Zen and the art of Supplier Management

In collaboration with Ipsita Suman, Principal Analyst

The old proverb of “two heads being better than one,” holds special significance in the present business ecosystem, where organizations can no longer afford to operate in silos.

In the digital age, leveraging cross-functional networking and collaboration, is what powers businesses to transform. According to McKinsey,[1] “Networked enterprises were 50 percent more likely than their peers to have increased sales, higher profit margins, gain market share, and be a market leader.” Additionally, such highly networked enterprises operated as “learning organizations” where value was placed in interactions with others—within and outside the business.

Across industries, a robust trend points to establishing strong productive partnerships as critical to ensuring business productivity and continuity. In January 2017, Facebook announced its Journalism Project in collaboration with publishers such as The Washington Post and Vox Media. The collaborative effort, while helping Facebook recover from the negative image over the amount of fake stories appearing on the site, also potentially assist publishers in increasing subscriptions and newsletter sign-ups.[2]

Networking and collaboration add value to every business function -- including Procurement

Connected networks and collaborative partnerships can bring value to any business function -- including Procurement. Business functions such as engineering, HR, sales or marketing, being long acknowledged for their strategic role, are already using networking and collaboration to build symbiotic partnerships and gain cross-industry knowledge.

Procurement until recently, served the purpose of a transactional function focused on supply continuity and cost reduction. Now it is being viewed as a credible business contributor, driving strategic value across the supply chain. And to deliver this strategic value, sourcing teams need to collaborate and network with internal as well as external stakeholders.

However, a 2012 McKinsey survey[3] of more than 100 large global companies on supplier collaboration practices found that although over a third of the respondents said they collaborated with suppliers, fewer than 10 percent could demonstrate systematic efforts on supplier collaboration.

According to a more recent 2017 survey conducted by 3M, 70 percent[4] of the 237 suppliers interviewed pointed out that a majority of their customers lack strong models or practices to encourage collaboration, leading to a constant need for development improvements and a loss of efficiency. The findings reflect broad supplier sentiment and are not specific to 3M.

Supplier collaboration: key to success and innovation

In the 3M survey, 95 percent of the 237 suppliers surveyed across the U.S. reported as being, “at least somewhat empowered and encouraged to innovate and make suggestions for improvement for the customers they supply[5].” To tap into such authentic sources of knowledge, supplier collaboration and networking will have to feature as an integral part of the procurement function.

External collaboration with suppliers has the power to deliver immense value. At the same time, it is impossible to network or collaborate with thousands of suppliers.

In order to effectively collaborate with suppliers, procurement organizations can adopt the framework of Strategic Supplier Relationship Management (SSRM).

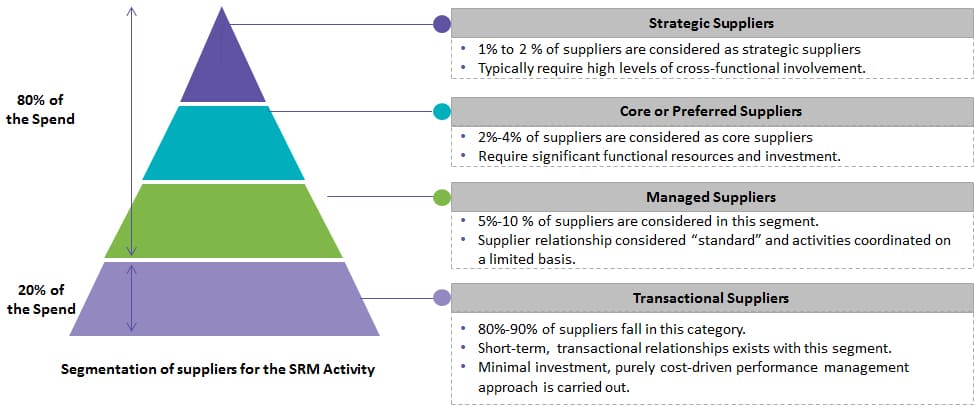

- Strategic partnership is generally made with High Critical High Value category suppliers who are core to the company. This 1 percent of supply base varies based on nature of business, complexity of category portfolio and procurement maturity.

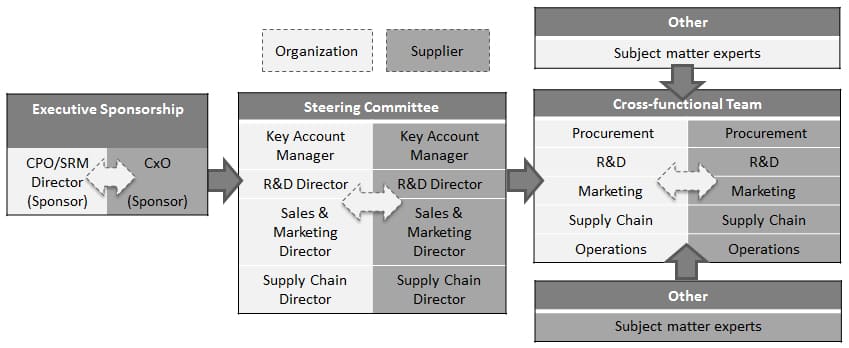

- Partnership Management involves establishing a Cross Functional Governance Team (C-Level) for the SRM program.

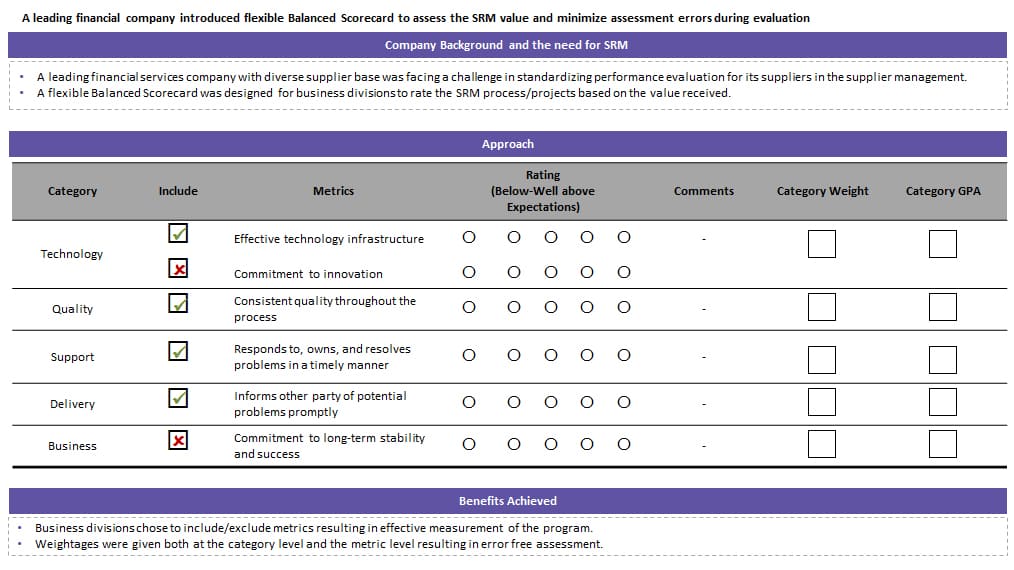

- Also, Unique Scorecard for each Strategic Supplier should be developed as the focus of the SRM would vary with different suppliers. Continuous Performance Evaluation and Reporting ensures that deviations and time overruns are checked on time.

Source: Expert Interaction, PwC

- The relationship framework involving Sponsors, Steering Committee, and a Cross-functional SRM team drives the relationship between the organization and a preferred supplier

- The level of involvement from top-level executives may vary depending upon the nature, size of the consulting project undertaken. For Example: Strategy and M&A consulting projects involve key executives more than any operational consulting projects

iPhone maker Apple offers a great example of tapping into supplier innovation. According to a report in Bloomberg News, the company is tapping into little-known suppliers that have spent years developing components in the hope they might one day enjoy widespread adoption.

Supplier Segmentation

On what basis do Procurement managers segment suppliers? The following questionnaire is one of the best approaches to take.

- Is the supplier relationship strategic to the business and important to business growth?

- Does the supplier support the most important products or services of the organization’s supply chain?

- Does the supplier represent a significant percentage of the total expenditure?

- How does the supplier impact company profitability?

- How does the supplier impact the overall quality of the product?

- What is the risk of supplier failure?

- How is the availability of substitute product/supplier?

- Are regulatory and security issues involved in the services provided by the supplier?

- What is the “Value-add” supplier provides to the finished product / service?

- Does the supplier offer specialized products or capabilities that offer a competitive advantage?

- What does the supply market look like: Is the supplier in a competitive vs. saturated market?

Best-In-Class companies consider high-potential suppliers for SRM programs and invest in them with the expectation that they will come up with innovations that add value in the long run.

Source: Hackett Group, Expert Interaction

Case Study

Source: Expert Interaction, Procurement Strategy Council research.

Networking and collaboration will create a unique competitive advantage

A Strategy& PwC report[6] titled, Next wave sourcing: Reinventing procurement to drive growth and profitability, stated that CPOs saw a tremendous untapped potential in collaborative supplier relationships. Forty-four percent of those surveyed saw the development of these partnerships as a top priority over the next five to 10 years.

Leaders and decision makers must understand that the integration of networking and collaboration into the procurement function is a critical lever that will drive growth and profitability. It also affords the opportunity to create new value -- a unique competitive advantage that companies can’t ignore.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe