Trade war or not: C-Suite expects Procurement to take lead in supply chain risk

The latest buzz word is disruption to world trade with the latest episode involving U.S. and China threatening to impose tariffs on billions of dollars’ worth of goods and services that flow between these two giant economies.

However, all is not lost yet. As per a latest report by the Wall Street Journal, China likely will offer to import more U.S. goods during negotiations that are expected to take place in the third week of May in Washington.

China is negotiating as part of a U.S. proposal to levy tariffs on $50 billion in Chinese goods ends. The U.S. is also threatening tariffs on another $100 billion on Chinese goods as part of the same dispute. China has also responded in kind by proposing to impose tariffs on U.S. goods, including its famed agricultural exports.

Procurement Organizations will be invariably get caught in a trade war as it would disrupt supply chains across the globe. In fact, the Beroe LiVE community of procurement professionals had voiced their topmost worry last year: Fifty five percent of those who were surveyed said that they are worried about global squabble over free trade. And their worry is coming true as trade is increasingly getting caught in the crossfire of geopolitics.

Meanwhile, in a survey of around 2,000 chief procurement officers (CPOs) at more than 300 organizations, consulting firm AT Kearney and financial analysis company RapidRatings found that 78 percent of the respondents said they expect their procurement teams to take a larger role in managing risk in the next two years.

Based on existing geopolitical and financial risks, procurement leaders prioritize risk management as one of their most strategic responsibilities, the report showed.

The C-Suite has higher expectations for Procurement to manage supply chain risks and 90 percent of procurement leaders have said they are routinely involved in corporate risk management initiatives. However, only 30 percent of other Procurement teams who are not in a leadership role are involved in corporate risk management initiatives, according to the report.

This shows growing importance of Procurement teams in managing supply chain risk for their organizations.

In its Global Risk Report for 2017 prepared by the World Economic Forum, Walter Quattrociocchi of Northeastern University highlights the danger of fake news or false information.

“Social media’s power to misinform, manipulate and distort public opinion has become severe. Experimental evidence shows that confirmatory information is accepted even if it contains deliberately false claims, while dissenting information is mainly ignored or might even increase group polarization,” Quattrociocchi said.

Access to reliable information is the key to an effective as well as robust risk management practice. And there exists a danger of getting caught up in a web of misinformation or self-fulfilling echo chambers. This was evident when pollsters and mainstream media failed to accurately predict the outcome of Brexit vote and U.S. presidential elections. Such are the challenges posed by new-age information channels where misinformation and biases spread at lightning speed.

The choice of information channels have an impact on supply chain risk management: 78 percent of the Fortune 500 companies source raw materials globally. Combine this with practices like lean management that have led to reduction in inventories and rise in unpredictable weather events, one gets the need for a reliable information source in managing supply chain risk.

However, people continue to be ambivalent over their choice of information channel. More often than not, familiarity of an information source trumps over its inherent trustworthiness. This is demonstrated by the fact that despite the rise of automation and availability of information, nearly one-third of companies around the world have not analyzed their full supply chain to identify original source of disruption.

In this age of information overload, even the risk management tools are in the danger of becoming online echo chambers -- an over reliance on them is not a good idea because of the absence of effective feedback loop. In order to avoid such a scenario, supply chain risk managers would need access to a third-party risk information provider who will act as an independent arbitrator for providing unbiased and timely information to prevent disruptions.

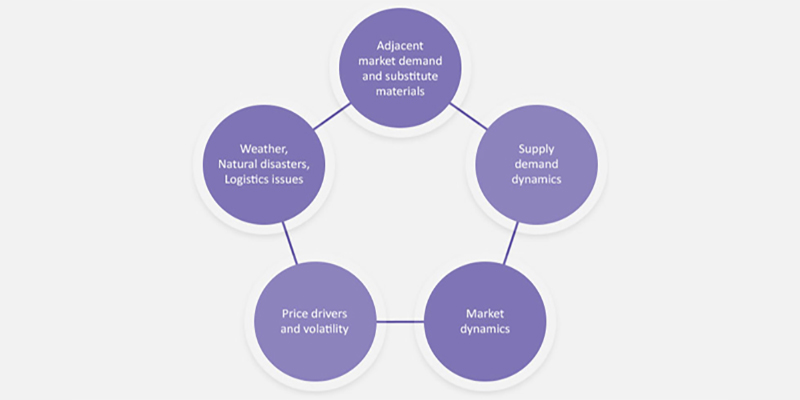

The intelligence partner should not only analyze the supply chain in isolation but also the entire ecosystem for meaningful results. The independent arbitrator will interpret information relating to:

- Adjacent market demand and substitutes

- Supply demand dynamics

- Market dynamics

- Price drivers and volatility

- Weather, natural disasters and logistics issues

By triangulating information flow from all of the above nodes, the independent arbitrators will be able to provide timely, relevant risk alerts to supply chain managers. This will ensure not getting stuck into echo chambers or falling prey to self-fulfilling prophecy because mere availability of data and peer opinion doesn’t guarantee a favorable outcome. What matters is emotion-free interpretation of the data in a timely manner: that’s how one can deftly manage supply chain risk in the post-truth world.

Once the required information has been collated and the risks have been identified, the following mitigation plans can be adopted.

|

Major Risks |

Strategy |

Description |

|

Supply Disruption, Price |

Risk Source, Risk Assess, Risk Mitigate |

Identify the risk source, assess the impact based on scenario planning (“what if” type of questions) and mitigate or transfer the risk accordingly. |

|

Supply Disruption, Opportunistic Behavior of Supplier |

Off Shore & Near Shore |

Main supplier is a single source supplier either offshore or near shore. The alternative supplier is a pre-qualified near shore supplier with buffer capacities. |

|

Inventory and Scheduling, Quality |

Information Management Systems |

Maintain a central hub of information relating to a particular supplier such as supplier contracts with different manufacturing locations of the company, supplier performance indices by each manufacturing location |

|

Lack of Innovation, Quality, Opportunistic Behavior of Supplier |

De-risking sourcing |

Governance: Retention of Control: Maintaining the right level of control over outsourcing facilitates better risk management. |

|

Technology, Quality |

Vendor Managed Inventory |

A risk transfer strategy which results in more efficient supply chain as the supplier manages the entire chain, and is responsible for disruptions at any tier level |

Related Insights:

View All

Get more stories like this

Subscirbe for more news,updates and insights from Beroe