Managing Indirect Spend Categories Analysis – Indirect Procurement

Most procurement organizations spend a lot of time focusing on the goods and services directly related to the business and not on the indirect sourcing parts. Unfortunately, sometimes, few indirect operations such as IT, facilities, maintenance (MRO), human resource, marketing, etc. do not get sufficient attention. These indirect expenses account for around 35-45 percent of a company's overall spend and vary with the type of business.

Indirect spend, which is supposed to have a secondary focus, has become a major complication for most of the category managers, in every organization. Most organizations still consider cost reduction above process improvement or value addition. But the question still remains: Is it appropriate for the business in the long run? There is no doubt that optimizing indirect procurement could result in considerable savings; however, understanding the right approach to execute this is more important.

Many studies and practical executions conclude that category optimization for indirect spend can result in significant cost reduction and savings of 20–30 percent; sometimes, this can be as high as 40 percent for some spend categories. However, are these savings sustainable? The actual problem starts after a few years, when the tangibility of savings dries up. Cost reduction opportunities starts decreasing as most of the larger spend categories have already been reviewed and negotiated multiple times.

Direct vs. Indirect Spend Category:

Unlike direct expenditures, indirect spend owing to the nature of product or service requires a more varied and extended supplier base. It poses an inherent challenge for the category managers in developing, maintaining, and managing a larger number of suppliers. Measuring and tracking performances of such large-scale suppliers, deciding on the right set of KPIs, drawing inferences, etc. becomes extremely complicated.

In direct sourcing, it takes years to bring in new innovations, technology advancement, process improvement, etc. Companies have to invest in these innovations to remain competitive in the market. Costs tend to increase because of these investments. Consequently, there is always a time gap between cost reduction activities, at least by a few years. Due to this investment and cost reduction cycle, direct sourcing divisions can continuously generate savings and help improve the added value of their product or service. However, all such activities are less significant in indirect sourcing; management does not pay much heed to investments or is not interested in paying more for services that are less significant to the bottom line.

Challenges in Indirect Sourcing:

Many companies may have optimized every cent spent with direct suppliers, implemented various operational principles (such as Lean Six Sigma) to its limits in their manufacturing operations, and tightened the supply and delivery timelines down to the hour. Indirect spend presents even more complex challenges in opportunities for increased efficiency and cost control.

The following are the telling features of indirect sourcing, which makes their management all the more difficult and complex:

- Low Average Spends: The product volume is generally on the lower side because of the wide assortment of product and service categories and their suppliers. Therefore, procurement is unable to dictate terms in negotiations with suppliers.

- Frequent low-volume Purchases: The sheer volume and frequency of purchases, albeit of small individual values, makes indirect sourcing difficult and resource-intensive to handle.

- Uncontrolled/ Un-negotiated Spend: Every company understands the value of robust management of direct spends, but may not realize the value of managing their indirect spend. The fact is cost savings for indirect procurement is not linked to a specific bill of materials, as with direct procurement. Most of the times, the impact of cost savings in indirect procurement is underestimated by management.

Also counted as maverick spend, these purchases are not covered by a procurement-negotiated contract. This could simply be a one-time purchase of office supplies, or travel expenditures, or expenditure on critical ad hoc technical troubleshooting services.

- Driven More by Internal Stakeholders: Unlike in direct spending, Procurement has less of a say in matters concerning indirect spending as it affects all internal stakeholders. Therefore, it is difficult for the procurement function to control indirect spending

- Difficult to Evaluate: It is difficult to measure the quality of indirect goods and services as there is no definitive parameter to measure. In some cases, delivery of indirect goods and services is not registered within a company’s Enterprise system. Metrics typically applied to direct suppliers are not applicable when it comes to indirect suppliers.

- Requires Diverse Experience: Purchases can include items ranging from paper clips to catering, facility management, and electricity supply. Such a broad spread of purchase categories requires the procurement team to gain expertise in a wider range of products and services to procure effectively.

New-age Indirect Spending: Key Strategies to Curb Indirect Spending:

Measuring return on investment on most of the indirect spend categories is often difficult and ambiguous. Hence, the impact of indirect spends categories on the bottom line of any organization is uncertain. However, for direct spend categories, the impact of investment is directly visible on the business, unlike the indirect spend categories. Therefore, management often misjudges the potential of managed indirect spend categories.

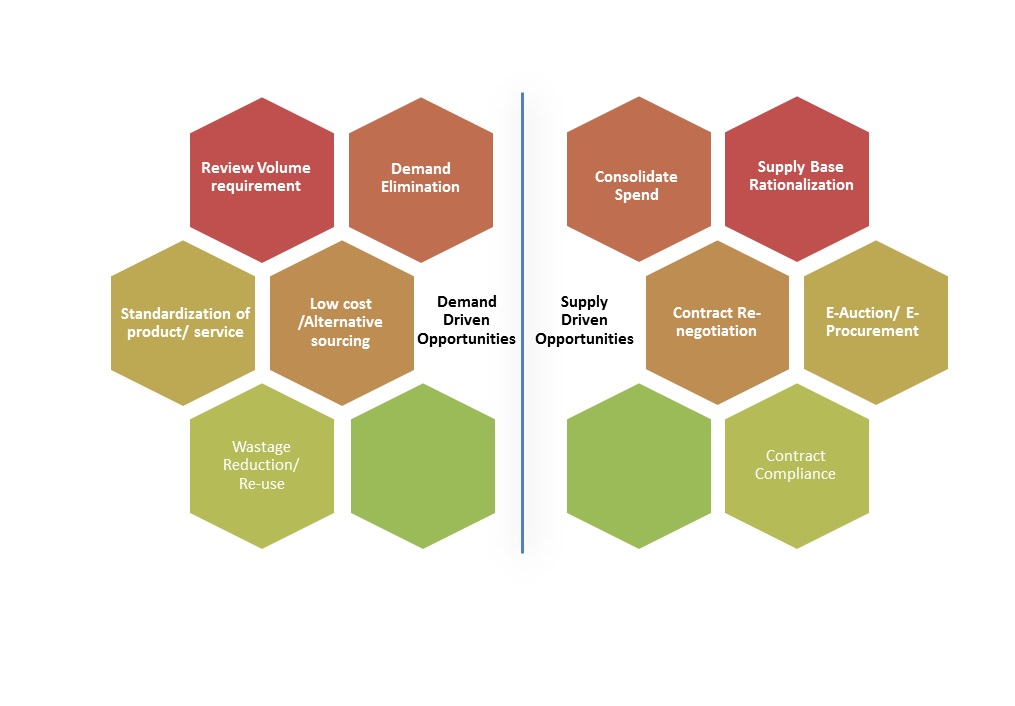

Procurement becomes overly complicated when large organizations deal with a diverse range of materials and services under indirect procurement category. Significant saving opportunities can be identified for both demand and supply driven organizations in a structured manner. Indirect spend do not always have a category-based strategy for sourcing, which leads to irregular sourcing. Because it includes low-value and low-risk products and services, the potential cost savings are overlooked by management

While managing indirect spend is challenging, the potential impact on the business makes the effort worthwhile. The impact might be indirect but it can significantly change business delivery.

There are some initial steps an organization can take to start bringing these expenditures under control:

a. Managed Spend, Use of Automation, and Measurement: The volume of transactions and diversity of suppliers make indirect spends an ideal area for management through collaboration tools.

Using the data that a company does have on indirect spend, prioritize areas with the largest spends; expertise should grow in these areas. Management has to redefine the mission of indirect sourcing. It should include not only cost reduction but also value creation by bringing new technologies into your company. Involvement of top management is crucial in such decisions.

Many existing solutions provide a number of ways to connect (web, EDI, SFTP), integrate with a variety of software and systems, allow closed loop procure-to-pay to minimize manual processes, and provide proper tracker for each spend.

b. Choose Preferred Suppliers: Onus should be on minimizing maverick spends by negotiating contracts with key suppliers in each of the top expenditure areas. By pooling the smaller spends into a fund with fewer suppliers, increased leverage on pricing can be achieved.

c. Set generic KPIs: Supplier capability measurement and evaluation for indirect suppliers are challenging owing to the variety of supplied goods and services and types of vendors. However, few generic KPIs could be used across a variety of vendors, including contract compliance, customer satisfaction, and cost competitiveness, and continuous improvement.

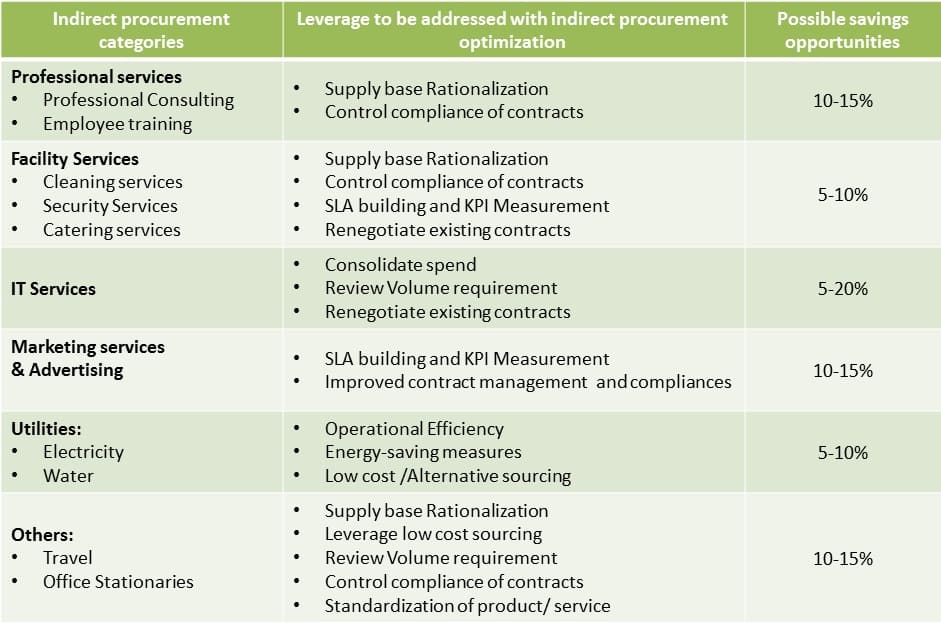

Many studies and experts from industry suggest following cost saving opportunities from indirect procurement areas, which constitutes a large chunk for most of the organizations:

Transformational Way Out:

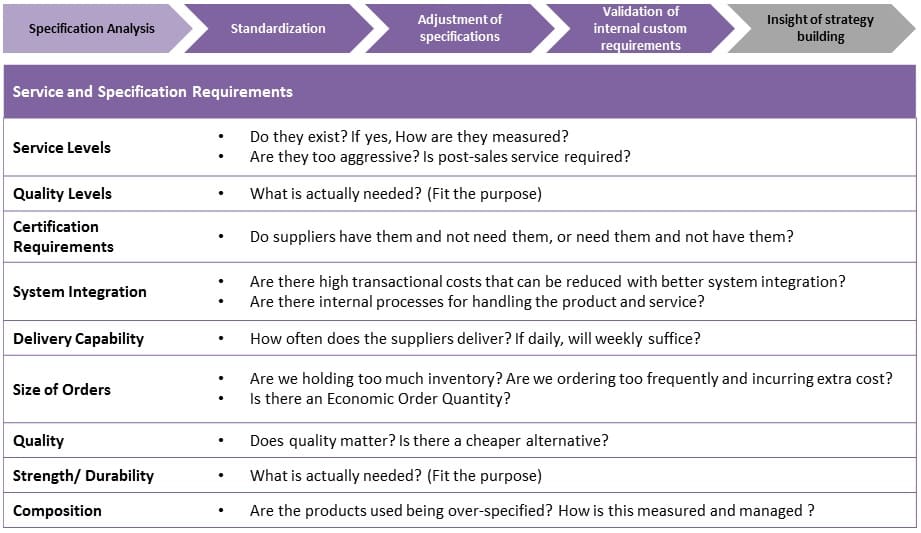

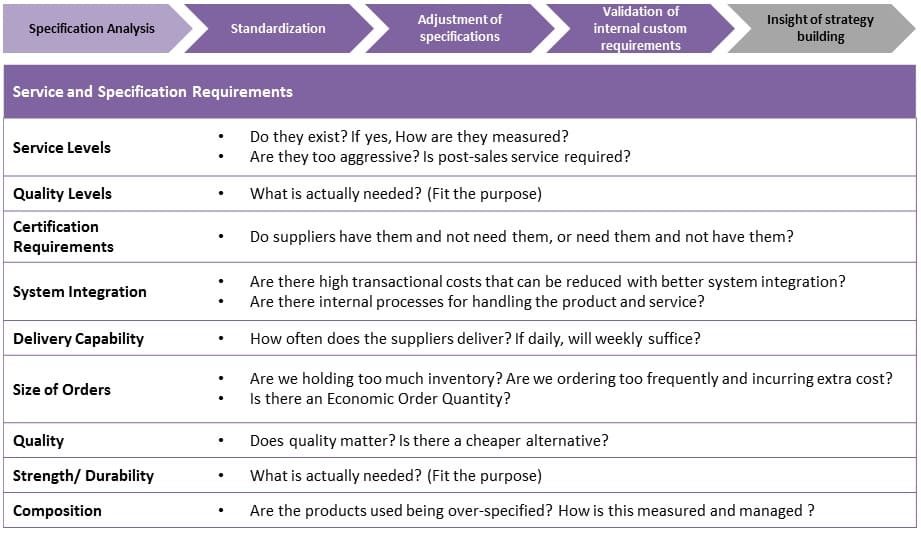

The following are the basic information that procurement might gather from the business to define requirements and specifications for identifying sourcing opportunities. Whether the current service and specification requirements are well defined needs to be evaluated.

Proper understanding of the current service & specification requirements can help in creating value from the internal supply chain.

Following are few more considerations for better opportunity realization:

1. Building a Leaner and Sustainable Sourcing Framework:

Completely analyzing the value chain and identifying the opportunities for adopting sustainable sourcing is crucial; it will help organizations in finding economical solutions. Various sustainability models can be adopted; however, leaner and simpler models are considered efficient and effective in sustainable procurement. While understanding the market, the organization should also understand the potential of reaping benefits at present and in the long-term. Basically, this will ensure that a right direction is set.

In the second step, a right solution needs to be designed so that the service delivery and buyer requirements are sustainably addressed. Right suppliers will be identified and audits will be performed in the third step to ensure that they adhere to the set standards. These audits are generally costly and organizations are often unable to find the right suppliers. Fourth step would be to enter into sourcing contracts with selected suppliers. Continuous monitoring and process improvement is done in the final step.

2. Choosing the Right Strategic Partner:

Due to strategic importance of the category and competitive market pressure, suppliers are clubbed into different groups. Ideally, supplier management should be based on the value and importance of the category in consideration. The major enablers for strategic relation with suppliers are high business growth, supply chain resiliency, and value chain optimization.

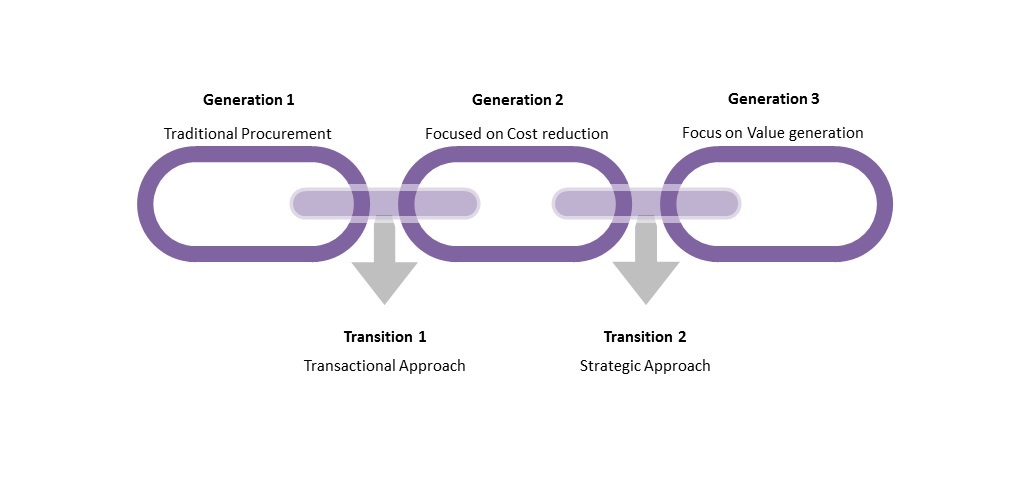

It is important for a company to realize which stage of procurement maturity they belong to. One should understand that Strategic SRM should not be implemented at a wrong stage. It is also equally important to understand the drivers for implementing Strategic SRM. It can be either a matter of choice or compulsion because of external competitive pressure for identifying the strategic supplier. Strategic supplier(s) is a subset of the key supplier base that companies collaborate with at an early stage in the value chain. Following this, a critical step is to align internal procurement objectives and KPIs with that of the strategic partner, such as measuring and benchmarking procurement performance process, and building robust contract management and supplier performance systems; this provides a strong foundation for a sustainable relationship. A continuous plan involving a consistent process, proactive initiation for innovation, and coordinated processes at various levels of the procurement organization will ensure the success of the Strategic SRM relationship.

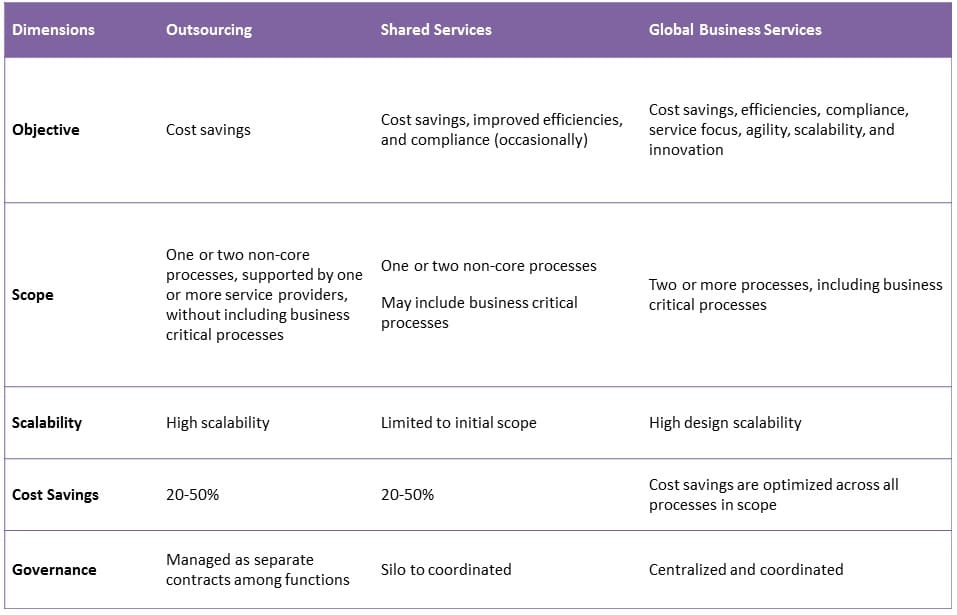

3. Shifting Toward Shared Services:

Shared services provide platform for consolidation and standardization of business data, which in turn provides immense capabilities for driving quality and success; cost reduction remains important and savings keep accruing.

The concept of shared services took form owing to the ever-growing need for cost reduction and standardization, based on the transactional activities of large-sized organizations. The idea is to support operations on a seamless, scalable, and sustainable trajectory of excellence. Compliance and controlled governance are all dependent on the expertise in process re-engineering and design capabilities.

Steps to Exploit Indirect Procurement to Reap Possible Cost Saving Benefits:

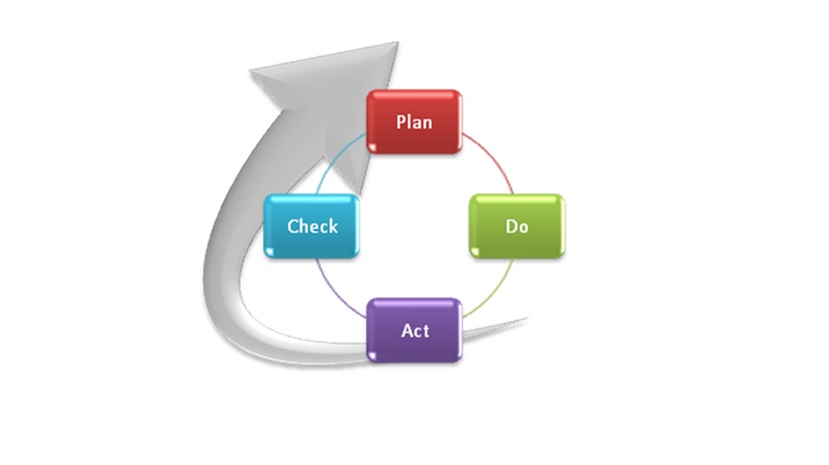

A structured approach is required to acquire savings out of indirect spending. This would require identifying areas with significant saving opportunities and chalking out an action plan to accrue savings in the long run. Managers need to adopt a very fundamental approach with the PDAC (Plan, Do, Act, Check) concept.

For successful implementation of any strategy, planning phase should be given the utmost importance. A major hindrance in indirect sourcing is the variety of areas where spend occurs. Therefore, a study is essential to recognize category, amount, and suppliers for each spend; this is necessary for identifying the saving opportunities before any action plan is taken up. It is essential to accentuate possible saving opportunities; significant saving opportunities, which generally tend to be demand- driven, need to be identified. Then, each opportunity should be prioritized based on possible financial benefits and the ease of implementing the steps that each opportunity warrants.

Then, an action plan involving both the procurement function and the budget owners from every department should be implemented to acquaint everyone across the organization with the goals and responsibilities of the indirect procurement cost saving initiative. The plan should influence every department in changing their budget utilization, to take advantage of saving opportunities in each spending area. Control measures, such as reducing the budget to reflect savings and invoking penalties for spending in identified problem areas, would help in ensuring that the initiative is adhered to.

Moreover, a system should to be implemented to periodically review savings in the revised procurement plan. This calls for a continuous effort in recommending departments about improvement areas and possible amendments in the revised procurement process.

Conclusion:

The focus on indirect sourcing should shift from mere cost reduction to value creation for internal stakeholders and organizations of all scales. The sourcing and purchase function has the ability to capture the essence of new trends, new technologies, and innovations to help management in making an informed decision. To ensure alignment with these values, indirect procurement strategies should be based on facts and data analysis to drive decisions. Many organizations use scenario and contingency planning as part of their strategy to ensure they have good sourcing plans in place. The above mentioned values govern everything done in indirect procurement. Again, this goes back and forth, between bringing innovations into the organization and putting them into competition to reduce costs. Therefore, management should strive for 360-degree excellence and not just cost savings.

References:

W. Whiffler and Dr. M. Jackson. “Indirect Procurement Optimization Unlocking areas of savings and value creation”, EY, Indirect Spend Thought Leadership, 2014.

Godfrey Huguley. “4 Key Strategies for Wrangling your Indirect Spend”, Take Supply Chain, January 2014.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe

A

P