Adoption of 3D laser scanning proves beneficial for construction surveying

Abstract:

One of the greatest challenges that a contractor or a project owner is likely to face during the execution of industrial, commercial or any other construction project is surveying the large area of construction site. Industrial and civil construction projects often involve surveying of a very large and intricate site area, using traditional surveying methods that are both time consuming and cost ineffective. As a result, the completion of such capital construction projects tends to face significant delays even before the actual construction starts.

In order to complete the construction projects on schedule, project owners and construction contractors can take advantage of the latest technology advancements in land surveying. One of the fastest growing technologies in surveying space is the 3D laser scanning. This article will throw some light on the need for adoption of 3D laser scanning and different applications on the 3D laser scanning in construction projects. In addition, the article also highlights advantages of adopting 3D laser scanning as against the traditional surveying methods and and providing few project implementation examples.

The construction industry has been slow in adopting new technologies and had not undergone any major transformation over the last 40 years. As a result, productivity has stagnated in most geographies and had even declined in a few cases. This scenario is expected to change over this decade in a significant way. In fact, changes are already taking place in the industry, but not on a truly global scale.

Many construction companies are incorporating new technologies and systems ranging from digital sensors, 3D printing, intelligent machines, mobile devices, and advanced software applications that are integrated with Building Information Modelling (BIM). One such technology is emerging as the future of the construction surveying – 3D laser scanning.

Over the last few years, 3D laser scanning has been used by contractors on many projects across the globe for surveying, mapping, improving the process design and reducing errors in data collection and documentation. 3D laser scanning technology can add value in the various stages of the project life-cycle. The challenge now is to achieve the widespread adoption and proper traction in the industry. Proper implementation of new technologies in construction projects, might lead to significant cost reduction.

What is 3D laser Scanning?

3D laser scanning technology captures the dimensions of space or objects such as project site and buildings using the lines of laser light. The output from the 3D scanner will be a point cloud image, which replicates the scanned objects. Depending on the type of 3D laser scanner used by the surveying specialist, objects can be scanned from up to several hundred meters. The data points from the laser scanner output can be collected to the accuracy of less than 5mm at speeds from several hundred to several hundred thousand points per second.

When an object (e.g., building or construction site) is too large to be surveyed or captured in a single scan, multiple scans from different sights are captured and linked to form a point cloud image. Once the 3D point cloud image is generated, the data is then exported to CAD or BIM application software to generate a 2D CAD drawing or 3D model replica. The 3D model can be used by architects and engineers for designing and executing projects with better accuracy.

Adoption of 3D Laser Scanning in the Construction Industry

Construction projects could be of varying complexities. The nature of the project and the final purpose of the laser scanning tends to impact the process the most. For most residential and commercial facilities, the land areas to be measured are minimal and hence, laser scanning can be executed with comparatively less effort and higher efficiency. On the other hand, for complex facilities such as industrial buildings with both complicated MEP (Mechanical, Electrical and Plumbing) installations, and detailed architecture and engineering design, it can take more time and effort for surveying during planning as well as execution phases. Hence, it is important for general contractors and property managers to plan for the accessibility of each space required for scanning.

One of the key challenges faced by the surveyors while scanning spaces such as operational buildings, tunnels, and mechanical shafts is the large volume of point cloud data generated after scanning, which could consume hundreds of gigabytes of memory space. Sharing this database with architects and sub-contractors located in different parts of the world could be a challenging and tedious process. Hence, there is a growing need to choose the right software and tools to process the scans and present it in the format that can be used by professionals to generate building design. However, most project owners are concerned about cost, time, accuracy and at times they are not sure what to do with the data generated out of 3D laser scanner. Understanding and overcoming these implementation challenges and issues linked with the 3D laser scanning technology will help owners and contractors improve the design and efficiency in their project portfolio.

Project owners and contractors are often more concerned about the cost while adopting new technologies in their projects. 3D laser scanning method is 10-15 percent costlier when compared to traditional surveying methods due to the generation of large amount of data and processing involved. However, labor expenses involved in the 3D laser scanning is more economical than the traditional surveying, which is an added advantage along with better accuracy of the scans generated. There are a large number of specialist service providers with extensive experience in providing 3D laser scanning survey. Property managers and even contractors often prefer sub-contracting surveying services to speciality surveying firm, to reduce cost and to avoid buying expensive surveying equipment.

With most of the construction projects having tight project schedules, general contractors and project owners alike are more concerned about the time taken to adopting and executing the emerging scanning methods. For most 3D laser scanning projects, the time required to scan and capture the data on-site can be reduced up to 50% compared to traditional survey methods. 3D laser scanning method captures more information or data points in much less time. In addition to saving on labor costs, the speed of data capture also makes it easier to schedule the survey work during times when fewer workers are on-site. Post survey, data processing requires limited time due to the advancement in software technology.

Finally, project stakeholders always care about the accuracy of the scan as it is crucial in the construction design process and execution. 3D laser scanning quickly captures 360-degree full scans as well as target scans, at a range of almost 1,000 feet with uncompromising accuracy. This helps designers and engineers to use the data with confidence for generating 3D models for projects. The ability to quickly capture highly accurate data points on construction projects can vastly improve productivity and reduce rework by identifying any deviations from design before it affects the project schedule and budget. Architects, engineers and other project stakeholders are increasingly beginning to see the value of implementing 3D laser scanning.

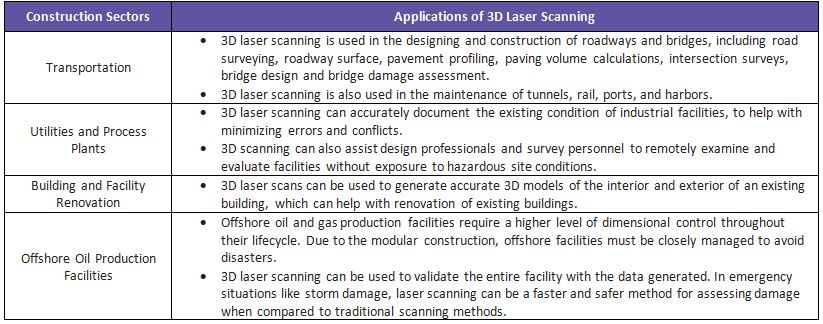

Applications of 3D laser scanning in different construction sectors

Despite the slow adoption of technology in the construction industry, 3D laser scanning currently serves many purposes and is also used in various sectors. 3D laser scanning uses vary from roadways and bridge surveying to industrial plant maintenance and retrofit projects. Some key sectors where 3D laser scanning is being currently deployed has been highlighted below:

Benefits of 3D Laser Scanning:

3D laser scanning is expensive than traditional surveying methods, but in some cases, the benefits outweigh the costs. When used appropriately in the projects, it can provide a greater depth of scan details and reduce project execution duration. Some of the benefits of using 3D laser scanning has been listed below:

Improved Planning and Design: 3D models generated by data point cloud from 3D laser scanning can improve the design by analyzing clashes and errors for a newly designed building prior to construction phase. The accuracy of dimensions and data obtained from 3D laser scans can help to improve the design, by providing exact measurements. These improved designs also minimize waste and eliminate rework.

Safety and Regulatory Compliance: Laser scanning methods are often safer than traditional methods (manual data capture methods) and are increasing adopted by global contractors to comply with health, safety, and environmental standards. The remote surveying ability along with quick data capturing capabilities reduce the time that survey professionals are exposed to harmful environments (especially when surveying nuclear and chemical facilities).

Cost and Schedule Reduction: It has been frequently reported by experts across the globe that 3D laser scanning can reduce total project costs by 5-7 percent and project schedule by 10-12 percent on industrial projects. The scanning can take as little as few hours to a few days, depending on the scale of the site, as compared with the traditional surveying methods.

All new emerging technologies are likely to have its own advantages and disadvantages that can be an adoption barrier and 3D laser scanning is no exception. Primarily, the cost of adopting or using 3D laser scanning is more expensive when compared with the traditional surveying technology. The price of 3D laser scanners can range from $50,000 to $150,000 and this does not include the cost of accessories or training costs. However post the transition, the surveying costs can be reduced significantly. Industry experts argue that 30 minutes of scan time on the field followed by 30 minutes of processing and uploading the data point cloud to the 3D CAD software can save around $30,000 in the total surveying cost, depending on the project scope.

Another potential barrier is the training requirement and change management linked to replacing an established working model. Training employees to adopt to this technology can cost time and money. The other hurdle is to ensure that there is enough hardware capacity to handle and process larger data sizes, generated from the 3D scans. Despite the challenges, surveying professionals and contractors have started using this technology (3D laser scanning) to attain better cost savings and improve building design. Few case examples of industry experts and contractors adopting 3D laser scanning has been captured below.

Case Study 1 - Gilbane Construction:

Gilbane Construction, a large construction management firm, started using 3D laser scanning for various projects worldwide with a significant reduction in project cost and execution time. Glibane’s John Myers, a virtual design and construction expert, who oversees the surveying project reports that “before scanning, they often experienced inaccuracies with survey designs, causing delays and rework.”

With 3D laser scanning, Gilbane is able to check and verify the designs, ensuring the measurements and dimensions are accurate before construction. Most importantly, 3D laser scanning enhances safety on the job-site. Workers do not need to risk themselves to record measurements in dangerous locations. The safer job-site saved significant insurance and liability costs for Gilbane Construction.

Case Study 2 – Heitman Architects:

Karl Heitman, founder of Heitman Architects reported that he has been using 3D scanners for various purposes. He also added that 3D laser scanning provided significant benefits in refurbishment and renovation projects. On one of the previous projects done by Heitman Architects, they have created a data point cloud of an 80-year old heritage building with accurate measurement using 3D laser scanners, which helped the sub-contractors to finish the renovation without a single change order and zero rework.

Even though 3D laser scanning is still nascent technology, global construction firms have started adopting and have realized more benefits compared to the traditional surveying methods. Surveying specialists argue that the cost of adopting 3D laser scanning is prohibitive for small-medium tier companies. To solve this, many specialized service providers are already providing 3D laser scanning services as a niche service offering at an affordable cost within the industry. Small-medium tier companies can work with these service providers to realize potential benefits in their construction projects. In the future, 3D laser scanning technology will be used in conjunction with 3D printers for building construction, resulting in both cost savings and improved project schedules.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe