Truck platooning technology to benefit shippers in the transportation market

Abstract

This whitepaper helps shippers to understand the development of truck platooning technology in the European truck transportation market. It also helps to determine the level of social and operational benefits that a shipper would acquire, post implementation, in the coming years. The shippers would look to analyze the key considerations at internal and external levels in terms of adoption of truck platooning technology in the future.

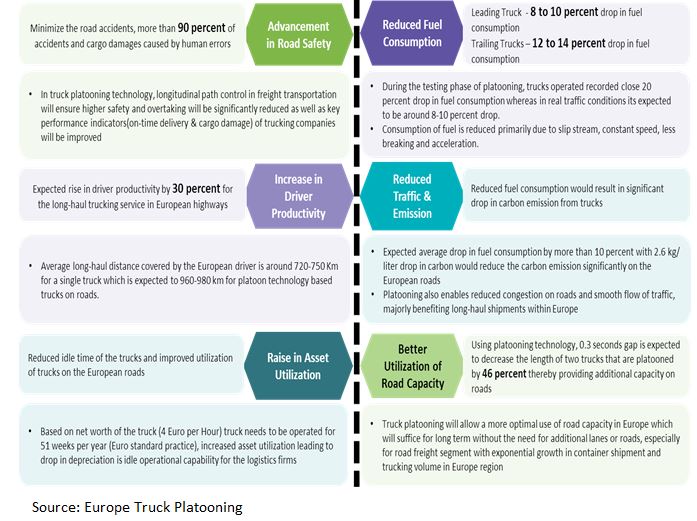

At present, the European road freight transportation is facing challenges of increasing driver wage, fuel consumption, drop in assets utilization, rising carbon emissions, and tight capacity. Truck platooning is expected to address all the major challenges for shippers and Logistics Service Providers (LSPs) for road freight category in the European market.

The objective of this paper is to highlight the current situation and development of truck platooning technology, cost elements that would benefit shippers and LSPs, business case scenarios tested during the truck platooning challenge in Western Europe. The estimated percent of cost-saving opportunity for pharmaceutical distribution, key business considerations along with the challenges and risk barriers are also discussed in the paper.

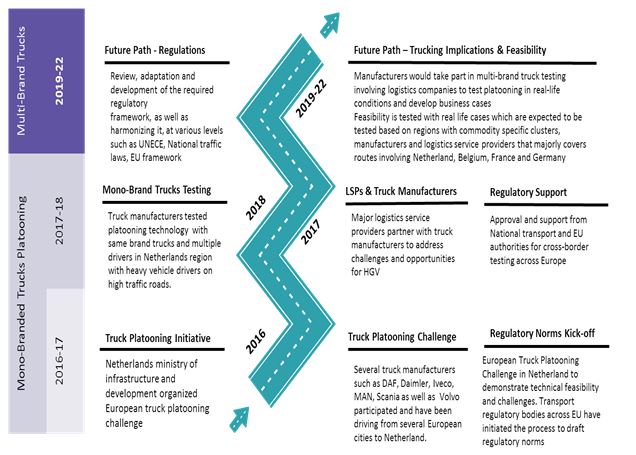

Roadmap of Trucking Platooning: Europe

A multi-phase implementation is highly critical for widespread adoption of platooning technology in the European road freight transportation, at a large scale, within the next five years. The roadmap of truck platooning technology elaborates the major development paths such as trucking regulations for cross-border transportation, stakeholders involved in platoon formation, and the level of automation involved in mono-brand and multi-brand trucks.

Source: Europe Truck Platooning

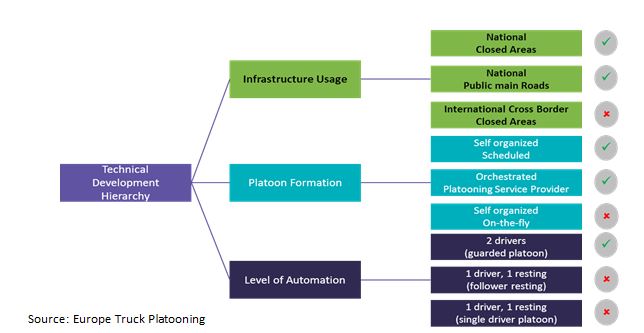

Development path for truck platooning technology

Stakeholders in the truck platooning value chain conducted a platooning challenge under various environments such as closed-area roads, covering ocean ports and airport terminals, self-scheduled connections, and trucks operated by two-driver-guarded platoons.

Gradually, multiple risks and challenges will be mitigated, based on technological and regulatory feasibility, conducted by truck manufacturers and LSPs.

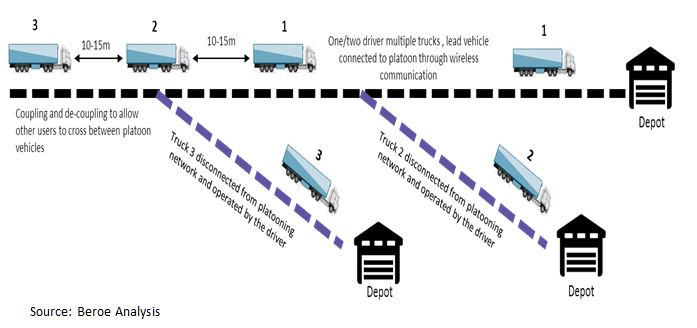

How truck platooning works?

Multiple trucks can be platooned only on highways; truck 1 is operated by driver 1, and trailing trucks are automated. However, trailing trucks are enabled with guarded platoon driver until approval from the regulatory bodies. Trailing trucks are platooned with aerodynamic force with driver in truck 1; platooned trucks are separated by 10-15 m/0.3 s and connected with wireless communication to transfer data.

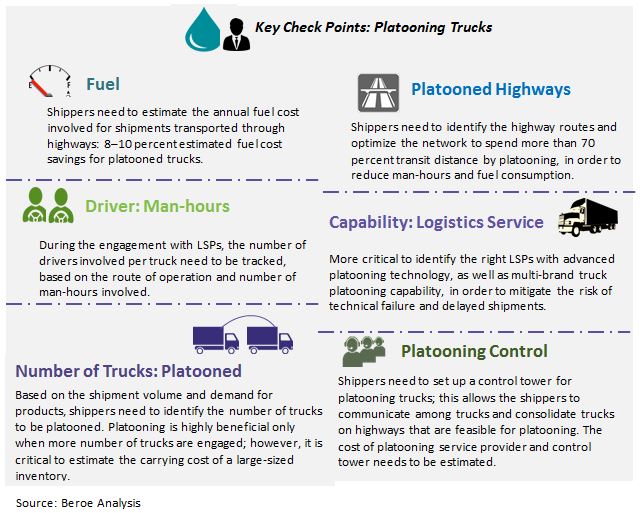

From the shipper’s point of view, it is critical to estimate the distance traveled by trucks on highways, which should be a minimum of 70 percent of the overall distance traveled, in order to achieve the benefits of truck platooning technology.

Truck platooning operation and social values

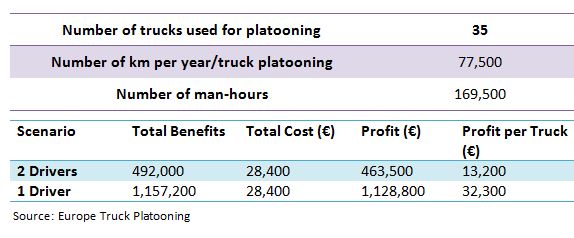

Business case analysis 1: Peter Appel transport

Transportation of shipments from DC-to-DC flows is an ideal situation for scheduled platooning. On one route that connects central DC and regional DC in 123 km, 70 percent of the distance can be platooned.

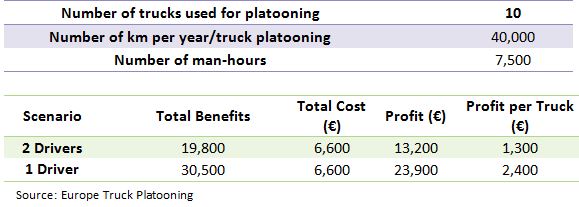

Business case analysis 2: De Winter logistics

This is an attractive scenario for truck platooning, as LSPs handle shipments of large volume in a single trip, with 200 km coverage on highway; hence, platooning can be formed on a large scale. In long-haul routes, trucking companies primarily operate with heavy trucks of tractor–trailer combination.

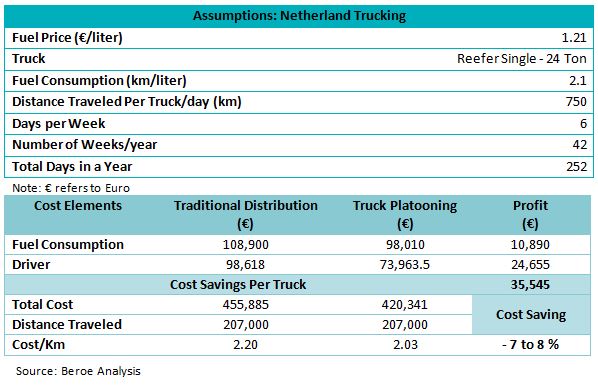

Real-time case analysis: Pharmaceutical distribution in Europe

Opportunities and considerations for truck platooning: Shipper’s perspective

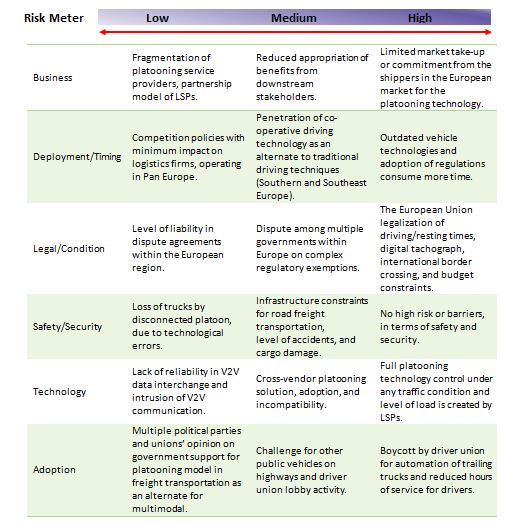

Deployment challenges and risk barriers

Source: Beroe Analysis

Conclusion

Truck platooning is close to the reach of shippers and LSPs in the next 4-5 years. The development process is in the right track in terms of regulatory support, partnership of LSPs and truck manufacturers, and technological feasibility on European highways.

From the shipper’s point of view, to capitalize on the benefits of truck platooning technology, it is important to develop a sourcing model. This model should connect shipment schedule, right-fit LSPs, volume and network optimization.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe