194 countries, out of which 177 countries have ratified the agreement. The U.S., China, and India are the three largest greenhouse emitters that account for approximately 42 percent of global emissions. However, the U.S. has applied to exit the Agreement after 2019. The European Commission has taken a special interest in addressing these issues and has set up various rules and regulations to be followed by every country with particular emphasis on carbon capture.

- This approach has led to the development of carbon capture storage technologies that will lead to maximization of carbon storage capacities and drastic reductions in CO2 levels. Estimations made by the UN Environment Program show that the various improvements made to the European construction industry can reduce carbon emissions and achieve energy efficiency of more than 30 percent in the future.

Carbon Capture Storage—CCS

- Carbon capture storage is a technology that is in state of continuous development. It can capture and store almost 90 percent of CO2 emissions from power plants and industrial facilities. The use of this technology along with renewable biomass will result in a carbon-negative environment and makes it one of the limited carbon abatement technologies currently available.

- Carbon capture storage technology mainly consists of three parts:

-

- Capture carbon dioxide

- Transport carbon dioxide

- Store carbon dioxide in allotted storage facilities

- Capture: One of the three capture methods, i.e., oxyfuel combustion, pre-combustion capture, and post-combustion capture are used to separate carbon dioxide from other gases in power plants or industrial facilities.

- Transport: The separated carbon dioxide is then transported by ships or pipelines to the storage facility locations.

- Storage: This carbon dioxide is then stored in pre-selected locations that are underground rock formations.

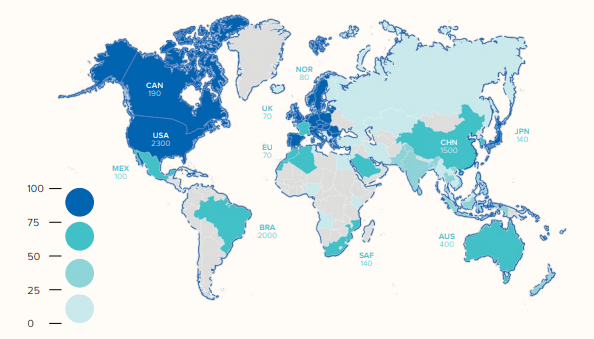

Global Storage Resources - 2017

Source: Global CCS Institute

Storage estimates are in gigatonnes of CO2. Color differentiation is based on the detailing and design of the existing and prospective CO2 storage resources.

CCS Storage Facility Construction—2018

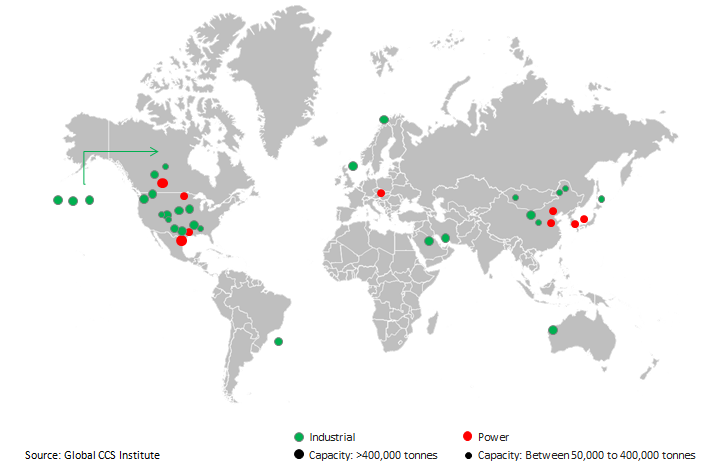

- CCS Locations: According to the Global CCS Institute, around 17 facilities worldwide are operational with a capacity of around 30 Mtpa of carbon dioxide and 5 facilities are under construction, which will be completely operational by H2 2018 and H1 2019. This capacity will increase by around 6 Mtpa of carbon dioxide. In addition to these facilities are 15 smaller capacity storage facilities that are operational or under construction. Their capacity ranges between 50,000–400,000 tonnes per annum. The smaller storages facilitate carbon dioxide capture of over 2 Mtpa of CO2.

|

Project Stage |

U.S. |

Canada |

Brazil |

China |

Australia |

South Korea |

Norway |

UK |

Saudi Arabia |

UAE |

|

Early Development |

0 |

0 |

0 |

6 |

1 |

2 |

0 |

2 |

0 |

0 |

|

Advanced Development |

2 |

0 |

0 |

1 |

1 |

0 |

1 |

0 |

0 |

0 |

|

In Construction |

0 |

2 |

0 |

1 |

1 |

0 |

0 |

0 |

0 |

0 |

|

Operating |

9 |

3 |

1 |

0 |

0 |

0 |

2 |

0 |

1 |

1 |

|

Total |

11 |

5 |

1 |

8 |

3 |

2 |

3 |

2 |

1 |

1 |

Source: Global CCS Institute, CCS Association

The period between 2017 – 2020 will see the construction of CCS facilities for iron & steel production in Abu Dhabi, chemical production in Illinois and Yanchang, power generation in Petra Nova, natural gas processing in Western Australia, and oil refining in Canada.

Global Carbon Capture Storage Facilities – Operational and On-going Construction (2018)

Cost of CCS

CCS is an increasingly effective method to capture and store carbon dioxide and reduce carbon emissions globally. The cost of each project can vary based on the source of carbon emissions, the distance from the source to the storage facility and the specific characteristics of the storage facility. CO2 capture constitutes the largest portion of the total cost. The cost of CCS projects in the power sector are expected to decrease from €60-90 per tonne currently to €35-50 per tonne by 2020-2025.

Cost Outlook based on Sectors–2017

|

Sectors |

Natural Gas Processing |

Biogas to Ethanol |

Fertilizer |

Super critical PC |

Oxyfuel |

Iron & Steel |

Natural Gas |

IGCC |

Cement |

|

$ per tonne CO2 |

20-27 |

21-27 |

23-33 |

60-121 |

63-121 |

67-119 |

80-160 |

81-148 |

104-194 |

Source: Global CCS Institute, CCS Association

Conclusion

- The Carbon capture storage technology is still an expensive and new technology that is in the realization phase. Several projects have been deemed as failures worldwide mainly due to cost and environmental concerns. However, to reach the required levels of below 2 degree Celsius by 2050, the construction of such CCS facilities plays a critical role. The increasing need and growing demand for cost-effective solutions have also led to increased R&D in this field which have yielded positive scenarios. This change can be brought about by adopting this technology and following government initiatives/regulations pertaining to the technology in the respective countries. The largest CCS plant, Petro Nova, in Texas, is currently running successfully, and the CCS technology is believed to be a game changer in terms of establishing a carbon-negative environment.

Recommended Reads:

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe