Interview: Why Emerging Supply Chain Technologies Initially Disappoint

(Pic Courtesy: ManMohan S. Sodhi)

The procurement-and-supply chain function is beginning to play a key role in all business areas, from analysis to long-term planning; therefore, the related technology space is witnessing rapid growth. Several start-ups are now catering to the procurement-and-supply chain function on the back of cutting-edge digital technologies -- such as AI, blockchain, and Internet-of-things (IoT) -- either to unlock new insights on data or to smooth out the processes.

However, procurement and supply chain professionals -- in general -- are not free from “buyer’s remorse” after implementing a new technology solution. An investment in new technology can lead to disappointment if it does not deliver the promised benefits.

Beroe spoke to Prof ManMohan S. Sodhi, Professor in Operations and Supply Chain Management at Bayes Business School (formerly known as Cass) at City, University of London, to find out why purchasing and supply chain professionals may be disappointed with the emerging supply chain technologies in the early adoption stages.

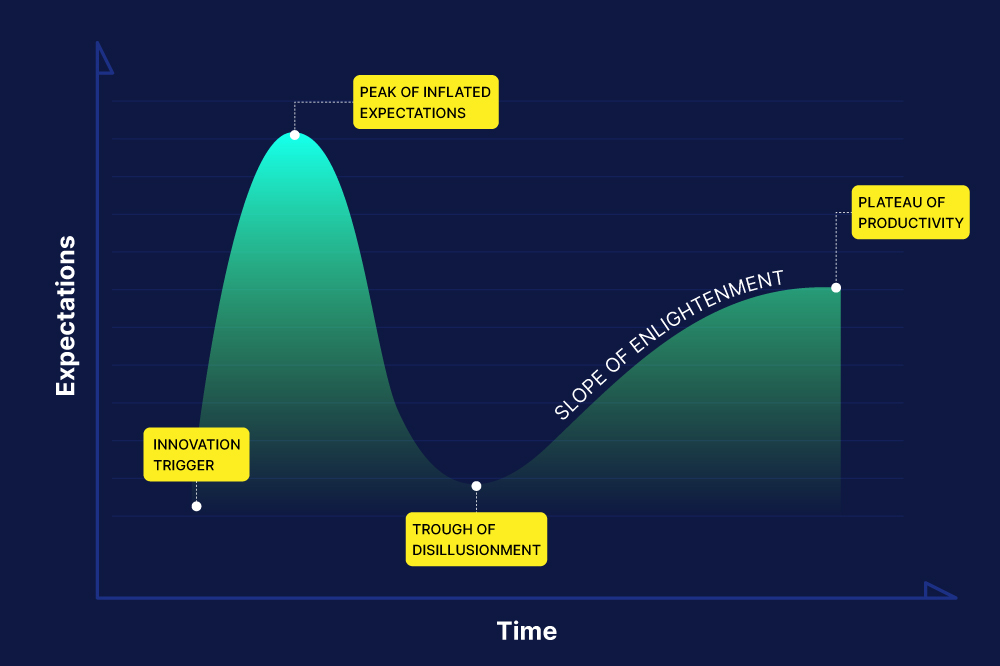

His research paper -- co-authored with Australia-based fellow researchers Zahra Seyedghorban, Hossein Tahernejad, and Danny Samson -- recently published in a top-tier peer-reviewed journal investigates supply chain professionals’ experience with technology. The paper proposes an explanation to the “Gartner Hype Cycle” -- from advisory Gartner Group. It explains how supply chain (and other enterprise) technologies generate inflated expectations, followed by a trough of disappointment, before greater industry experience adds reality to expectations.

Gartner Hype Cycle expressing inflated expectations followed by disillusionment and the slow learning experience, eventually leading to productivity.

It was 5 PM in London when Prof Sodhi received Beroe’s video call. When questioned about what prompted him to work on this research, he said: “When a company does not benefit from an enterprise-technology implementation, it may lead to losses amounting to hundreds of millions of dollars. Hence, I was more than curious to figure out why this is happening”.

Sodhi said that in collaboration with CIPS (Chartered Institute of Procurement and Supply), his co-authors and him initially saw an opportunity to gauge organizations’ interest in emerging technologies for the supply chain. The researchers chose blockchain, Internet of Things (IoT), and artificial intelligence (AI), which Gartner and others have labeled as “emerging technologies” for the supply chain. In collaboration with CIPS, they surveyed over 400 supply chain managers to assess the benefits, organizational constraints, and goals that the respondents viewed as pertinent to their organizations’ supply chains for whichever of the three technologies they were implementing.

The theoretical understanding for an organization benefitting from any technology is that the benefits depend on both the technology’s nature and the organization’s own needs. A global chemical company may have different needs for AI or blockchain in its supply chain than a domestic auto components manufacturer. As such, organizations would prioritize the expected benefits -- as well as organizational constraints and goals -- differently for technologies because their supply chains are unique and the technologies are very distinctive. Thus -- based on theory -- the researchers expected that the survey respondents would prioritize the expected benefits differently for the three technologies: AI, blockchain, and IoT.

Starting with these expectations, Prof. Sodhi said, “When the survey results came in, we were amazed to see that, as a pool, people prioritized the benefits, goals, and constraints the same way for all three technologies. One possible explanation is that, irrespective of the technology -- whether it is the blockchain, or AI, or anything else -- the survey respondents looked at them as “silver bullets” that would solve all their basic supply chain problems. Hence, the prioritization of expected benefits by technology really reflected their own supply chain needs.

“Moreover, no matter how we sliced and diced the pool of respondents -- public versus private sector, small versus large companies, companies with domestic versus those with global supply chains -- the pools prioritized the benefits the same way for all three technologies,” Prof. Sodhi said.

“Therefore, it appears that when it comes to emerging technologies, supply chain professionals have the same expectation of benefits, irrespective of the sector or size of the company,” he added.

In short, people are looking to whether the emerging technology will solve their current supply chain problems rather than what the technology offers. This is another way of saying they do not yet understand what the emerging technology has to offer; therefore, the expected benefits are simply a reflection of their needs. Of course, any technology that looks like it is going to meet all needs is going to create inflated expectations, as the Gartner Hype Cycle reflects.

In reality, emerging technologies will likely not meet all supply chain needs when implemented. Hence, as implementations drag on with no sign of meeting primary needs, there is going to be a trough of deep disappointment in the company, which is the second stage of the Gartner Hype Cycle.

“The research shows that technology is not informing the goals, it is not informing the benefits that the company would get for its supply chain, and implementation considerations are not informed by the technology’s nature. Blockchain, AI, and IoT are very different technologies -- yet people have the same expectations of all to solve all their current supply chain problems. Disillusionment sets in when inflated expectations are not matched post-implementation,” Sodhi explained.

He added that people approach emerging technologies as if they were implementing ERP or CRM -- they typically look at training costs, implementation costs, etc: “the laundry list of things is exactly the same regardless of the technology”.

Technology characteristics of some emerging technologies for the supply chain:

|

Blockchain |

IoT |

AI |

|

Characteristics |

||

|

Information aggregation; information decentralization; information immutability; information perpetuity; disintermediated and trustless platform |

Autonomous device coordination; smarter sensing/ actuating; monitoring; storing; interpret information; digital connectivity; interactivity; telepresence; intelligence; convenience; security |

Operations automation; descriptive, predictive, and prescriptive analytics (e.g., demand planning and forecasting); creative directions; capacity to learn and improve; pattern discovery; data optimization |

|

Challenges |

||

|

Insecurity of execution; lack of standardization; inflexibility; obduracy; black-box effect; the oracle problem |

Lack of standardization; intangibility; high IT involvement; high perceived uncertainty; high perceived risk; privacy issues; scalability; interoperability |

Lack of standardization; requires a massive amount of existing data; data governance and ecosystem; potential for wrong decisions; knowledge acquisition bottlenecks; right analysis model; required analytical skills |

Source: ManMohan S. Sodhi et al. Production and Operations Management, published by Wiley Periodicals LLC.

Avoiding Pitfalls

It is tough for supply chain and procurement professionals to avoid the siren call of new, emerging solutions.

“There is a larger question as to why people fall for new and shiny things. People fall for a promise when they are meeting an unknown. You have your needs and if somebody promises to meet your need, it is natural that you will fall for it. And you will fall for it repeatedly -- that is because you are fully aware of what you need, but not at all regarding what the technology or the solution provider is offering in terms of benefits”.

As part of the research findings, Sodhi and his team formulated a table of priorities that showcases supply chain professionals’ needs from any emerging technology.

How supply chain professionals perceive their own supply chain needs -- and hence any emerging technology for the supply chain; each list is in decreasing priority

|

Organizational goals for implementing the technology |

Benefits expected from the technology (affordances) |

Organizational constraints in adopting the technology in the supply chain |

|

|

|

Source: ManMohan S. Sodhi et al. Production and Operations Management, published by Wiley Periodicals LLC.

“The first column in the table is the organization’s goals for any technology. The second one denotes the benefits that survey respondents want from any emerging technology -- it reflects their own needs, regardless of sector, size, or nature of the supply chain -- this column is critical. And the third column lists the constraints that the organization expects from any new implementation.

“Now, this table can be used positively or negatively. On the negative side, if I am a vendor, and if I know that you are running an extensive request for proposals (RFP) as a buyer, all that I must do is somehow weave in all of the keywords in the benefits column in my messaging, and there is a high chance you will be convinced.

“On the contrary, on the positive side, buyers of supply chain technology can use this table as a guide to evaluating the solutions -- item by line item in the table -- before making a technology purchase decision, thereby avoiding falling for the siren call. Of course, buyers can use this table as a ready reckoner for testing the new solution before buying it,” Sodhi said.

Test before Buy

Sodhi said it would be better if supply chain and procurement professionals requested the solution provider to build use cases to test the benefits listed in the table above. Testing before buying is an age-old principle, and it can help with a systemic evaluation in line with the table.

“Those benefits are an organization’s needs regardless of enterprise technologies -- AI, Blockchain, or ERP. You should request the solution provider to build a use case on a benefit, say, “real-time capability” or “transparency.” It all boils down to the list of benefits and mapping them with organization goals and expected constraints. If the use case or demo module addresses some of these benefits, then this informs decision-makers whether to invest in that solution or not,” Sodhi said.

Persistent Problems

On a more reflective note, Sodhi said that despite tremendous advancements in enterprise-wide technologies over the years, supply chain professionals continue to experience almost the same problems that existed 30 years ago -- including lack of visibility, operational efficiency, or return on investment.

“It is probably true for all enterprise technologies. It shows that complexity in the supply chain is the real driver of the continuing challenges with people and systems from different functions in an organization, or even across different organizations, needing to collaborate via a tech platform. Maybe as technology matures, it may solve many problems that supply chain professionals are experiencing today. However, as new complexities keep getting introduced, we need newer solutions, which in turn will create new complexities,” Sodhi concluded.

(To read the research paper in full, please click here: https://onlinelibrary.wiley.com/doi/full/10.1111/poms.13694)

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe