Procurement organizations have the power to reduce greenhouse gas emissions

With inputs from Rajesh Kumar Subramaniam -- Research Analyst, and Shubhasheesh Singh -- Senior Domain Analyst

The Paris climate agreement, which was signed by governments around the world in December 2015, is a broad framework designed to cut down carbon emissions. As the deal approaches the two-year anniversary, the politics surrounding the climate debate has only gotten hotter.

The 2-degree Debate

When compared to average temperatures recorded during pre-industrial revolution, the Paris agreement envisages keeping global average temperature from rising 2 degree Celsius by cutting down on carbon emissions. The deal aims to limit the temperature increase to 1.5°C

Beyond 2 degrees, a section of scientists argue that the world risks catastrophic climate change in the form of higher seas, changes in rainfall patterns, food and water crises etc.

Early this year, U.S. President Donald Trump decided to pull the nation out of the Paris climate deal that created lot of uncertainty. To be sure, the exit process could take about four years, round about 2020. We need to wait and watch what sort of impact would this have on the pledge.

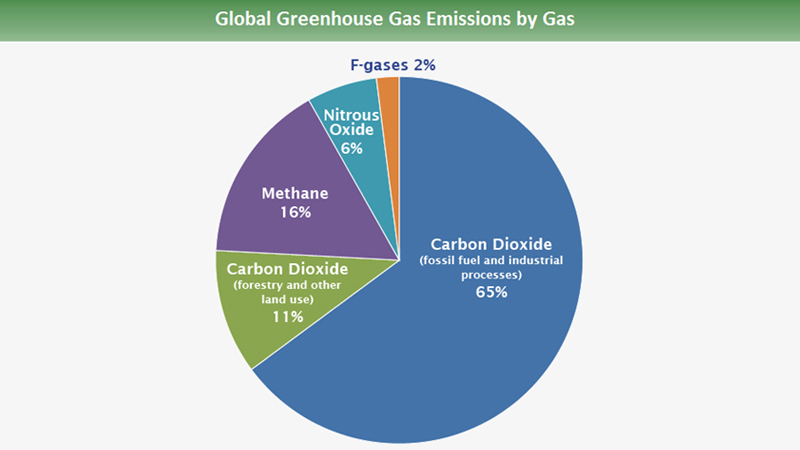

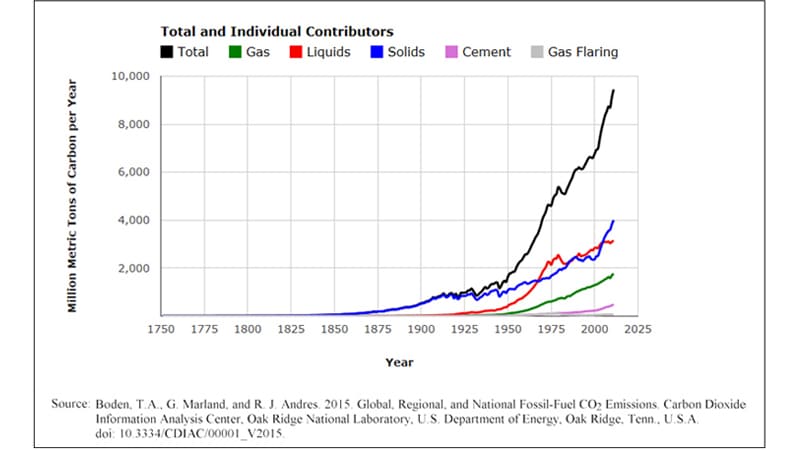

Since the year 1751 just over 400 billion metric tonnes of carbon have been released to the atmosphere from the consumption of fossil fuels and cement production, according to a report published by Carbon Dioxide Information Analysis Center (CDIAC). And half of these fossil-fuel CO2 emissions have occurred since the late 1980s.

Source: U.S. EPA

Role of Procurement in reducing emissions

Amidst all this debate, if one were to ask whether procurement organizations have a role to play in reducing the greenhouse gas emissions, the answer will be a resounding Yes!

Through sustainable procurement policies, sourcing managers are already playing a key role in reducing the carbon footprint.

Though the importance of sustainability is gaining visibility, the biggest question among the procurement teams is how to adopt such practices without taking a hit on the operating and net profit. There are different views in implementing these processes. Certain organizations view it as an extra burden to their balance sheet, whereas others view it as a competitive advantage.

Supplier evaluation

Finding a right supplier who could comply with sustainability practices is as important as setting the policy itself.

Three qualitative factors are crucial for any buyer-supplier relationship to be successful:

Synergy |

Choosing a supplier with same or positive caliber is vital for sustainable sourcing to be effective. This will help create the right synergy between the buyer and supplier |

Benchmarking |

Benchmarking in terms of improvement, sustainability certifications and periodical targets should be included as key parameters in assessment of the supplier. |

Process Improvement |

Working closely with the supplier is equally as important as choosing the supplier. Assess whether the supplier can adopt the technical know-how, which the buyer provides, or by an external consultant. |

Key challenges of implementing a Sustainable procurement programme

Irrespective of the outcome of the global climate deal, Procurement organizations have the power to usher in green initiatives across the supply chain. However, the task is not without challenges.

Some of the green procurement challenges that sourcing managers face are:

1) Ineffective supplier management

2) Lack of internal alignment

3) Lack of tools and techniques

4) High implementation cost and time

Supplier Management and Evaluation

Best-In-Class organizations consider Supplier Management as a key initiative towards implementing sustainability in the supply chain. Also, leading Fortune 500 organizations conduct Third Party Risk Assessment to objectively assess suppliers' sustainability standards.

Managing supplier evaluation process is a tedious task, especially when sourcing actitivities are done at a global level.

Moreover, as visibility towards supplier compliance reduces beyond the tier-1 suppliers, procurement organizations get caught in a blind spot. Supplier evaluation at frequent intervals is key to maintaining sustainability standards throughout the supply chain cycle.

Below is the difference in traditional and best-in-class supplier management approaches in maintaining sustainability standards.

|

Traditional Approach |

Best-in-Class Approach |

|

Sustainability Parameters are not considered explicitly in sourcing process

Suppliers are audited in response to a supply risk problems or based on their high risk profile Provides less training and guidance to suppliers on sustainability opportunities Supplier code of conduct address only key aspects and does not include exhaustive parameters to measure sustainability |

Sustainability scorecards is considered as an integral part of sourcing decisions Assesses all suppliers according to sustainability parameters and tracks supplier sustainability performance frequently either in-house or using a Third Party Risk Assessment Platform provider “Sustainability Meetings” are held regularly with key suppliers to encourage and improve on sustainability metrics Supplier code of conduct included with all sustainability metrics on which suppliers can be audited objectively |

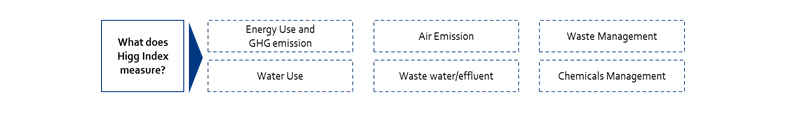

Many evaluation tools and techniques are deployed by procurement teams to evaluate supplier performance towards sustainability. For example, Apparel and Retail organizations utilize Higg Index in evaluating their supplier performance toward sustainability targets besides working with Third Party Risk Management firms such as Sedex, EcoVadis, Ecodesk, Cr360 etc.

Below is the brief about parameters used in Higg Index:

1. Higg Index consists of different modules with list of qualitative questions framed to measure social and environmental sustainability performance.

2. Higg Index modules assess product specific practices at Brand level, and assess facilities including materials for packaging etc.

3. Organizations receive scores by answering the modules and can benchmark themselves against the best practices followed at the industry level, and improve their sustainability practices.

Fair Factories Clearinghouse (FCC) is yet another database created by Reebok International Ltd, the National Retail Federation, Retail Council of Canada and World Monitors to create an online global database to share factory audit and compliance data.

Lack of Internal Alignment

One of the most persistent challenges to supply chain sustainability is the lack of internal alignment in an organization. This can have negative impact on supplier’s supply chain sustainability performance. For example, last minute changes in the requirement or changes in product quantity can create significant pressure on the suppliers, who would be forced to increase worker overtime schedules or adhoc sourcing from sub-contractors to meet buyer’s demand. This puts the entire supply chain at risk.

Sustainability strategies have to be integrated and closely coordinated with business strategies.

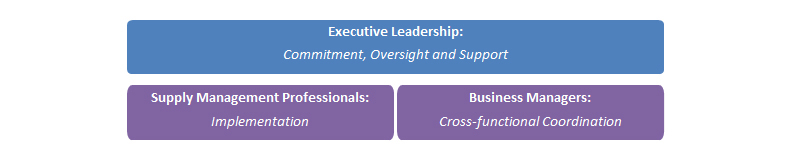

Key elements of internal responsibility for sustainability:

The executive leadership should drive the commitment toward sustainability, provide support and oversee the initiatives for better results. The key to the sustainability initiatives lies with the supply management professionals who implements the initiatives. Business managers facilitate the cross-functional coordination in sustainability initiatives to achieve greater results.

Contract Management plays a crucial role in facilitating procurement professionals to persuade suppliers to undergo audits and be compliant. Procurement organizations have to include requirements relating to supplier audits during contract renewal. This will help supply management professionals in identifying only those suppliers who are willing to submit audit certificates whenever required.

Case Examples

Despite the many challenges around implementing a successful sustainability sourcing program, Procurement organizations are working towards reducing greenhouse gas emissions across supply chains.

Here are some of the examples:

Industry: Personal Care; Spend Area: Packaging

1.) Personal care giants have announced major plans towards sustainable packaging.

|

Company |

Sustainability Goals |

Year |

|

|

Unilever |

100% plastic packaging components to either be recyclable or reusable by 2025 |

2017 |

|

|

P&G |

Replacing 25% of virgin resin by PCR in over 500 million bottles annually by 2018 |

2017 |

|

|

Body Shop |

Reduce around 70% petroleum based resin in the packaging by 2020 |

2016 |

|

|

J&J |

Increase recyclability of the packaging products to over 90% in key markets |

2015 |

|

|

Shiseido |

Switching to sugarcane derived plastic as preferred packaging format |

2014 |

|

|

Colgate Palmolive |

Committed to make 3 out of 4 packaging 100% recyclable by 2020 |

2014 |

|

Category: Fleet

2.) When a pharma company implemented green fleet program, users resisted low emission vehicles. In order to make the low emission vehicles attractive, the company introduced an incentive scheme for drivers by providing about $320 worth of green vouchers for John Lewis or similar higher brands for employees choosing vehicles with CO2 emission less than 115g/km. This helped drive user adoption rate and the company was able to reduce the overall CO2 emission average to 123g/km from 168g/km in five years.

Industry: Retail

3.) Walmart aims to reduce emissions in its own operations by 18 percent by 2025 (from 2015 levels), through increased energy efficiency, sourcing of renewable energy and and fleet efficiency.

The retail giant said it would work with suppliers to reduce emissions by 1 gigaton from the production and use of the products it sells between 2015 and 2030, equivalent to taking more than 211 million passenger vehicles off U.S. roads and highways for a year.

Conclusion

With increased consumer awareness and pressure from environmental policies, sourcing managers will begin to play a very prominent role in reducing greenhouse gas emissions from supply chains.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe