Blockchain enables building digital thread for additive manufacturing

Abstract

Additive manufacturing (AM)/ 3D printing is enabling manufacturing capabilities through digital means which is not possible through conventional manufacturing processes. The digital nature of AM means that with the help of digital thread parts, the products of AM process can be easily shared and transmitted within the distributed supply chain. Digital thread also acts as backbone for AM by carrying information from design phase to feedback and continuously monitors the parts in use.

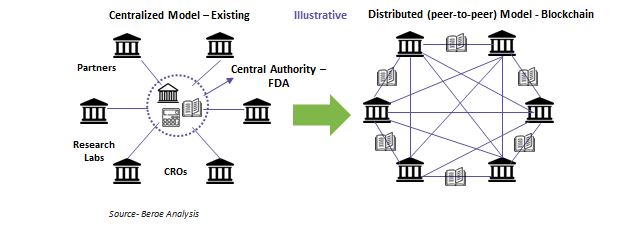

Digital thread also enables faster production of parts as data related to manufacturing is already saved in it and the feedback loop will help in continuous improvement of product output by sharing performance-related data of product in use. The distributed model of DTAM (Digital thread additive manufacturing) across number of partners and disparate locations creates potential for data theft or tampering. To tackle this, DTAM implementation requires a strong data protection framework such as blockchain. When linked to DTAM, blockchain will add a watertight security layer to protect data. It will also act as middleware to integrate and connect the digital thread.

Market Overview

Additive Manufacturing / 3D Printing

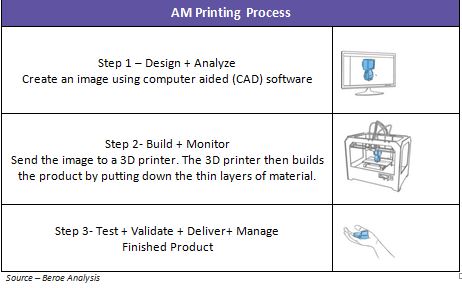

Additive manufacturing (AM)/3D Printing is a process of adding layer upon layer to form a three dimensional model. It enables transfer of data from CAD to a 3D printer. The printer can then take a 3D model of the product computing it into thin, horizontal cross sections. These are printed on the alloys or sand cast and laid one on top of the other to form a final product. Additive manufacturing can be used to produce a final product or an indirect product which requires mold, assembly, heat, and finishing.

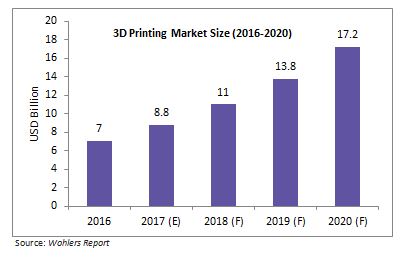

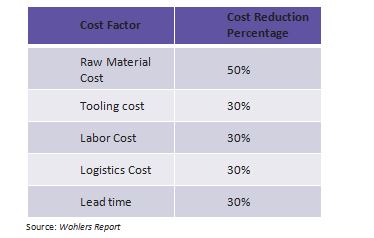

AM industry is growing at a CAGR of 25 percent and it is forecasted to reach $17 billion by 2020. Enterprise AM will realize in the next 2-3 years while it takes 5-10 years for the consumer printing to evolve. Currently, 3D printing is in version 3.0 build phase. However, its adoptability is still at the early stages. A majority of companies are still experimenting with the application of 3D printing in their respective domains. Potential savings that can be achieved through AM is as below.

Digital thread

Digital thread is a single strand of data that stretches from initial design phase to finished product, constituting data that will enable design, modeling, production, and use and monitoring of a part manufactured through AM. Digital thread enables flow of data throughout manufacturing process from design process to post production monitoring and inspection.

Blockchain

Blockchain is a distributed database maintaining continuous growing list of transaction records called blocks, each block is linked to previous block and contains timestamp. Database is shared among manufacturers and suppliers and all the members have to collectively validate updates, entries are permanent and can be searched thus making possible to view entire transaction details. A set of predefined and agreed upon rules will help to update, validate data.

Digital thread for AM process by infusing blockchain

DTAM faces challenges to integrate software, multiple printers, and multiple manufacturing locations which are disported and physically disconnected. Additional challenge is to record data and events during AM manufacturing process which is required for quality testing and certificates. Thus blockchain provides security layer and middleware to integrate and connect digital thread. Below case scenarios will help in examining the block chain role in AM process.

Step 1- Design + Analyze

In this phase, data often switches between CAD systems to analysis tools to design software. Instead of using PLM (ERP) Systems blockchain can be used which will have a timestamp record of these changes and can be distributed across departments and multiple organizations and act as a ledger accounting all state changes in a decentralized fashion.

Blockchain provides a platform for file signatures to be tracked across platforms to maintain traceability especially when loading data to and from cloud platform; it also ensures files are not tampered while moving across intermediary software tools.

Step 2- Build + Monitor

This is the phase where digital model created is transformed to a physical product; this is a critical phase as data created in design phase is used to build a product, the data used in creation is useful in certification. This phase faces challenges from the distributed nature of AM across supply chain as product build happens across multiple locations requiring systems and infrastructure to track control, process feedback and collect data.

These challenges can be addressed using blockchain in context where it is manufactured when needed at a point blockchain serves as a tamper resistant transaction layer.

Blockchain will transact records of sensor data sets and maintain individual past history when data is not stored in one system but distributed across systems. It also provides a mechanism to record digital fingerprints of captured data sets to validate and record transactions.

Step 3- Test + Validate + Deliver + Manage

Test and validate phase of DTAM involves inspection for both digital and physical domain, the major challenge during test and validate would be to try records created for the inspection of individual part with the digital model responsible for its creation. Since blockchain contains part history it can transact records to understand and track flaws and tolerance measurements, blockchain also offer append only functionality to validate necessary steps that took place as a part of qualification and certifications. Once the verification and validation data is distributed in network, blockchain allows for transaction and recording layer to be one and same ensuring accurate attachments of test results or modification of data to the original files.

In delivery and management part of this phase, product is put to use in fields and data is collected through integrated sensors and monitors which are fed into feedback loops for continuous improvement. Blockchain provides a platform to track sensor data across platforms to provide attribution to original design, manufacture and distribution where IOT (Internet of things) is connected to blockchain.

Industries that can adopt DTAM

Aerospace, Defense and Manufacturing are the early adopters of AM technology and are growing at an average CAGR of 15-25 percent. DTAM is important to these industries as high importance is given to data security. For example, the manufacturing part breakdown-related data will help in improving product performance and even plant efficiency. Similarly in aerospace and defense, compliances on part data and patent is high.

Case study

Cubichain technology and CalRAM LLC demonstrated the deployment of blockchain network to track 3D printed aircraft parts from design, through printing, and certification to sales. The primary purpose of this joint demonstration was to fight counterfeiters as they can easily print the same parts on same equipment by having a part file. The demonstration helped in easy identification of part files which have been tampered by recognizing the difference in single data bit in the binary part file.

Conclusion

Blockchain beyond cryptocurrencies and other financial assets is gaining importance and its characteristics make it ideal for use in AM process. The concept of DTAM provides solution to secure and organize data generated across the AM process. Blockchain linked to DTAM will address each of the components of the digital thread such as architectural considerations of nodes and interoperability, infrastructure needs of information management, federation and standardization for the ability to manage and analyze data thus adding value across the supply chain.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe