Getting the most out of your suppliers via Innovation

The Procurement team has already been involved in improving bottom-line savings, process, etc. Now, with changing business scenarios leading to New Product Development, Procurement is highly expected to bring about Innovation. As most of the companies have already exhausted internal innovative approaches, they are turning towards suppliers in order to bring about Innovation.

Procurement teams have been focusing on process and system improvements to bring about innovation and encourage savings. However, with most procurement teams moving swiftly into mature phases, the low-hanging fruits have already been plucked.

According to the Deloitte CPO Survey 2018, 58 percent of the procurement leaders are focused on new products, services, and market development. Hence, Procurement’s role is changing from mere Cost Reduction to Innovation. Collaboration and Cooperation with key suppliers can help bring about Innovation and lead to the lowering of the Supply Chain Risk.

Below are the key drivers of Supplier Innovation

Supply Chain Cost

- The demand for high quality products at lower cost increases the pressure to come up with innovative ideas to decrease cost.

- There is cost pressure across the supply chain, and it is not limited to the product.

Market Agility

- Faster new product introduction (NPI) and a reduction in the time taken to realize profits

- Formulating new supply channels and collaborations with suppliers to serve customers better

Technology

- Technology revamp of supply chain requires increased supplier engagement.

- Better technology enables greater supplier engagement and hence, provides opportunities to innovate.

IP Protection

- Intellectual property threatened in modern day competition

- Increase trust with suppliers to preserve IP and help them file new IPs

Proposed Solutions

- Best In Class organizations use a combination of approaches to encourage Supplier Innovation in different scenarios.

- It has been observed that organizations are able to maintain better relationships and negotiate better rates and payment terms with suppliers engaged in innovation.

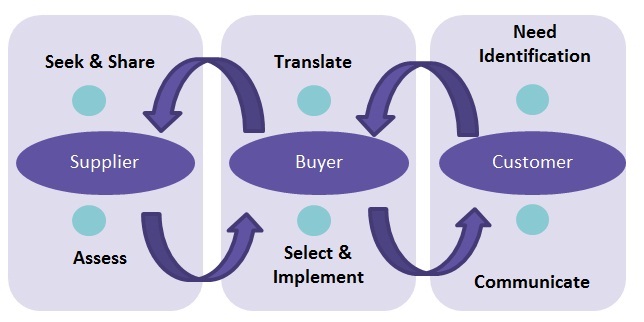

Steps involved in a systematic innovation process

- Need Identification: Companies must understand the needs of the customer to communicate them to the suitable supply base.

- Translate: Companies must translate the customer needs into tangible specifications to set focus for the suppliers.

- Seek & Share: Companies have to reach out to the relevant base of suppliers and share the customer’s need in the form of tangible specifications.

- Assess: Companies must have the engaged suppliers in a transparent environment where the sharing of benefits is clear.

- Select & Implement: Feasible ideas must be selected and guided by the company in a suitable infrastructure.

- Communicate: Companies must efficiently communicate the success of the innovation with the customers to review the actual benefits achieved.

Innovation Models and Industry Case Examples

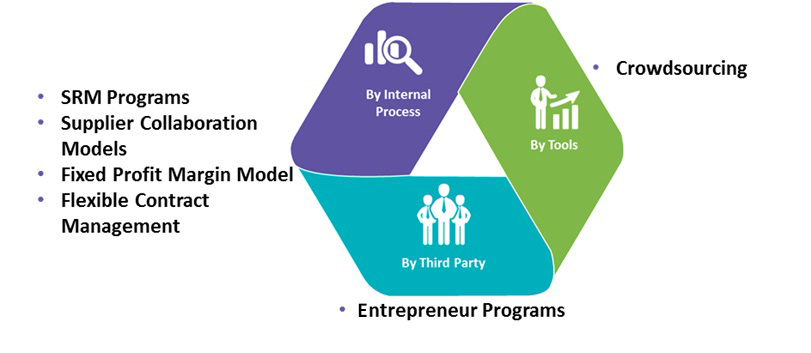

There are three different approaches to Supplier Innovation.

The People – Process – Tool methodology helps a company identify an area of approach for Supplier Innovation.

Best In Class companies usually start with the Process approach, which is deploying SRM programs, Collaboration models, Fixed Profit, and Flexible Contract model. This is because these approaches can be managed and handled without the supervision of a third party or tool.

Case 1: Via Process – SRM Programs

The Procurement Organization conducts various SRM programs such as R&D collaboration, strategy discussions, ‘Supplier Innovation events,’ etc. to drive innovation among suppliers.

Case Example

|

Company |

Innovation Strategy |

Approach |

|

Large CPG company |

|

|

|

Large F&B company |

|

|

Case 2: Via Process – Supplier Collaboration Models

Procurement Organization chooses to work with single or multiple suppliers on a specific goal such as inventory reduction and collaborates effectively with suppliers, thereby driving innovation.

Case Example

|

Model |

Description |

Industry Example |

|

Partnership model |

|

|

|

Co-development model |

|

|

|

Collaboration |

|

|

|

Joint Business Plan |

|

|

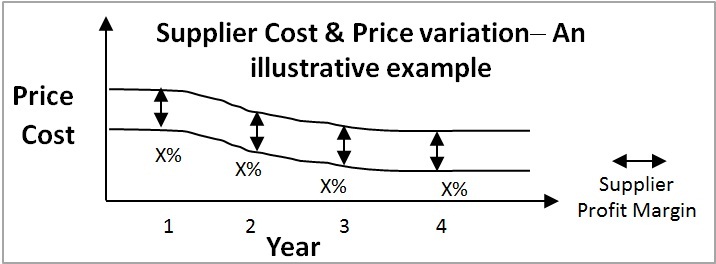

Case 3: Via Process – Fixed Profit Margin Model

The Procurement Organization follows ‘fixed profit margin’ with suppliers, thereby ensuring profitability for suppliers, and it demands innovative solutions on cost reduction, quality improvement, etc.

Case Example

Business Case: Accessing Innovation through Fixed Profit Margin Model

A fixed profit margin in the innovative commercial model encouraged the suppliers to come up with innovative solutions to cut production cost and optimize company’s spend.

|

Business Case |

|

|

Challenges |

|

| Approach | |

|

|

|

| Benifits Achieved |

|

Case 4: Via Process – Flexible Contract Management -

The Procurement Organization realizes cost saving opportunities by providing more flexibility to suppliers through an innovative contract management process.

Case Example

Business Case: Accessing Innovation through Flexible Contract Management

Companies could realize cost-saving opportunities by providing more flexibility to suppliers through an innovative contract management process.

|

Business Case |

|

|

Challenges |

|

|

Approach |

|

|

Benefits achieved |

|

Once companies exhaust these models, they go for the Tool approach to bring about Supplier Innovation.

Via Tools: Crowdsourcing

Crowdsourcing is a technique used for gathering ideas from multiple sources such as subject matter experts, consumers, suppliers, employees, and stakeholders of companies.

Case Example –

Business Case: Accessing Innovation using ‘Crowd sourcing’

Crowd sourcing technique served as a platform for multiple suppliers to come up with innovative ideas in a short span of time, and subject matter experts on the platform facilitated the conversion of raw ideas into feasible business plans.

|

Business Case |

|

A FTSE100 UK-based electricity and utility company with thousands of suppliers across the globe was looking for solutions for its critical projects such as repairing ageing pipes without digging, inspecting live pipe-crossings across railways and rivers, etc. |

|

Challenges |

|

The company‘s key suppliers were present across the globe which put more challenges for the company in terms of finding solutions quickly. Suppliers had raw ideas, but those ideas could not be converted into feasible business plans. |

| Approach |

|

The company decided to deploy crowdsourcing technique to effectively channelize the supplier’s ideas and convert them into an actionable business plan. - Each supplier posted their ideas using the crowdsourcing platform. - The ideas were channelized through industry experts, and selective ideas were screened thoroughly and shaped into business plans. Industry experts helped the suppliers in converting their raw ideas into business plans. The company came up with awards and monetary benefits which motivated more suppliers to come up with multiple ideas for the challenges posed by the company. |

|

Benefits achieved |

|

The company managed to find new innovative suppliers across categories. In less than three months, more than twenty-three challenges posted by the company was successfully fulfilled with innovative solutions The process encouraged the participation of more than a thousand suppliers. |

Bringing about Supplier Innovation via People/ Third Party is the latest approach which companies are using.

Via People: Third Party Entrepreneur programs

Third Party firms help in driving innovation through workshops and coaching sessions. Both suppliers and buyers participate in these programs in order to bring about innovation.

Case Example

About the organization: Agropur Cooperative is a leading North American dairy firm founded in 1938. With sales of $5.9 billion in 2015, the Cooperative is a source of pride to its 3,367 members and 8,000 employees. Agropur processes more than 5.7 billion liters of milk per year at its 39 plants across North America. It also boasts an impressive roster of brands and products including Natrel, Québon, OKA, Farmers, Agropur Signature, Agropur Grand Cheddar, Island Farms, BiPro, and the Ultima Foods joint venture’s iögo and Olympic brands.

Ongoing Business Case - Agropur Cooperative, in partnership with the Quartier de l’innovation de Montréal, AgBioCentre, and NineSigma, have announced the launch of Inno Challenge, an initiative to create new dairy products through open innovation.

Agropur’s ‘Together, Let’s Reinvent Dairy’ challenge seeks to identify impactful new innovations that expand, sustain, and reinvigorate the use of dairy products and elevate dairy beyond its status as a household staple. The results of their efforts will be presented at Agropur’s Inno Expo.

Innovation Partner- The Quartier de l’innovation (QI) is an innovation ecosystem in the heart of Montreal that aims to boost the city’s potential for creativity. QI draws on the complementary resources of its numerous partners in research, training, innovation, and entrepreneurship to create concrete projects.

Supplier benefits - Up to four projects will each receive a grant of up to $25,000 and access to Agropur’s innovation support resources. Agropur will work with them to co-develop the selected concepts and bring them to the prototype stage.

Conclusion

Best In Class organizations use a combination of approaches to bring about Supplier Innovation in various scenarios. Procurement can exploit the People-Process–System approach in order to bring about a holistic development in Innovative strategies.

For new product development and R&D collaboration (mostly Direct categories), companies usually go for the process based Supplier Innovation approach.

However, there is a trend of Tool based and People based approaches also for Direct category Supplier Innovation. Supplier Innovation is relatively low in Indirect categories.

It has also been observed that organizations are able to maintain better relationships and negotiate better rates and payment terms with the suppliers engaged in Supplier Innovation programs.

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe