Interview: Strong Supplier Relationships Crucial for a Sustainable future

(Pic Courtesy: DS Smith)

DS Smith, a multinational packaging company headquartered in the UK, has a mission to collaborate with suppliers and establish circular strategies that span from design and production to recycling, in order to create eco-friendly packaging for the constantly evolving world.

By 2030, the company aims for all of its packaging to be recycled or reused. Additionally, DS Smith is determined to use packaging and recycling to enable the circular economy by replacing problem plastics, reducing customer carbon and eliminating consumer packaging waste.

The Procurement function, led by Chief Procurement Officer (CPO) Alex Jennings, plays a crucial role in accomplishing the company's goals by managing supplier relationships effectively. Their contribution is so significant that the company's 2022 annual report recognizes them for successfully mitigating an “unprecedented” increase in input costs. The size, scale, and proficiency of the procurement operations, coupled with long-term buying relationships for both recyclate and paper, provided a competitive edge during a highly volatile period.

Beroe had a conversation with Alex Jennings to comprehend the significance of managing supplier relationships in this post-crisis era. Although it may seem obvious, executing a Supplier Relationship Management (SRM) program on a day-to-day operational level is challenging. It was 9 a.m. in London when Alex received Beroe’s video call.

Consistency in Principles

As the world grapples with the challenges posed by the COVID-19 pandemic, supply chain bottlenecks, and geopolitical tensions, maintaining consistency in principles as a CPO is crucial. For Alex, a CPO who understands the importance of strong supplier relationships, it means managing supplier relationships with regard to delivery, innovation, sustainability, and cost management. According to him, recent crises have highlighted the importance of strong relationships in ensuring continuity of supply. True partnership, where suppliers and procurement work together to find solutions, is essential during a crisis, and traditional transactional relationships may not suffice.

"Both parties have a responsibility to manage costs, but it is also important to support suppliers in need to ensure a solvent supply base. As the crisis subsides, costs may fluctuate, but the principles of partnership and sustainability must remain a priority," says Alex, emphasizing the importance of upholding principles and not reverting to an adversarial transactional relationship after a crisis.

When asked how the company's relationship with its suppliers was impacted by the intense period of supply chain disruptions, from the early days of the COVID-19 pandemic to the recent shortages and high prices up until six months ago, Alex said: “During this period, we have engaged in discussions with some of our suppliers to provide additional support beyond the contractual obligations. Despite the cost movements during this challenging period, we expect our suppliers to manage their costs effectively. The relationship between us and our suppliers is reciprocal; we agree to purchase from them while anticipating cost-efficiency, innovation, supply chain management, sustainability, and safety. However, when unforeseen circumstances occur there should be a recognition on both sides that one area of the relationship has changed. As we move beyond this crisis, the relationship will evolve further”.

He added that as businesses transition out of the crisis, there is pressure on all sides. “For instance, during the crisis, wood prices increased significantly, and when they eventually decrease, they should follow a similar pattern. Similarly, energy costs also rose but are now managed better and are declining. Both parties should recognize the changes in costs and expect them to stabilize eventually. However, the fundamentals of a partnership include building a sustainable supplier base, which necessitates profitability for investments in innovation, circular procurement, and sustainability. In addition, the supply chain must not include modern-day slavery or child labor. Therefore, it is vital to stick to principles and avoid reverting to an adversarial transactional relationship after the crisis ends. This approach will ensure that suppliers invest in critical areas that benefit all parties involved,” Alex explained.

Determine the Desired Outcome

For Alex, it is crucial to determine the desired outcomes of supplier relationships -- and segmentation helps in this regard.

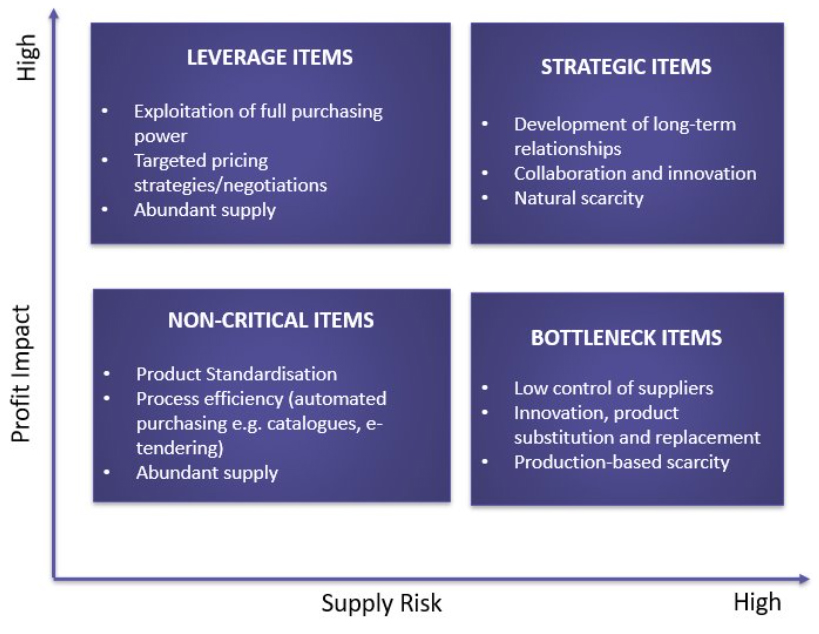

“We have a segmentation strategy to ensure that we differentiate between those with whom we need to collaborate on innovation, and those who provide a commodity that we can source from various sources, and it's more price-sensitive. Depending on the type of supplier, we employ different tactics to manage the relationship effectively. For strategic suppliers, we prioritize a safe and secure supply chain, while for commodity suppliers, we focus more on commercial considerations,” Alex said.

Kraljic Matrix supplier segmentation

Minimum standards must be established for suppliers based on the services and products they offer, as well as their ESG practices. Open-book costing can eliminate difficult pricing negotiations and ensure a fair margin for both parties. However, some products and services require a higher level of performance and capability, and negotiations should not be solely focused on price.

“Some elements are common across all suppliers and can be procured using tools like e-auctions, and the suppliers can decide how competitive they wish to be. However, we do not want to negotiate to a level that hinders the suppliers’ ability to invest because we have set ambitious goals for ESG activities as part of our purpose to redefine packaging for a changing world. Suppliers need to accompany us on this journey, and negotiating them to a point where they lose money does not align with our goal of achieving a safe and sustainable future for our company and our relationship,” Alex said.

He also believes that investing in suppliers is important for achieving ESG goals and redefining packaging for a sustainable future. It is crucial to maintain a balance between cost savings and supplier investment to achieve a safe and sustainable future for both parties.

Circular Procurement

The DS Smith team has set out to redesign their packaging to adapt to the changing world we live in.

They have established design principles that allow them to grade and score every design they create for their customers from a circular perspective. All 700 of the company’s designers have been trained in Circular Design Metrics, and they rank every package they design based on its circularity. Their goal is to remove problem plastics from their packaging, and they have already taken 520 million pieces off the shelves by changing their design approach.

Once they design and supply the product to their customers, the Procurement team’s responsibility is to pass those circular principles down to their supply base.

“Similar to Scope 3 emissions, we want our suppliers to work with us on how they can reuse and repurpose products. For instance, we want them to figure out how they can rework ink back into the process instead of throwing it away. We also want them to break down and repurpose materials like wood, rubber, and metal from their tooling after they have finished using them. We encourage our supply partners to set goals around design, quality of product, supply efficiency, cost management, cost improvement, innovation, and sustainability,” he explained.

Rewarding the Suppliers

DS Smith has launched a new Supplier Recognition Program to acknowledge the contributions and achievements of its suppliers. The program aims to recognize and reward suppliers who demonstrate excellence in innovation, sustainability, cost management, quality performance, and service. By setting targets for its suppliers and monitoring their performance against these criteria, DS Smith hopes to foster stronger relationships with its partners and drive innovation in the industry.

Alex said that the company refreshes and rebuilds its category plans every year, getting input from the business on supplier performance, innovation, and sustainability. The company determines the partners it wishes to grow and work with in the future and sets targets for its suppliers in areas such as cost improvement, quality improvement, supply performance, innovation, and sustainability. The category managers, along with the innovation team, monitor the performance of suppliers against each of these criteria.

The Supplier Recognition Program culminates in an awards ceremony later this year where DS Smith would recognize the best-performing suppliers in each of the categories and also present a “Supplier of the Year” award. The external recognition is a badge of honor for suppliers, giving them an entry into the industry and opening up new opportunities.

“This recognition is important and valued as it sets a standard in our industry, and winning it gives suppliers a reputation and an entry point in the market. Similar to the automotive industry, where satisfying Toyota and Nissan could pave the way for other customers, we want our suppliers to use our relationship to drive innovation, efficiency, and effectiveness in their product and delivery. This recognition will also serve as a development tool for our suppliers,” Alex explained.

He also notes that recognition is an essential component of any relationship, and the program aims to give external recognition to suppliers who go above and beyond the minimum expectations.

Never Waste a Good Crisis

As the conversation drew to a close, Alex reminisced about the past few years that were perhaps the toughest for all procurement and supply chain professionals across the globe.

“To begin with, I am extremely proud of how we handled the crisis. We were able to manage the situation due to the strong relationships we had built with our suppliers and our focus on business continuity planning. We took time to assess our supply chain and identify potential pinch points, ensuring we had alternative suppliers and the ability to react quickly when something happened.

“We did not let our customers down and continued to provide them with the products and services they needed to keep their operations running smoothly. We maintained daily, weekly, and monthly reviews of all categories and delegated authority to our team so they could take ownership of and fix problems. We believe in Extreme Ownership, meaning when someone owns a problem, they are responsible for fixing it. I believe these are the things we should be proud of from the crisis.

“Additionally, the crisis helped us to build engagement and identify areas where the function's enablement was breaking down. We focused on getting things done quickly during the crisis, which ultimately helped us work on cost improvement, cost reduction, and waste removal,” Alex concluded.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe

R

D